A cold spray scribing machine

A marking machine, cold spray technology, applied in the direction of road, construction, road repair, etc., can solve the problems of skin damage, replacement trouble, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

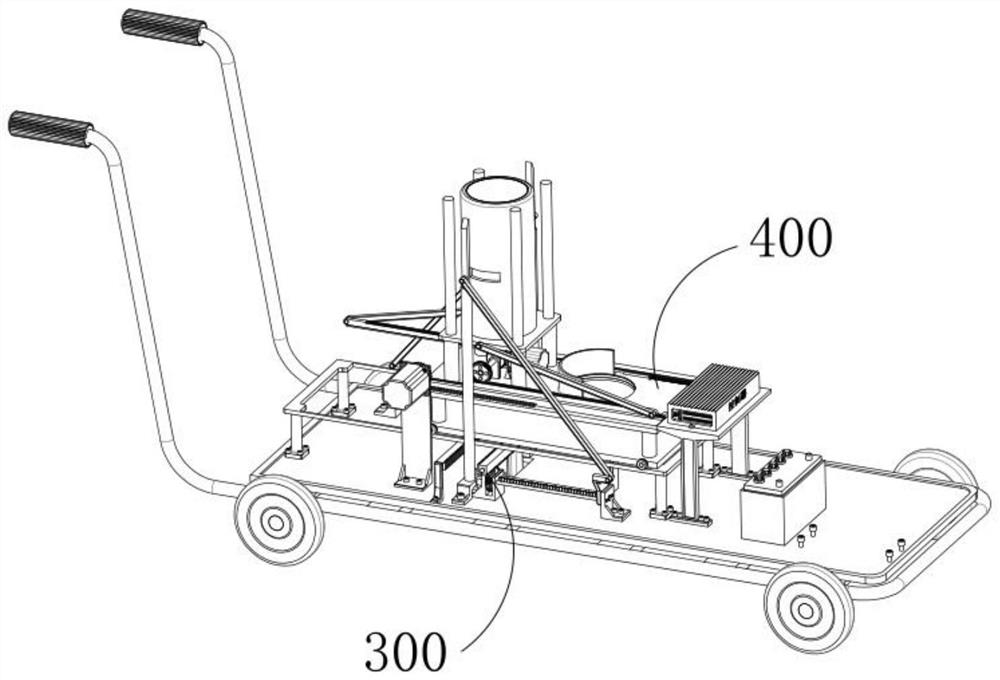

[0089] Compared with the existing marking machine, the present invention has the advantage that after the luminous paint in the luminous paint bucket is used up, it can automatically replace the luminous paint bucket with a new luminous paint bucket, which greatly improves the marking efficiency. The scribing efficiency of the line machine reduces the labor intensity of the staff. At the same time, the painting system of the line scribing machine can be separated from the connection with the replacement system when the replacement system is running, and does not interfere with the operation of the replacement system.

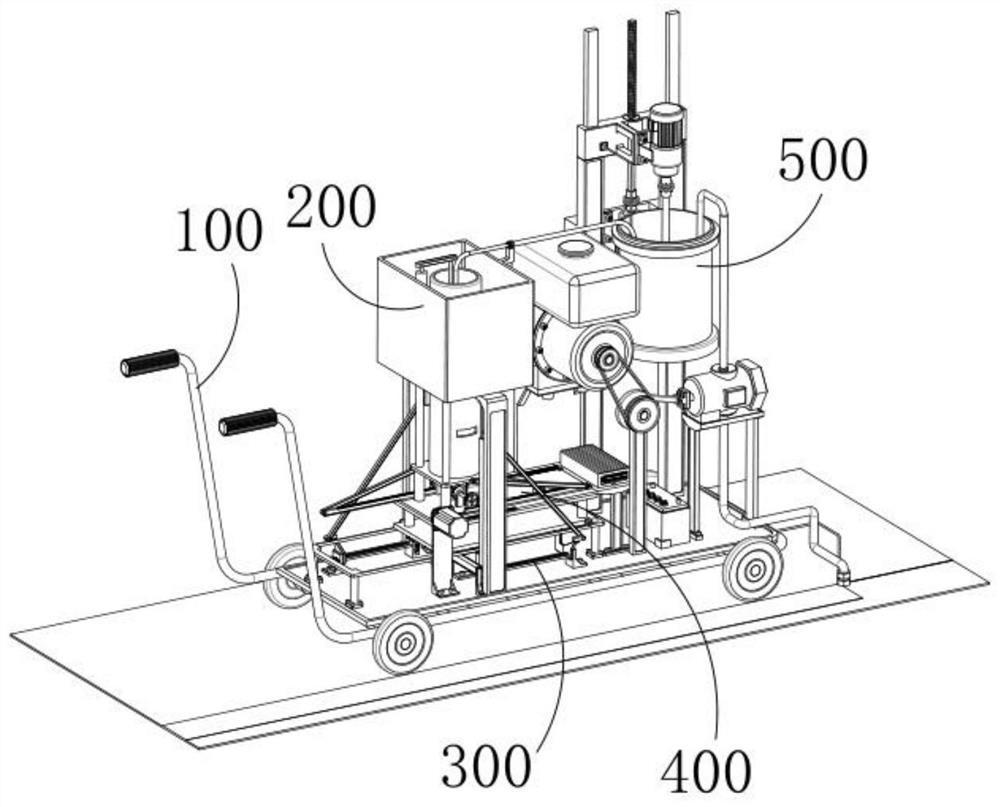

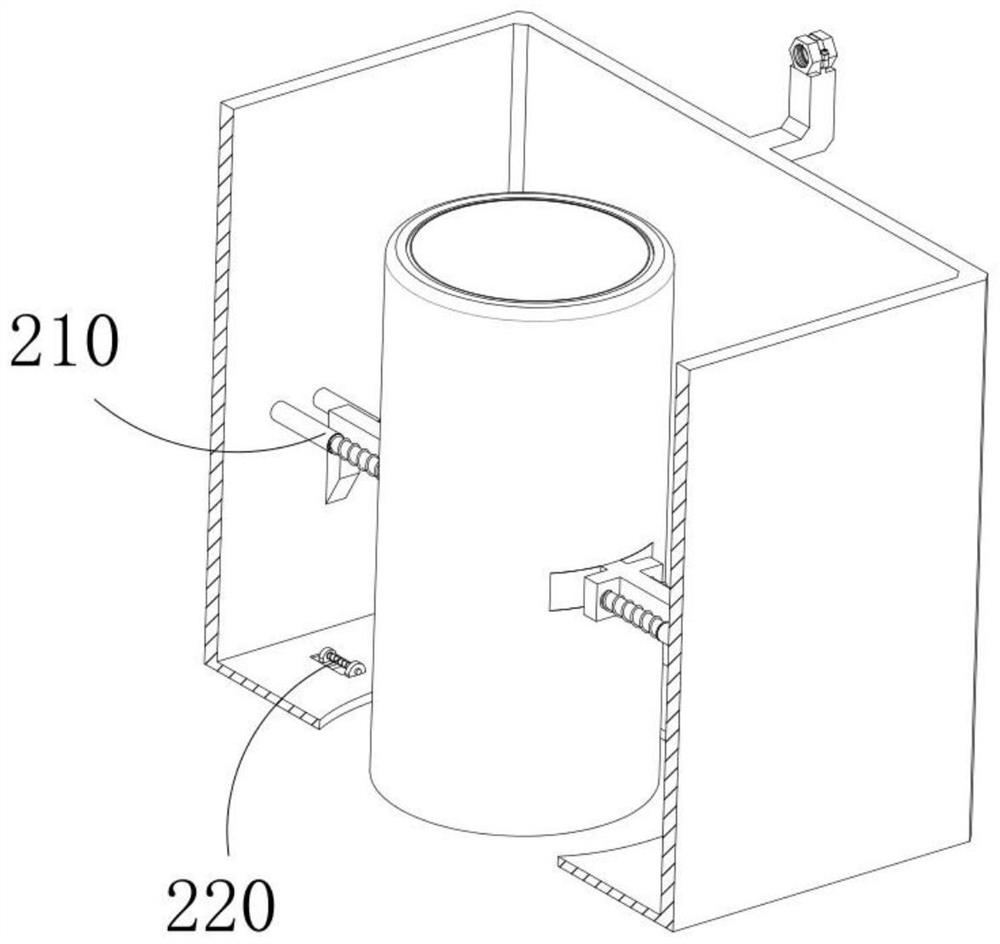

[0090] A cold spray marking machine, which includes a trolley body 100, on which an installation system, a replacement system, a paint spraying system, and a controller are installed, and the installation system is used to install the luminous paint bucket on the trolley body 100, and is used for the replacement system After the luminous paint bucket is used up, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com