Intelligent visual packaging system

An intelligent, packaging belt technology, applied in packaging, packaging protection, transportation and packaging, etc., can solve the problem that packaging belts cannot be accurately controlled, cannot improve the effective utilization rate and rapid conversion rate of social resources, and cannot adapt to a variety of products. Manufacturers, e-commerce, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below with reference to the accompanying drawings and examples.

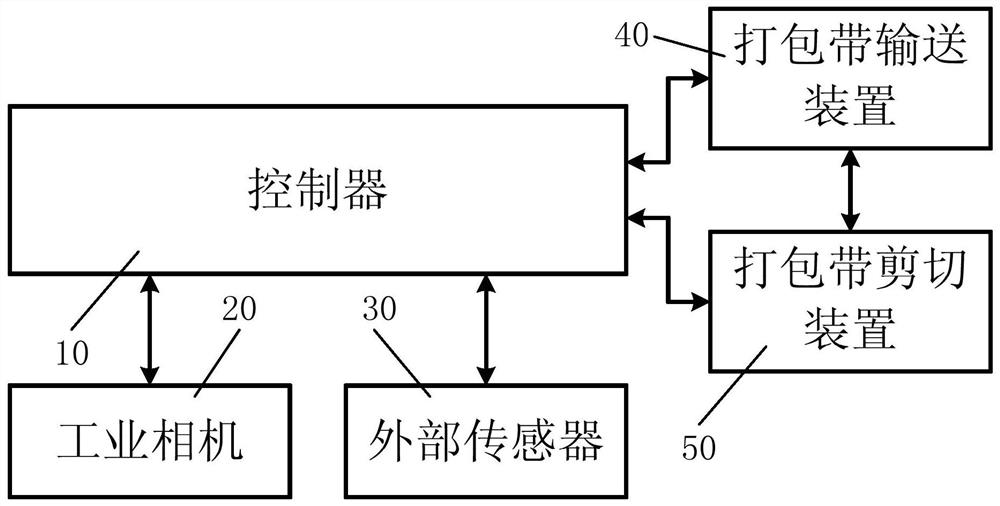

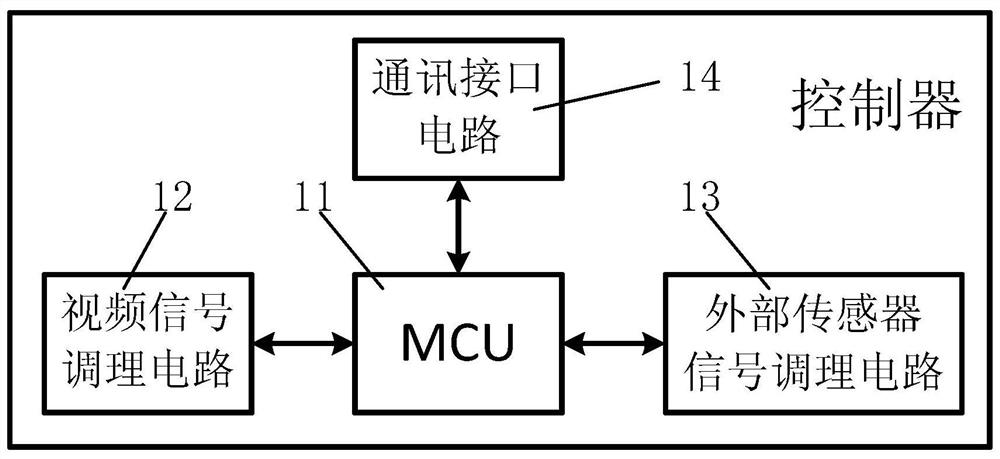

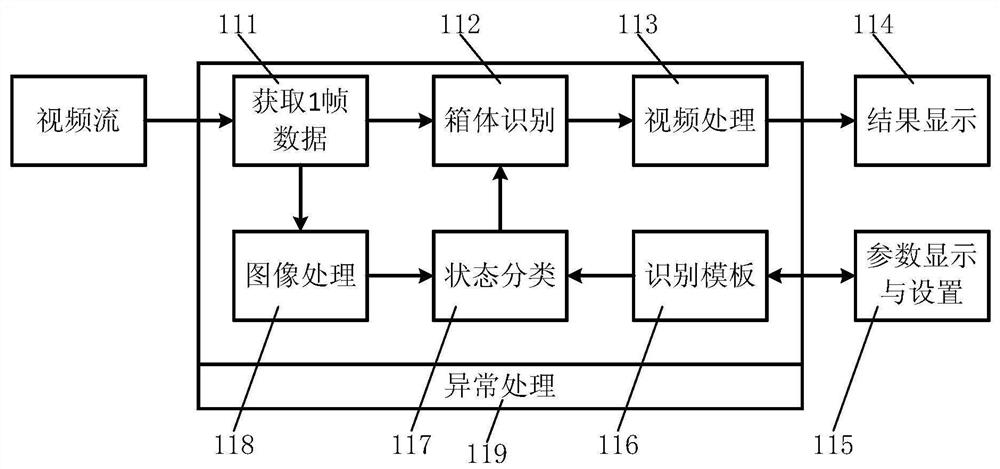

[0020] Such as figure 1 As shown, the intelligent visual packaging system proposed by the present invention is illustrated by packaging items in the express delivery industry. In the present invention, the intelligent visual packaging system is characterized in that it includes a controller 10, an industrial camera 20, an external sensor 30, a packing belt conveying device 40, and a cutting device 50, wherein the controller 10 receives the real-time images captured by the industrial camera 20. The information measured in real time by the video and the external sensor 30 identifies the state and size of the packaging box in the video. The external sensor 30 mainly measures the position of the packaging box on the conveyor belt in real time, and the controller 10 judges whether the packaging box is based on the position information of the packaging box. In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com