Double-sided display panel

A double-sided display and panel technology, which is applied in the manufacture of electrical components, electrical solid devices, semiconductor/solid devices, etc., can solve the problems of high overall energy consumption, large thickness of the whole machine, gap in brightness and contrast, etc., and achieve double-sided display display effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Please refer to Figure 1 to Figure 4 , Embodiment 1 of the present invention is:

[0040] Please refer to figure 1 , a double-sided display panel, comprising a pixel structure, the pixel structure comprising two or more pixel units 2 and groups 1 with the same structure, and more than two pixel units 2 and groups 1 are arranged in an array;

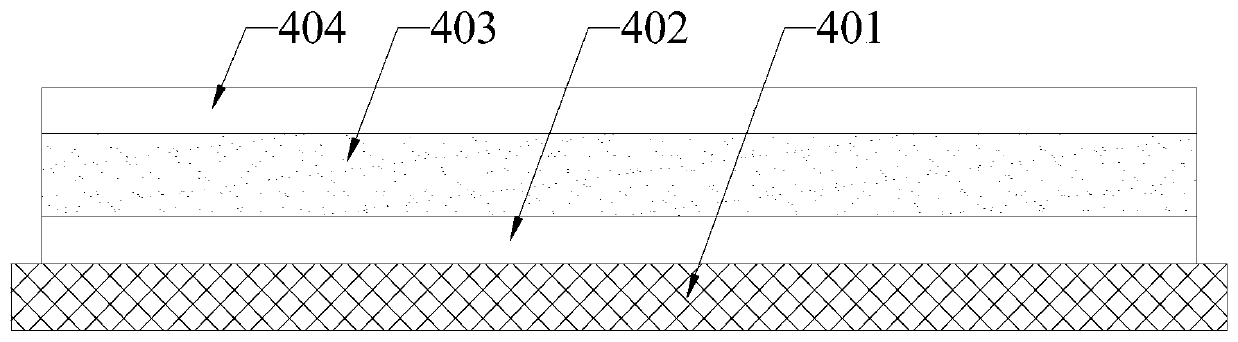

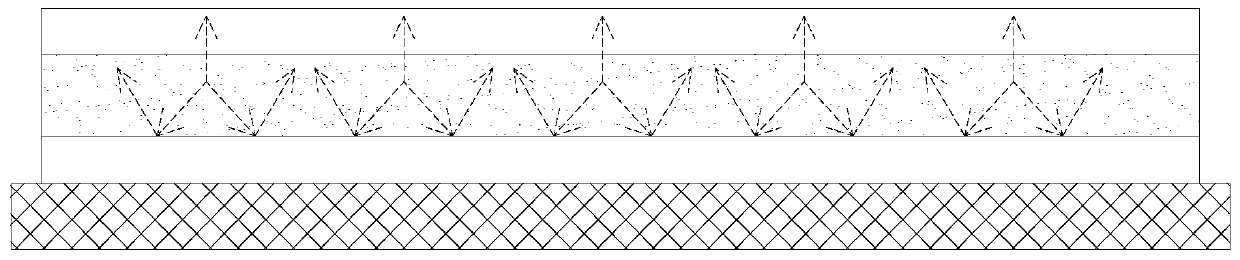

[0041] Each pixel unit 2 group 1 includes three pixel units 2, and each pixel unit 2 includes a TFT device 3 and a main pixel 4, and each pixel unit 2 in the same pixel unit 2 group 1 The main pixels 4 are different, they are B pixels displaying blue, G pixels displaying green, and R pixels displaying red, and the TFT device 3 is electrically connected to the main pixel 4; since the TFT device 3 and the main pixel 4 are not in The same structural layer, so a via hole is opened on the structural layer between the TFT device 3 and the main pixel 4, through which the wire can connect the TFT device 3 to the main pixel 4; each group...

Embodiment 2

[0053] Please refer to figure 2 , the second embodiment of the present invention is:

[0054] The difference between the second embodiment and the first embodiment is that the material of the metal anode layer 402 is ITO and the thickness of the metal anode layer 402 is 0.55 μm.

[0055] To sum up, in the double-sided display panel provided by the present invention, the metal anode layer and the metal cathode layer are set as transparent film layers so that the light generated by the organic light-emitting layer can pass through the metal anode layer and the metal cathode layer to be emitted respectively, so that The panel can realize double-sided light emitting function, so as to realize the double-sided display of the panel; the display panel designed in this scheme can significantly reduce energy consumption while improving the brightness and contrast of the panel screen.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap