Well cementation two-interface cementing quality evaluation device and method

A quality evaluation and interface adhesive technology, applied in construction and other directions, can solve the problems of not considering liquid, unable to evaluate the sealing ability of formation fluid, unable to reflect the quality of cementing interface bonding, etc., to achieve good anti-separation effect and prevent overall slippage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below according to the accompanying drawings, so that those skilled in the art can understand the present invention. However, it should be clear that the present invention is not limited to the scope of specific implementations. For those of ordinary skill in the art, as long as various changes are within the spirit and scope of the present invention defined and determined by the appended claims, they are all within the scope of protection. List.

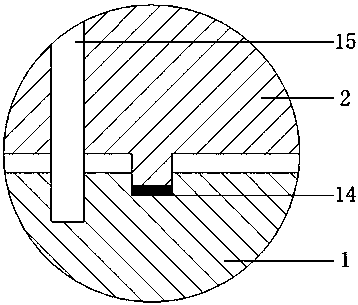

[0038] Such as Figure 1-2 shown.

[0039] The cementing quality evaluation device for the second cementing interface is composed of a cylindrical kettle body 1, a rock core 4, a heating jacket 5, a heat preservation jacket 8, a fluid booster pump 11, a pressure sensor 12, and a pressure recorder 13.

[0040] The inner diameter of the kettle body 1 gradually decreases from the top to the bottom, and the inner wall forms a rounded table shape. The kettle body has a detachable u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com