Axial and radial hydrostatic gear pump with helical teeth and double arc teeth

A technology of hydraulic gear pump and static pressure support, which is applied in the field of hydraulic gear pumps to achieve the effect of reducing friction power consumption and contact surface wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

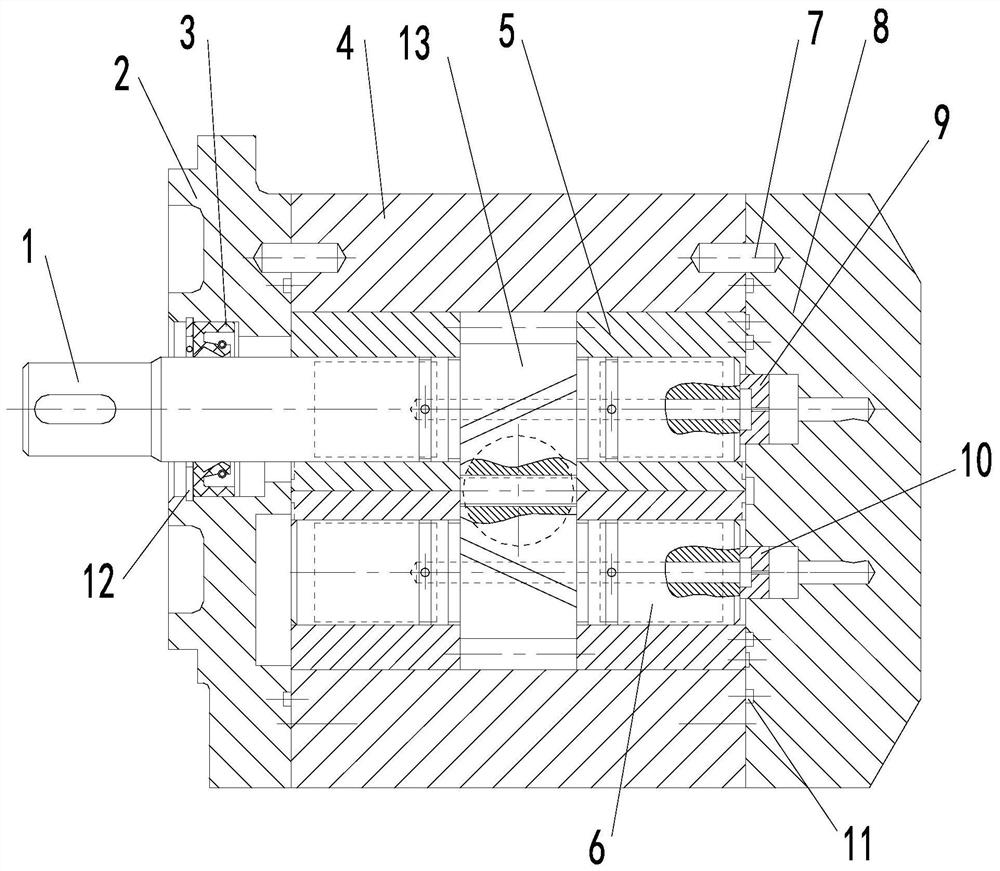

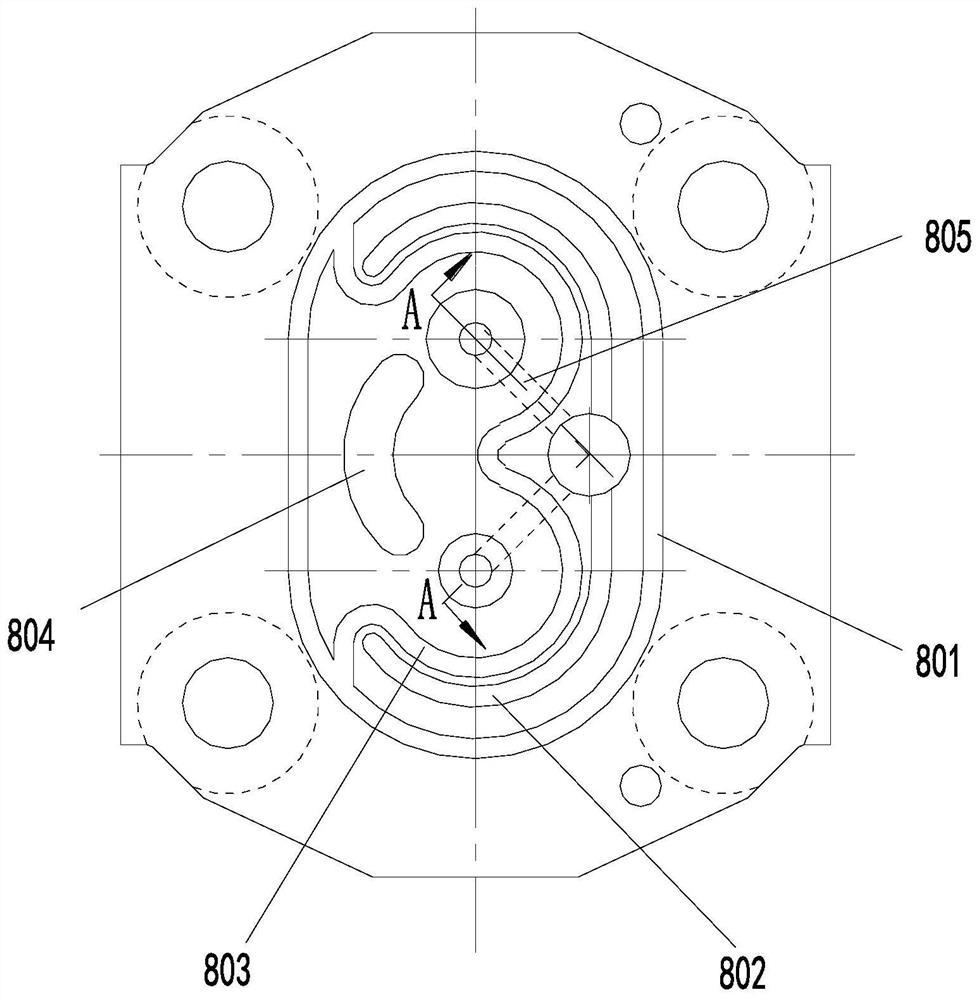

[0034] The invention solves the problems caused by the axial force and radial force in the working process of the helical double-arc tooth hydraulic gear pump. Its structure is as figure 1 As shown, it includes a pump body 4 , a driving gear shaft 1 and a driven gear shaft 6 . The two ends of the pump body 4 are respectively connected to the front end cover 2 and the rear end cover 8 by bolts 13, and are positioned by positioning pins 7. An O-ring 11 is arranged between the pump body 4 and the front end cover 2 and the rear end cover 8 . The gears on the driving gear shaft 1 and the driven gear shaft 6 mesh with each other and both are helical-toothed double arc toothed gears, both of which are arranged in the pump body 4 in parallel. A floating sleeve 5 is arranged between the driving gear shaft 1 and the pump body 4. One end of the driving gear shaft 1 is installed on the rear end cover 8 through a thrust sliding bearing 9, and the other end extends out of the front end co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com