Control method of dough mixer

A control method and dough mixer technology, applied to dough mixers, structural components of mixing/kneading machines, baking, etc., can solve the problems of complex control interface, cumbersome operation, unsatisfactory user experience, etc., and achieve simple operation mode , reduce manufacturing costs, and facilitate the use of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical scheme of the present invention is illustrated below in conjunction with accompanying drawing:

[0024] see Figure 4 , the control method of the dough mixing machine of the present invention, the dough mixing machine involved includes a mixing tank 1, a host 2, a knob key 3 arranged on a control panel on the host 2, a control unit and a display module 4, the mixing tank 1 A stirring member is provided, and the host 2 is provided with a heating element for providing heat to the mixing tank 1 and a motor connected to the stirring member. The knob key 3, the display module 4, the heating element and the motor are respectively connected to the The control unit is electrically connected, and the display module 4 is used to display the working information of the dough mixer.

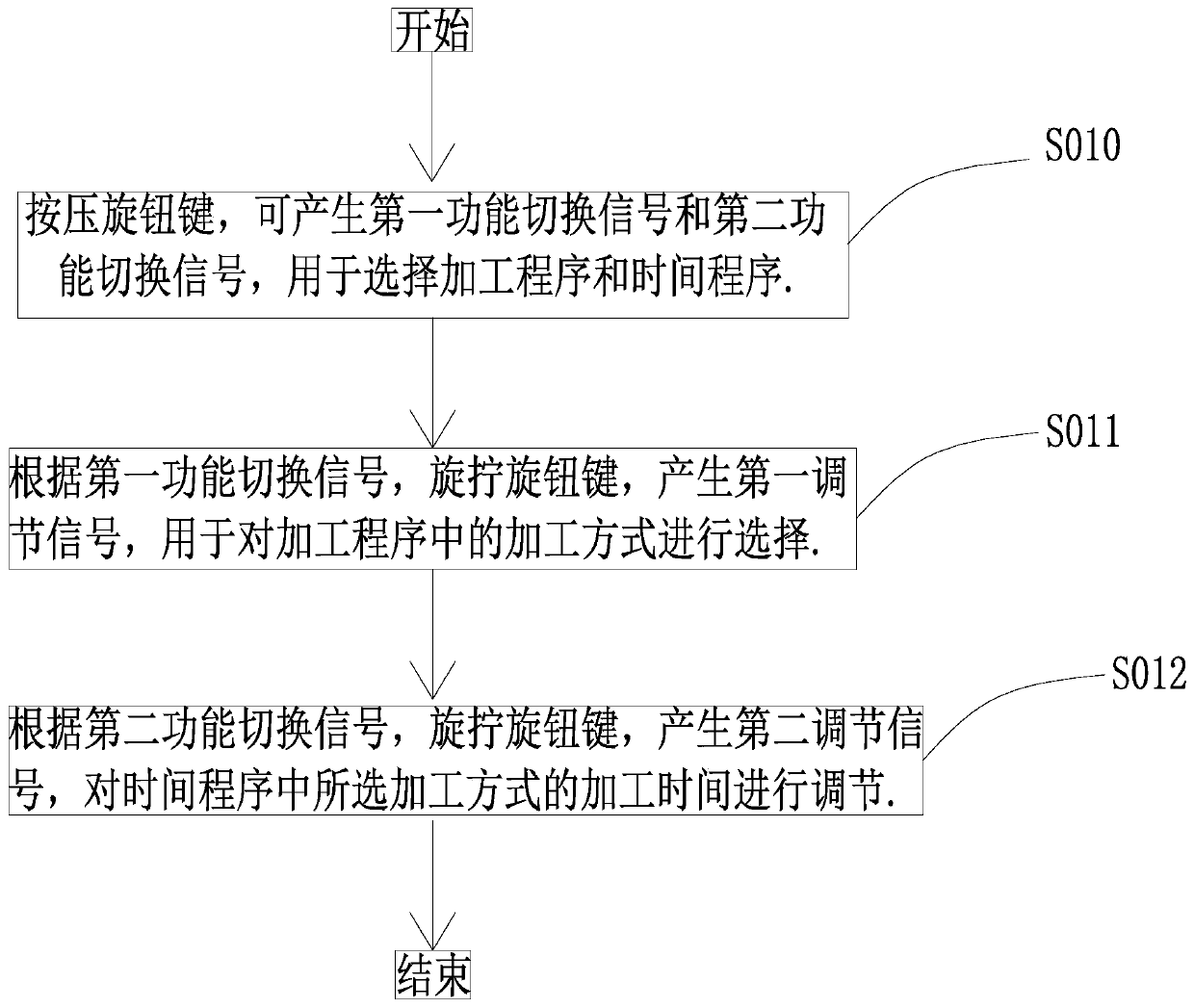

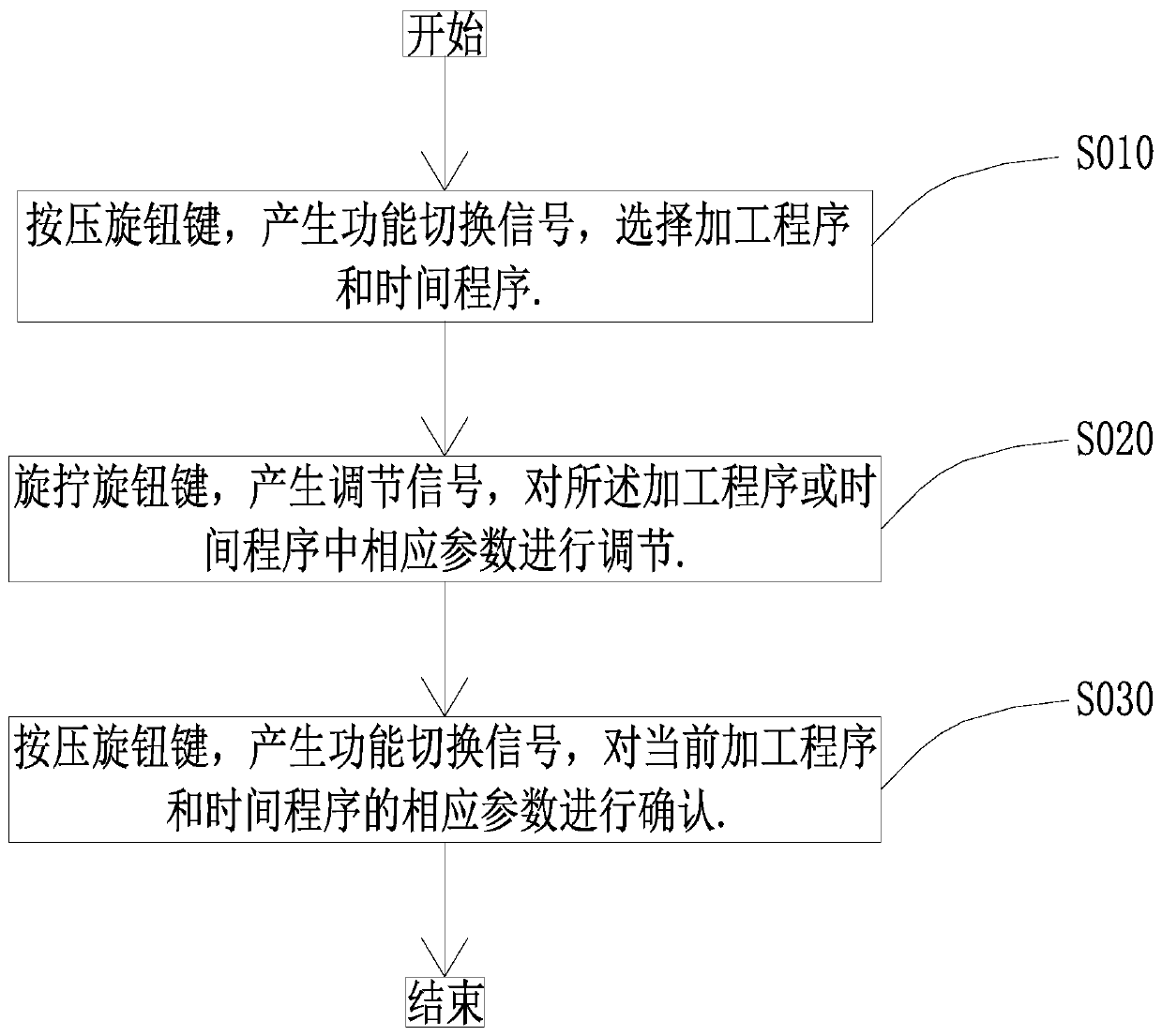

[0025] figure 1 It is a flow chart of the control method of the dough mixer according to one embodiment of the present invention. figure 1 As shown, the control method of the dough mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com