Wind power generation foundation-based photovoltaic power generation device and installation method thereof

A technology based on wind power generation and photovoltaic power generation, applied in the field of solar power generation, can solve the problems of increased time cost, high labor intensity, long working hours, etc., and achieve the effects of preventing power loss, reducing labor intensity, and reducing labor force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] Embodiment 1 A photovoltaic power generation device based on wind power generation

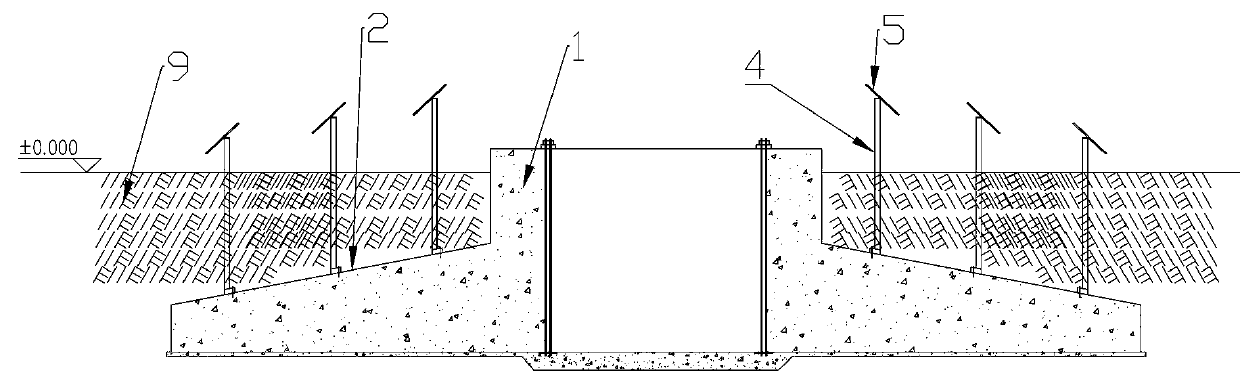

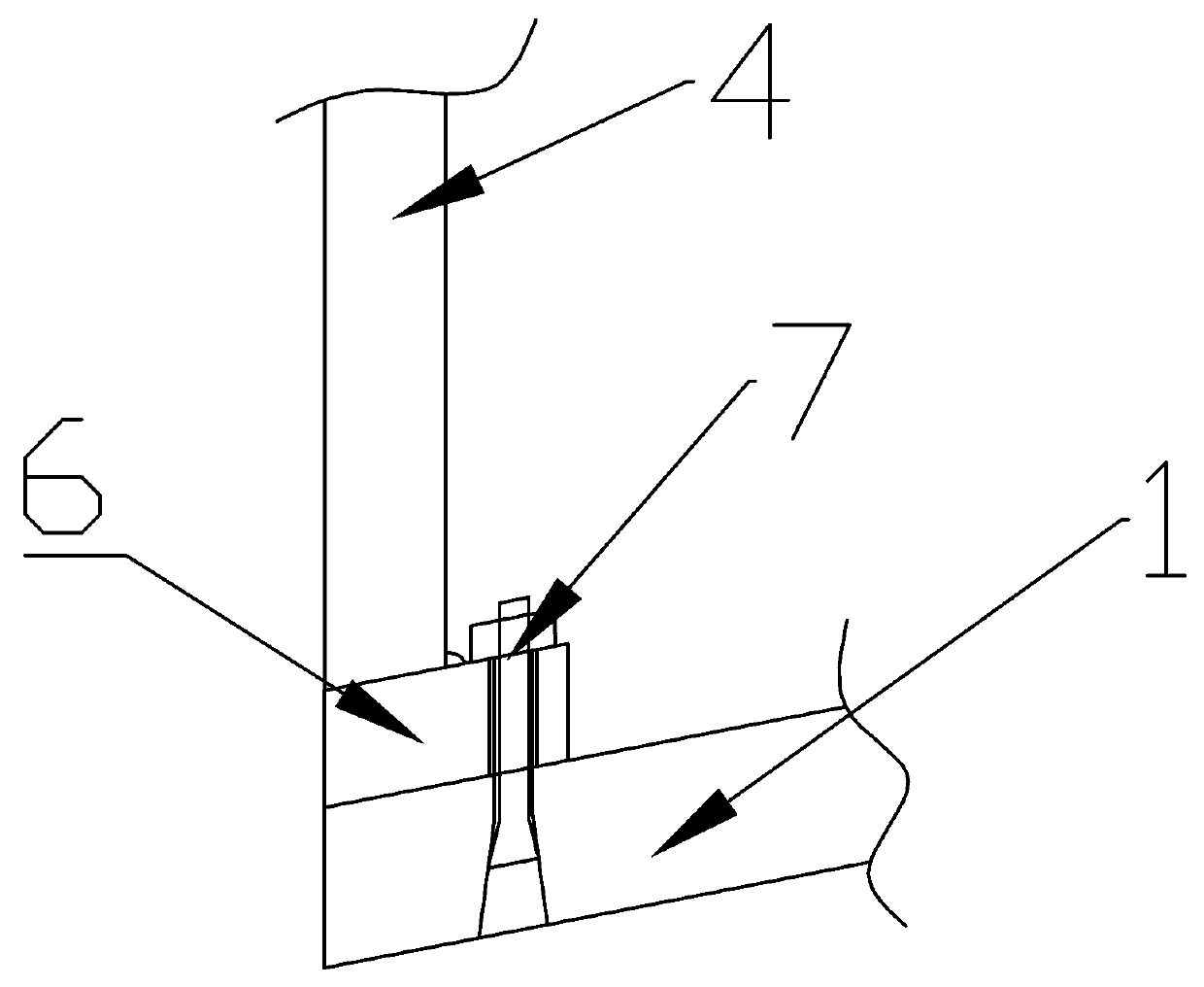

[0065] Such as Figure 1 to Figure 3 As shown, in this embodiment, the wind power generation base 1 is used as the foundation for solar power generation, and steel piles 4 of photovoltaic panels 5 are laid on the wind power generation base 1 .

[0066] The wind power generation base 1 is placed underground and is a conical concrete wind power generation base. The curved surface (that is, the slope) of the wind power generation base 1 is circular, and the circular slope of the wind power generation base 1 is divided into a lighting area 2 and an inspection area 3 .

[0067] (1) Inspection area 3

[0068] The maintenance area 3 is fan-shaped, and the maintenance area 3 is located on the north side. It cannot receive direct sunlight and is the shadow area of the photovoltaic panel 5. Therefore, there are no photovoltaic panels 5 and steel piles 4 in this area, which can be used for equ...

Embodiment 2

[0074] Embodiment 2 An installation method of a photovoltaic power generation device based on wind power generation

[0075] This embodiment is a method for installing a photovoltaic power generation device based on wind power generation in Embodiment 1, including the following steps:

[0076] Step 1: Divide the installation area

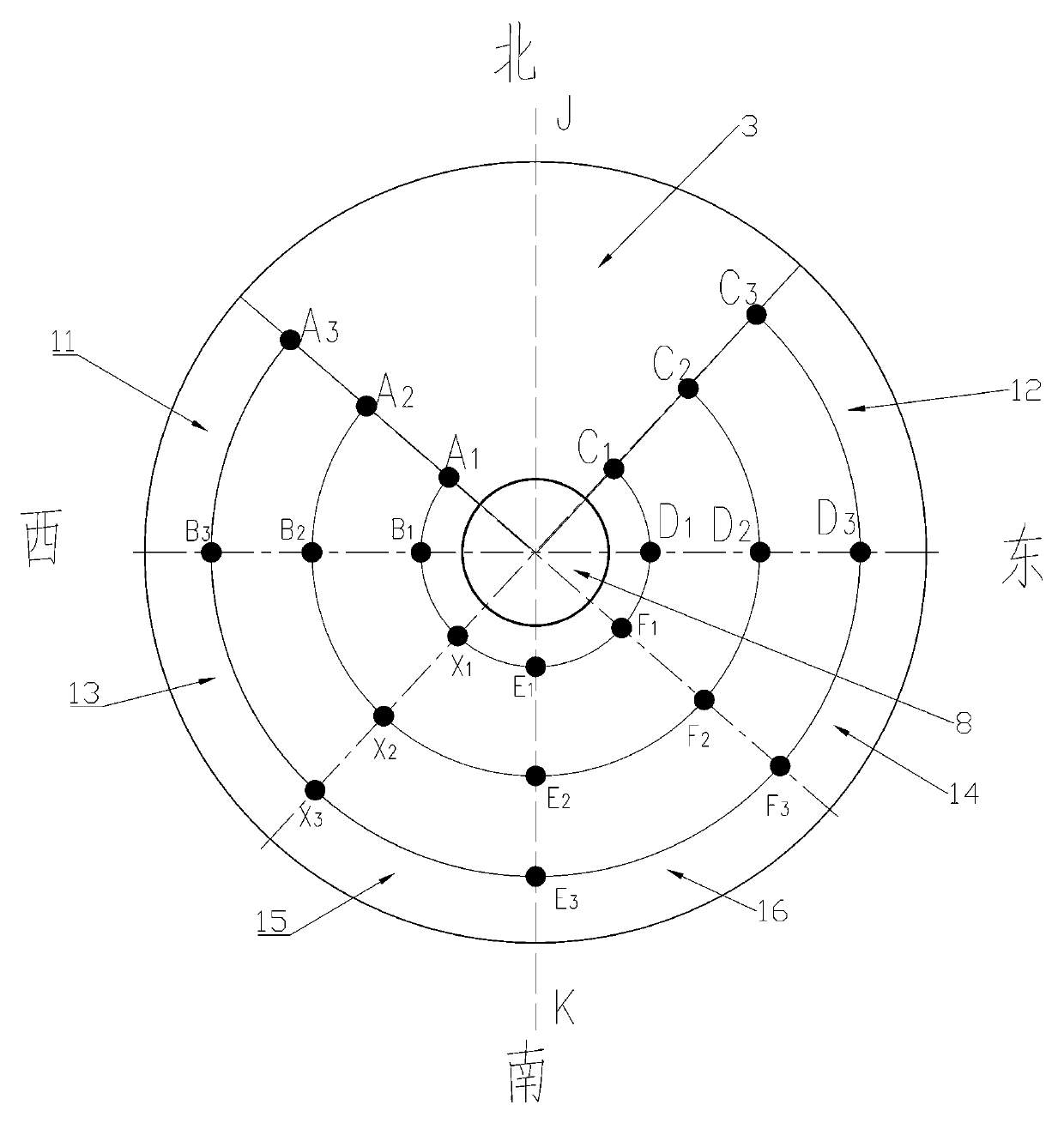

[0077] Divide the circular fan-shaped lighting area on the conical wind power generation base 1 into the first sector 11, the second sector 13, ... the (n)th sector, a total of (n) groups of sectors, where n≥2. And also meet the following conditions:

[0078] When n is an even number, the first sector 11 and the second sector 12 are arranged symmetrically with respect to the symmetry axis of the sector inspection area, ..., the (n)th sector and the (n-1)th sector with respect to the sector inspection area Axis of symmetry set symmetrically;

[0079] When n is an odd number, the first sector 11 and the second sector 12 are arranged symmetrically w...

Embodiment 3

[0105] Embodiment 3 An installation method of a photovoltaic power generation device based on wind power generation

[0106] This embodiment is based on Embodiment 2, taking n=6, m=q=p=3. Can refer to image 3 As shown, specifically:

[0107] Step 1: Divide the installation area

[0108]Divide the circular fan-shaped lighting area 2 on the conical wind power base 1 into the first sector 11, the second sector 12, the third sector 13, the fourth sector 14, the fifth sector 15, and the sixth sector 16. And the first sector 11 and the second sector 12 are about the axis of symmetry JK of the sector inspection area 3 (such as image 3 shown in ), the third sector 13 and the fourth sector 14 are arranged symmetrically with respect to the symmetry axis JK of the sector inspection area 3 , and the fifth sector 15 and the sixth sector 16 are arranged symmetrically with respect to the symmetry axis JK of the sector inspection area 3 Symmetrical setting.

[0109] And, arc A 1 B 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com