High-reliability motor end face static sealing structure

A static sealing and reliable technology, applied in electrical components, electromechanical devices, electric components, etc., to achieve the best thermal insulation effect and improve the thermal insulation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

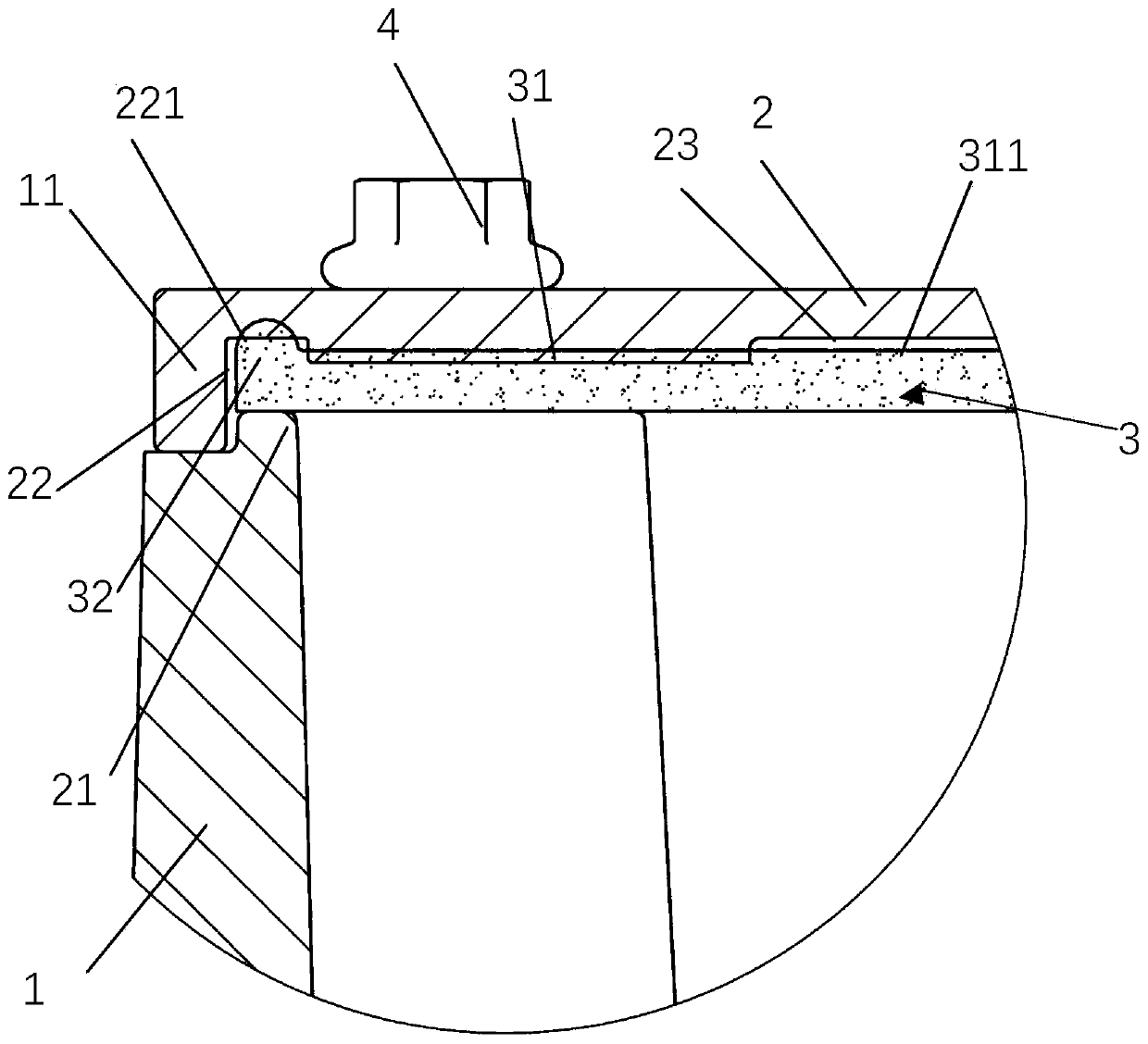

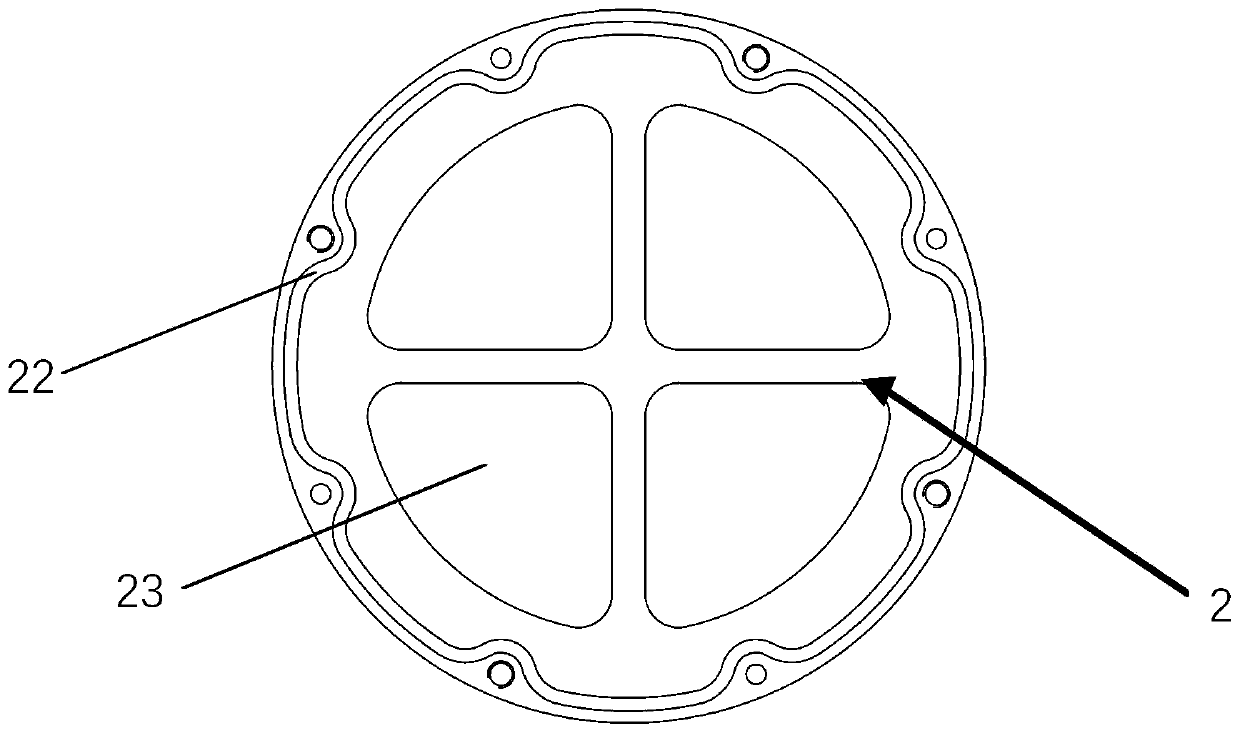

[0021] See attached Figure 1-2 As shown, a static sealing structure of the end face of a motor with high reliability, the static sealing structure of the end face is set between the housing 1 and the cover body 2 of the motor, and a ring of protrusions is provided on the port of the housing toward the cover body. Rib 11 , the cover body 2 is provided with a ring of convex edges 21 facing the housing 1 , when the cover body 2 is covered on the housing 1 through a pressing structure, the convex edges 21 are located on the outer periphery of the convex ribs 11 .

[0022] The cover body 2 is circular, and the cover body 2 is an end cover of the motor.

[0023] The pressing structure includes a first mounting hole provided on the cover 2, a second mounting hole and a mounting nail provided on the housing, and the cover 2 and the housing 1 pass through the first mounting hole and the second mounting hole. The holes are connected with the mounting nails 4; this compression structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com