PFA material and preparation method thereof

A technology of dispersion liquid and boron nitride, which is applied in the direction of heat exchange materials, chemical instruments and methods, coatings, etc., can solve the problems of reduced effective breakdown field strength and uneven structure of PFA materials, so as to improve ESD shock resistance Wear characteristics, reduce accumulation, enhance the effect of thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following descriptions of the various embodiments refer to the accompanying drawings to illustrate specific embodiments in which the invention may be practiced. The directional terms mentioned in the present invention, such as [top], [bottom], [front], [back], [left], [right], [inside], [outside], [side], etc., are only for reference The orientation of the attached schema. Therefore, the directional terms used are used to illustrate and understand the present invention, but not to limit the present invention. In the figures, structurally similar elements are denoted by the same reference numerals.

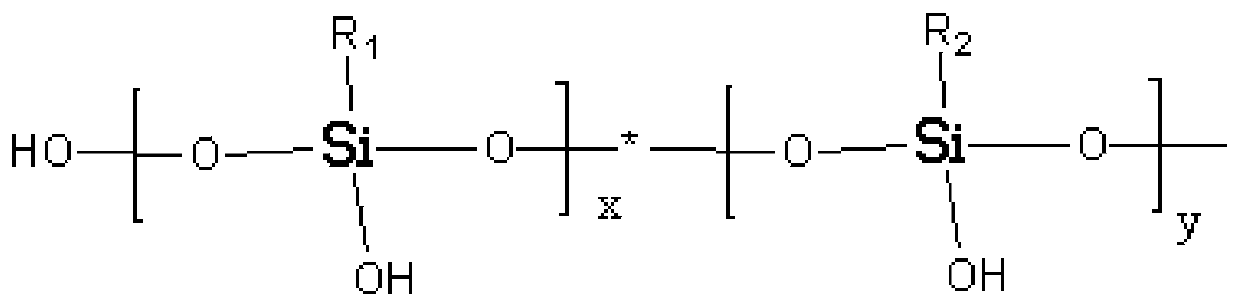

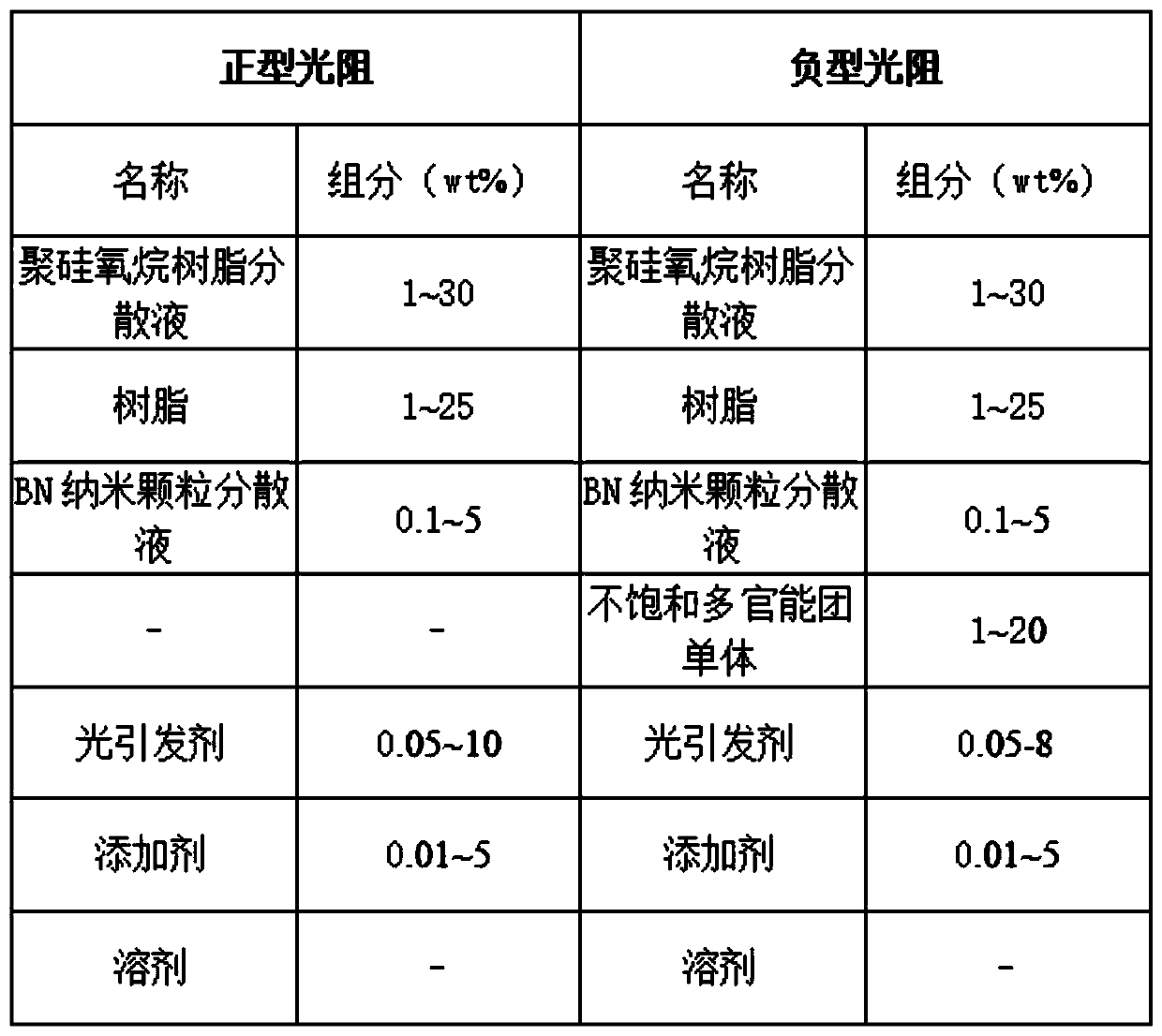

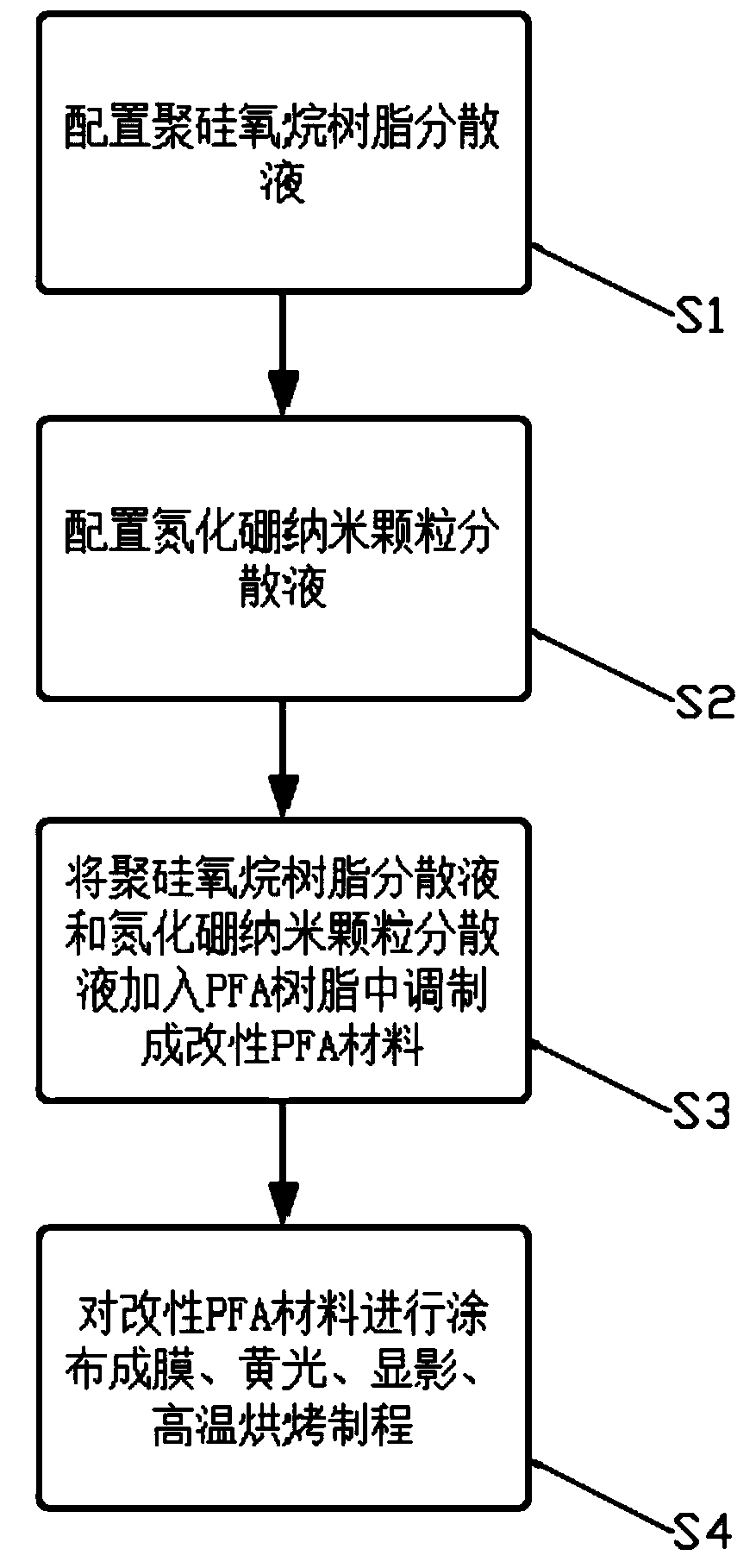

[0031] The invention provides a PFA material and a preparation method thereof, which can simultaneously ensure the dispersion and the uniformity of the electric field, so as to solve the problem that the effective breakdown field strength of the PFA material is greatly reduced due to the uneven structure and the uneven electric field of the existing PFA material questi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com