Semiconductor molding compound feeding device and working method thereof

A material guide device and molding compound technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., and can solve problems such as inaccurate position of the molding compound

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

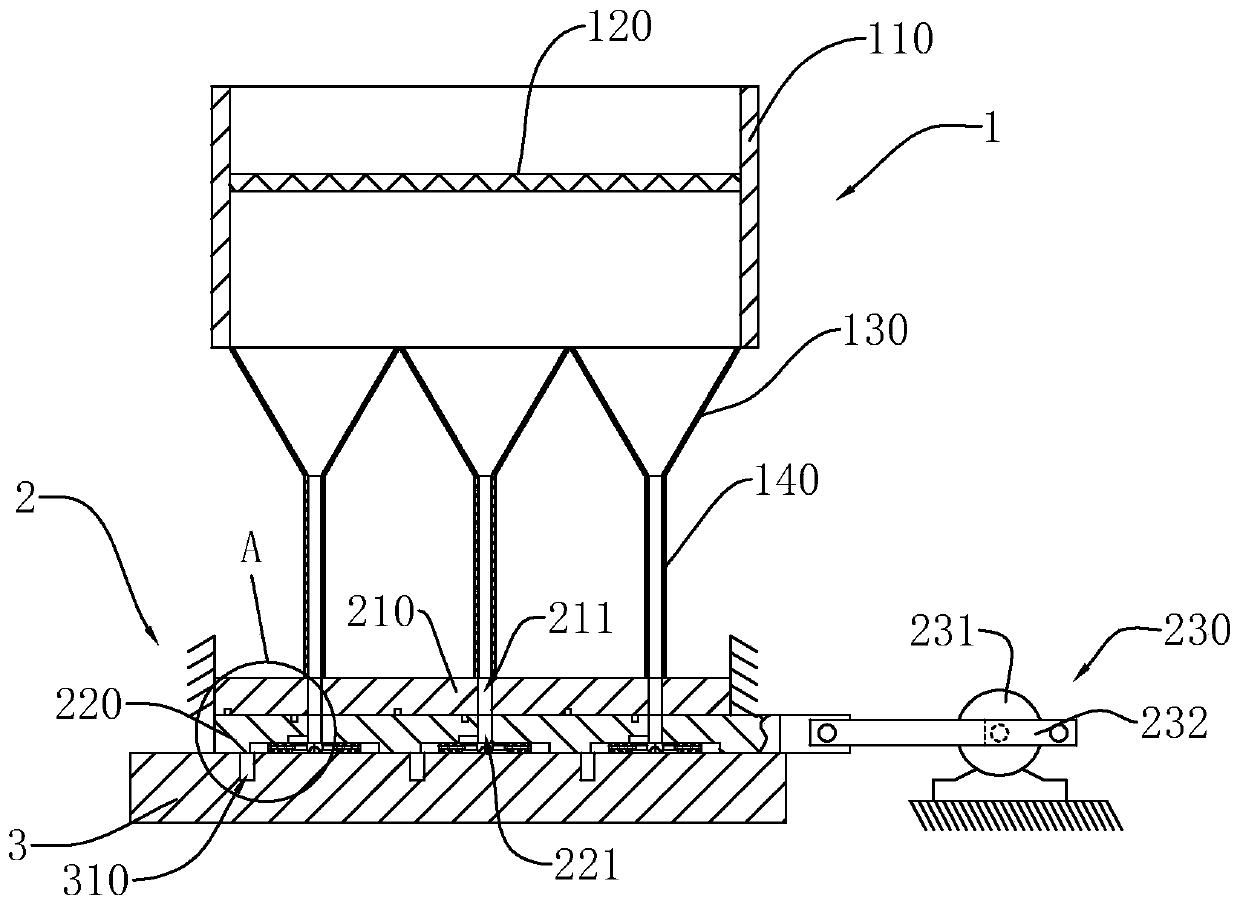

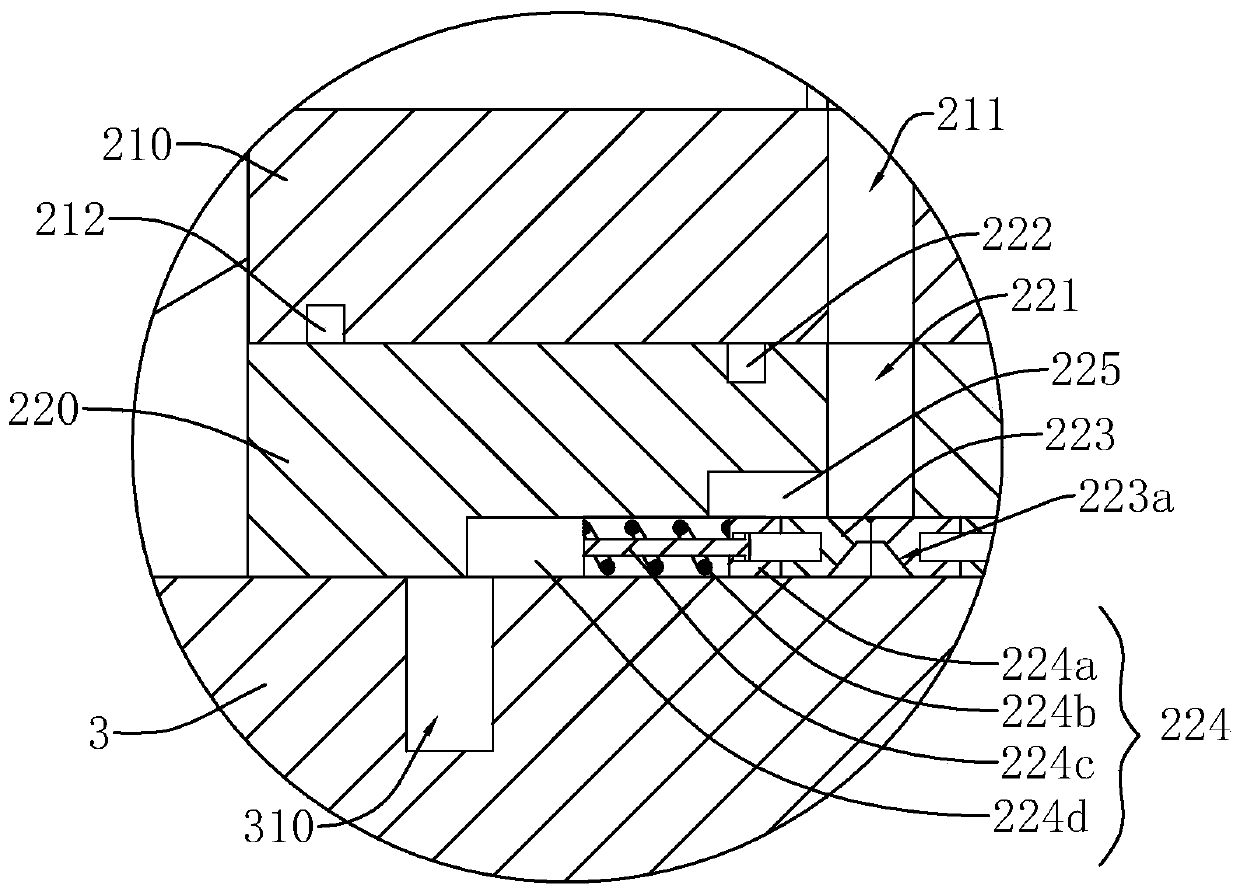

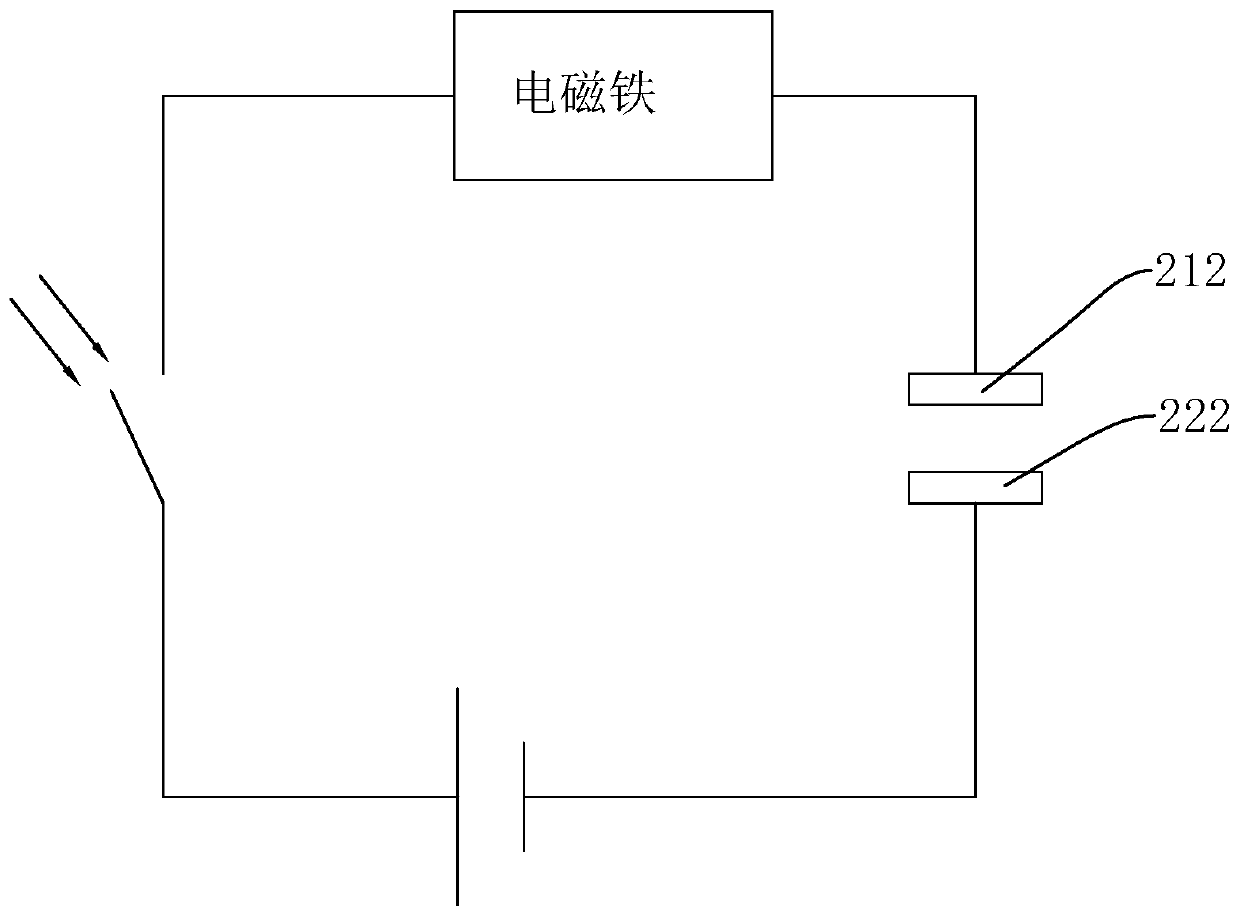

[0032] Embodiment 1, with reference to Figure 1-Figure 4, a semiconductor molding compound feeding device, including a distributing device 1, the distributing device 1 includes a hopper 110, a vibrating screen 120 arranged in the hopper 110, a funnel-shaped feeding device arranged below the vibrating screen 120 The hole 130 and the feeding pipe 140 communicated with the feeding hole 130 are characterized in that they also include a precise material guide device 2, and the precise material guide device 2 includes a horizontally placed upper material guide plate 210, and an upper material guide plate located on the upper material guide plate. 210 below the lower material guide plate 220, the upper material guide plate 210 is provided with a material receiving hole 211 facing the feeding pipe 140, and the lower material guide plate 220 is provided with a height corresponding to the material receiving hole 211 and The blanking hole 221 with the same thickness of the molding compo...

Embodiment 2

[0034] Embodiment two, refer to Figure 5-Figure 7 The upper material guide plate 210 is provided with a blanking hole 213, and a blanking device 228 is arranged in the blanking hole 213. The blanking device 228 includes a vacuum suction cup 228c, and a vacuum pump 228b is connected above the vacuum suction cup 228c. The top of the vacuum pump 228b drives the driving cylinder 228a that the vacuum chuck 228c moves up and down. The inner wall of the blanking hole 221 is provided with a photoelectric sensor 229. The control system is a controller, and the input terminal of the controller communicates with the photoelectric sensor 229 signal. The output ends of the controller are respectively connected with the driving mechanism 230, the power mechanism 224, the driving cylinder 228a and the vacuum chuck 228c. The power mechanism 224 is a discharge cylinder 224e, the drive mechanism 230 is a power cylinder 233, and the rest of the technical features are the same as those in the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com