Roller wheel distance adjusting apparatus and method

An adjustment device and adjustment method technology, applied in the direction of mold extrusion granulation, etc., can solve the problems of inconsistent spacing, inconsistent material thickness, inconsistent pressure transmission, etc., and achieve uniform granulation and uniform tablet thickness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

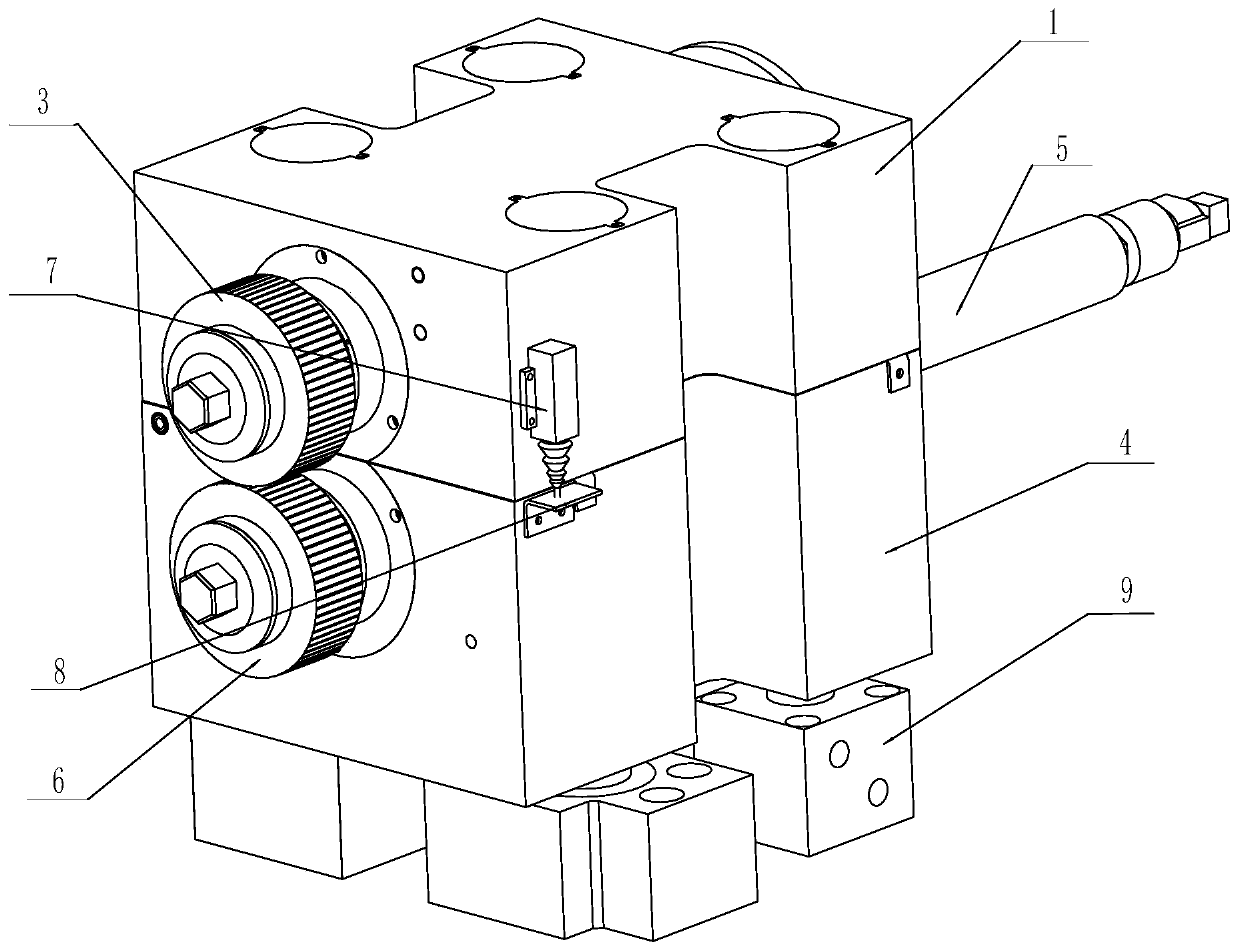

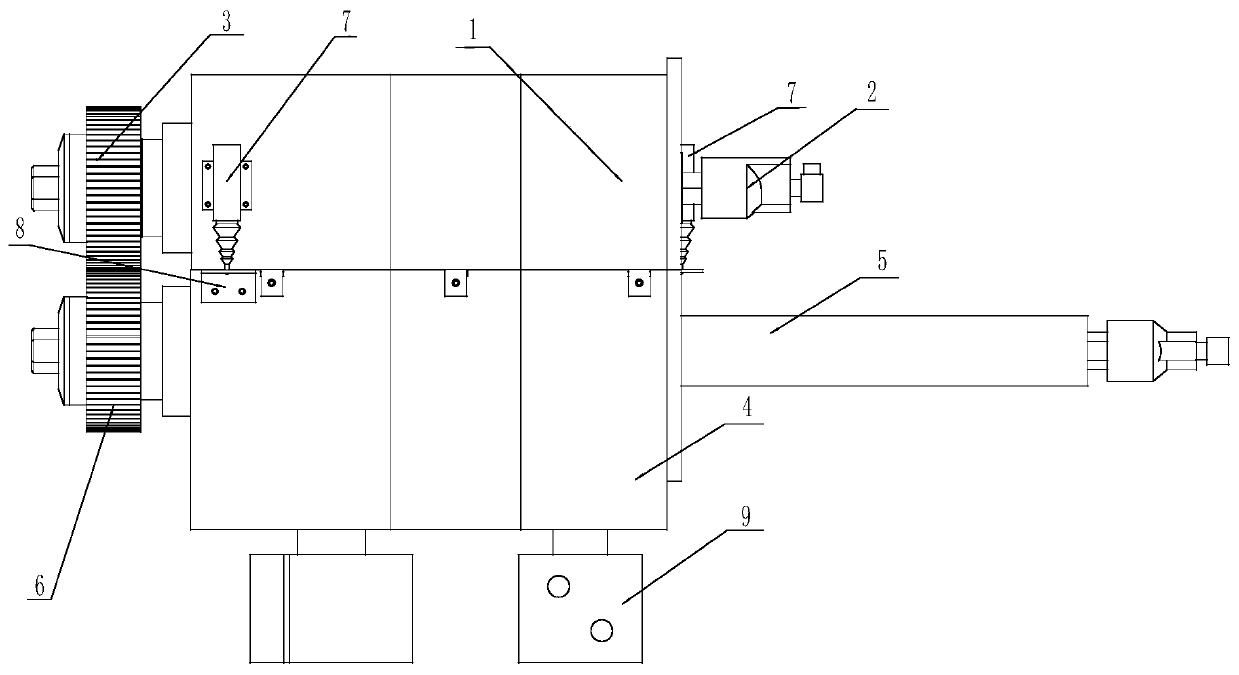

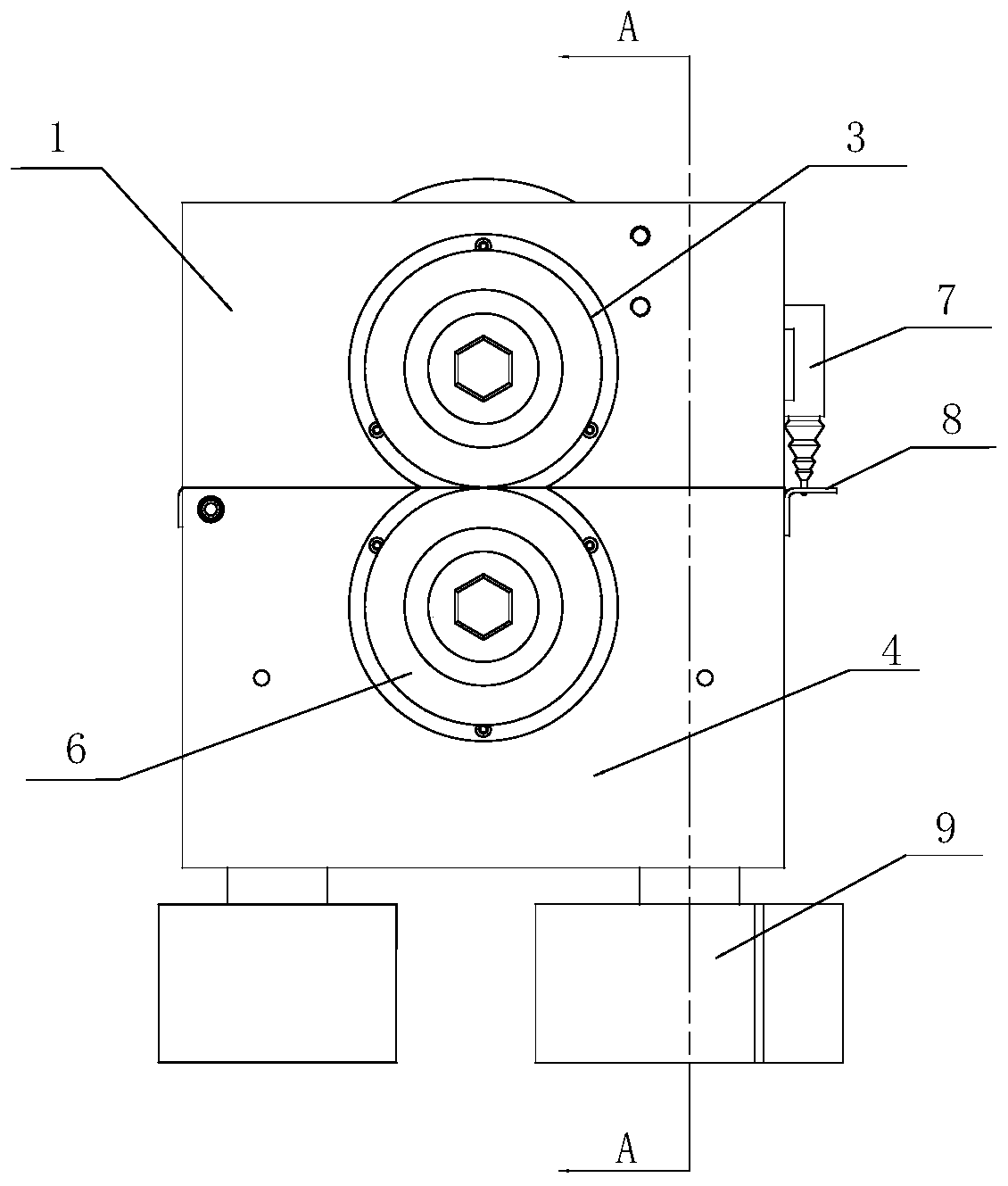

[0027] Such as Figure 1 to Figure 4 As shown, this embodiment introduces a rolling wheel spacing adjustment device, including a controller, an upper rolling wheel assembly and a lower rolling wheel assembly, the upper rolling wheel assembly includes an upper rolling wheel base 1, and the upper rolling wheel The wheel shaft 2 runs through the upper roller base 1, the front end of the upper roller shaft 2 is connected to the upper roller 3, the lower roller assembly includes the lower roller base 4, and the lower roller shaft 5 runs through the lower roller base 4. The front end of the lower roller shaft 5 is connected to the lower roller 6, the upper roller base 1 is located directly above the lower roller base 4, and the front and rear ends of the upper roller base 1 correspond to the lower roller The wheel bases 4 are all provided with displacement detection parts, and the front and rear ends of the upper roller press wheel base 1 are respectively provided with a group of ad...

Embodiment 2

[0034] Such as Figures 1 to 4 As shown, the method for adjusting the distance between the rolling wheels comprises the following steps:

[0035] Step 1: Monitor the front-end distance and the rear-end distance of the upper roller press wheel 2 and the lower roller press wheel 4 in real time and calculate the distance difference; the front-end distance and the rear-end distance are monitored in real time through the displacement sensor 7 and the monitoring data is transmitted to the controller The distance between the front end and the rear end detected by the displacement sensor 7 is calculated by the controller to obtain a distance difference, and compared with the preset value. The formula for calculating the spacing difference is: spacing difference = front-end spacing - rear-end spacing.

[0036] Step 2: Determine whether the gap difference exceeds the preset value. If the gap difference does not exceed the preset value, the adjustment mechanism remains unchanged. If the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com