Refueling gripper capable of adapting to special-shaped operation head

A kind of operating head and special-shaped technology, which is applied in the direction of climate sustainability, reactor fuel elements, and reduction of greenhouse gases. adaptable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

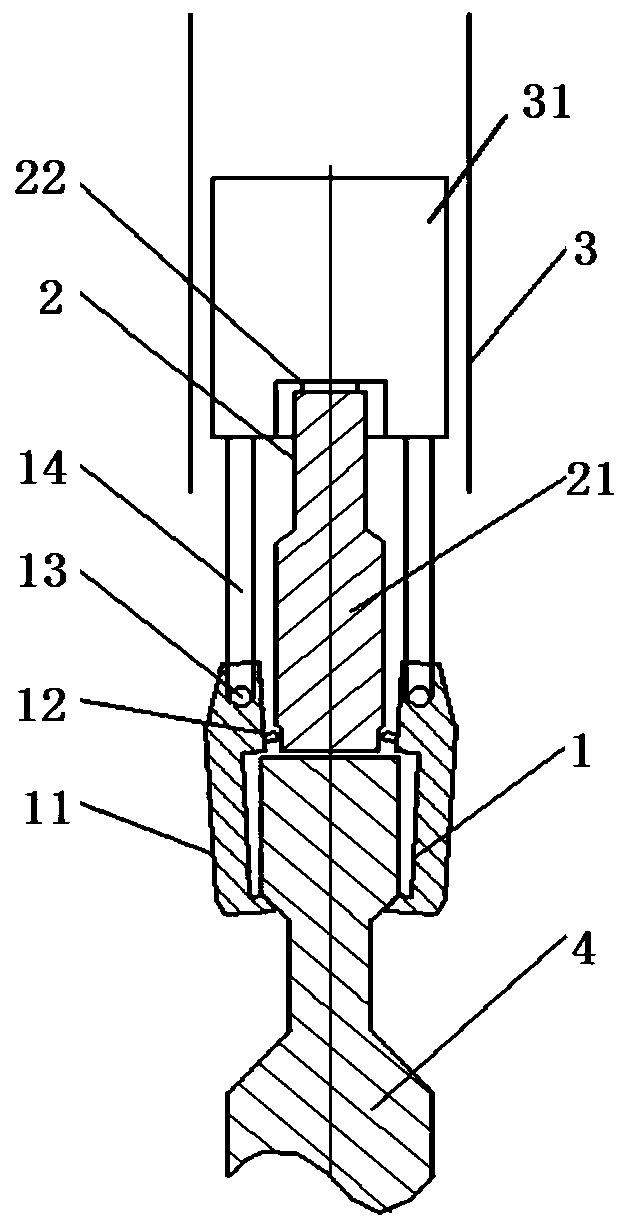

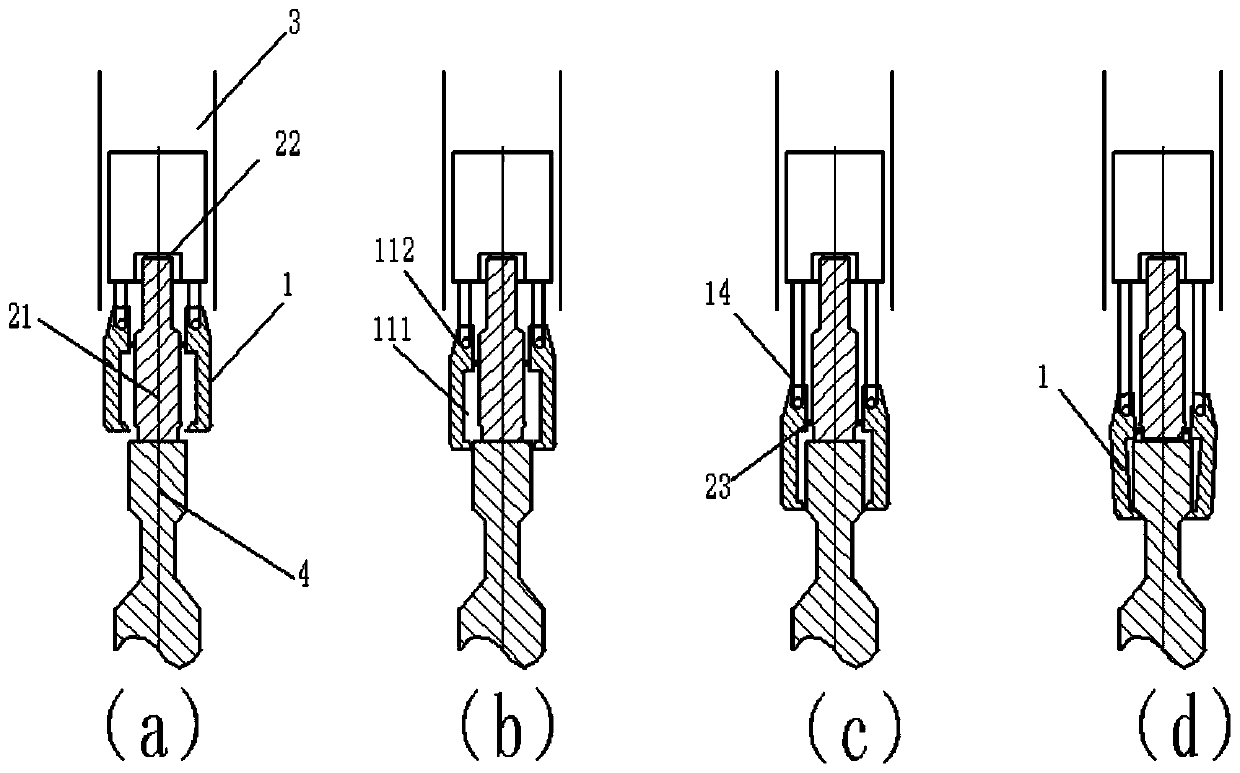

[0021] Such as Figure 1-2 As shown, a refueling gripper adaptable to a special-shaped operating head in this embodiment includes a gripper 1 , a special-shaped gripper guide rod assembly 2 and a gripper lifting sleeve 3 . Among them, the gripper 1 and the special-shaped gripper guide rod assembly 2 are all arranged at the lower end of the inner cylinder 31 of the gripper lifting sleeve 3, and the lifting and falling of the fuel can be realized through the gripper lifting sleeve 3, so that fuel can be added and replace.

[0022] The gripper 1 includes jaws 11 , cams 12 , connecting pins 13 and telescopic rods 14 . There is a pair of telescopic rods 14. Three telescopic rods 14 are symmetrically distributed on the outer side of the special-shaped gripper guide rod assembly 2 at the lower end of the inner cylinder 31. Cams 12 are respectively provided. Further, the jaw 11 includes a clamping portion 111 and a connecting portion 112; the clamping portion 111 cooperates with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com