A tbm cutter head hob cutter seat replacement positioning detection device

A technology of positioning detection device and cutter head, which is applied in auxiliary devices, workpiece clamping devices, auxiliary welding equipment, etc. Cost, simple structure, and the effect of improving replacement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is described in conjunction with accompanying drawing and specific embodiment:

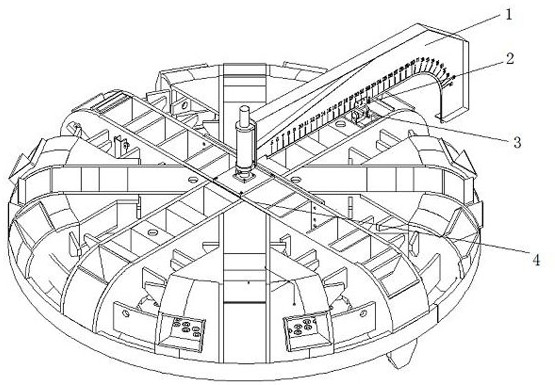

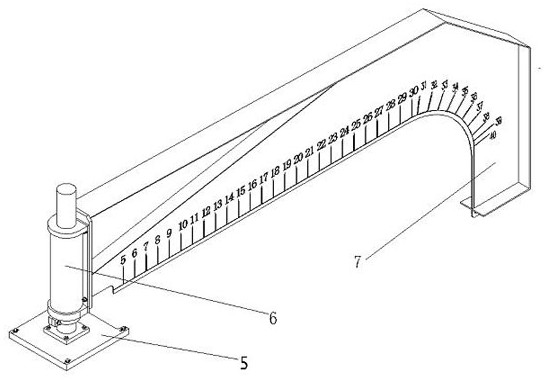

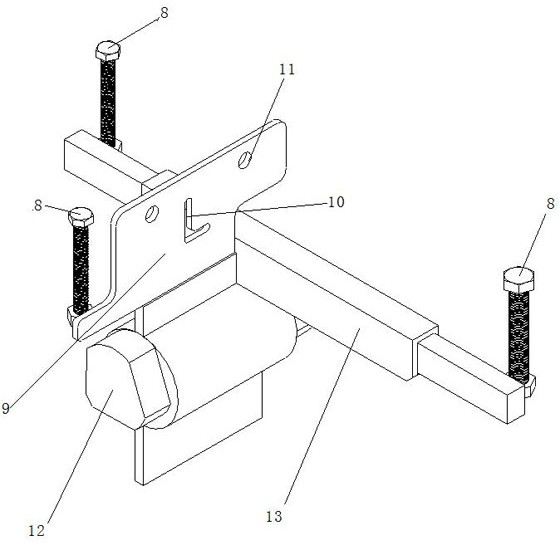

[0018] Such as figure 1 As shown, a TBM cutterhead hob tool seat replacement positioning detection device, the positioning detection device has a rotating shaft 6 arranged at the center of the cutter head 4; the rotating shaft 6 is arranged perpendicular to the cutter head 4; the The rotating shaft 6 is connected with a level ruler 1; figure 2 , the level 1 has a horizontal rod arranged horizontally; one end of the horizontal rod is connected to the rotating shaft 6, and the other end stretches out from the cutter head 4 and is bent downward to form an L-shaped level; The horizontal scale is marked with the vertical scale line 20 of the standard knife spacing of the TBM cutter head hob; the horizontal scale line 21 is also marked on the level scale, and the height position of the horizontal scale line 21 corresponds to the working height of the hob blade, that is, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com