Rapid molding device and method for standard similar material test piece

A technology similar to materials and molding methods, applied in the direction of analysis materials, preparation of test samples, measurement devices, etc., can solve problems such as loss of time, achieve simple structure, short time consumption, and improve the effect of preparation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

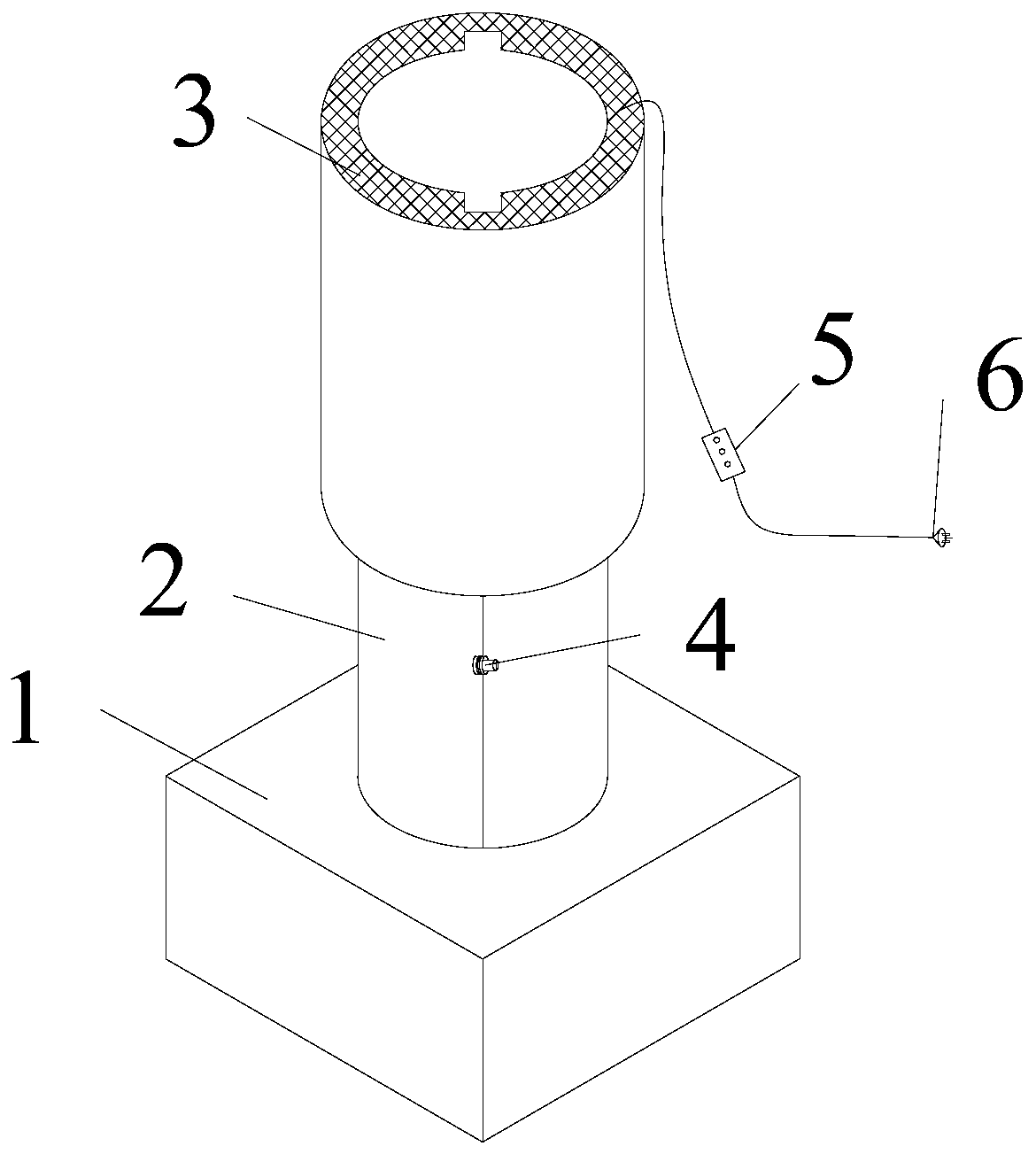

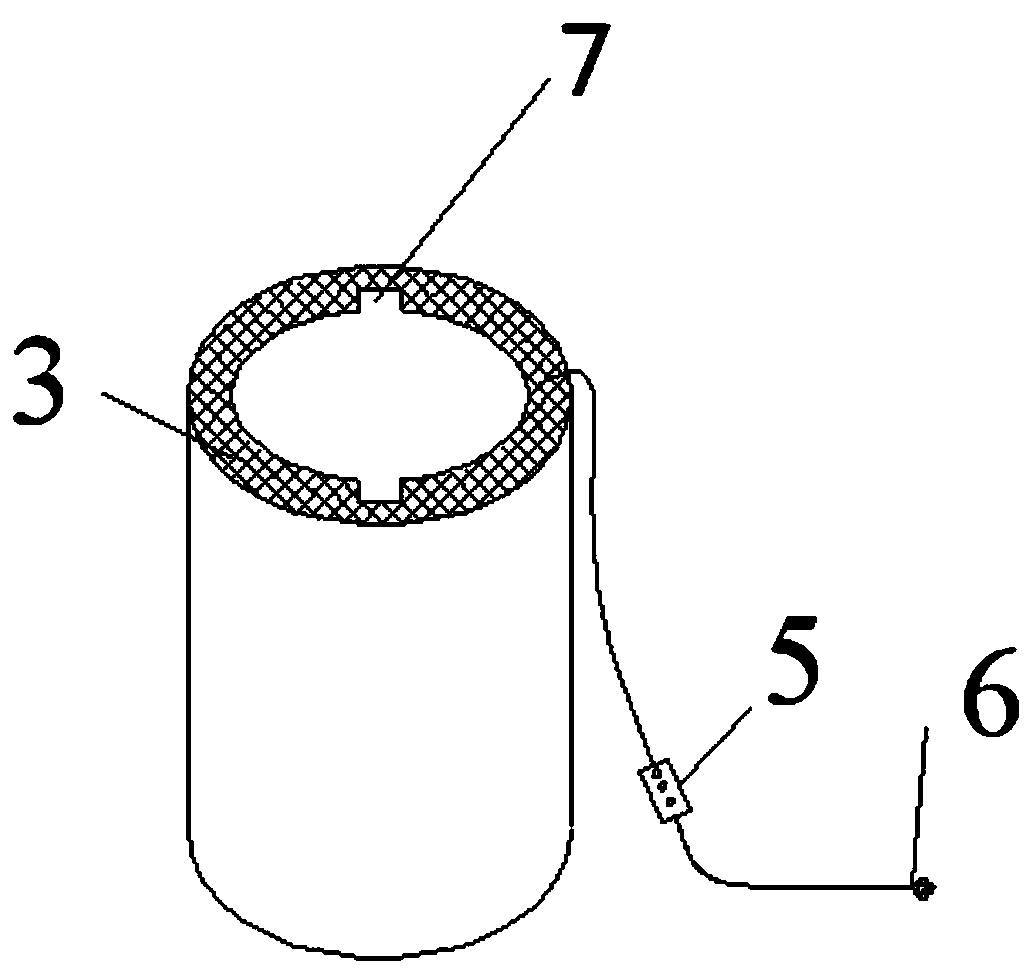

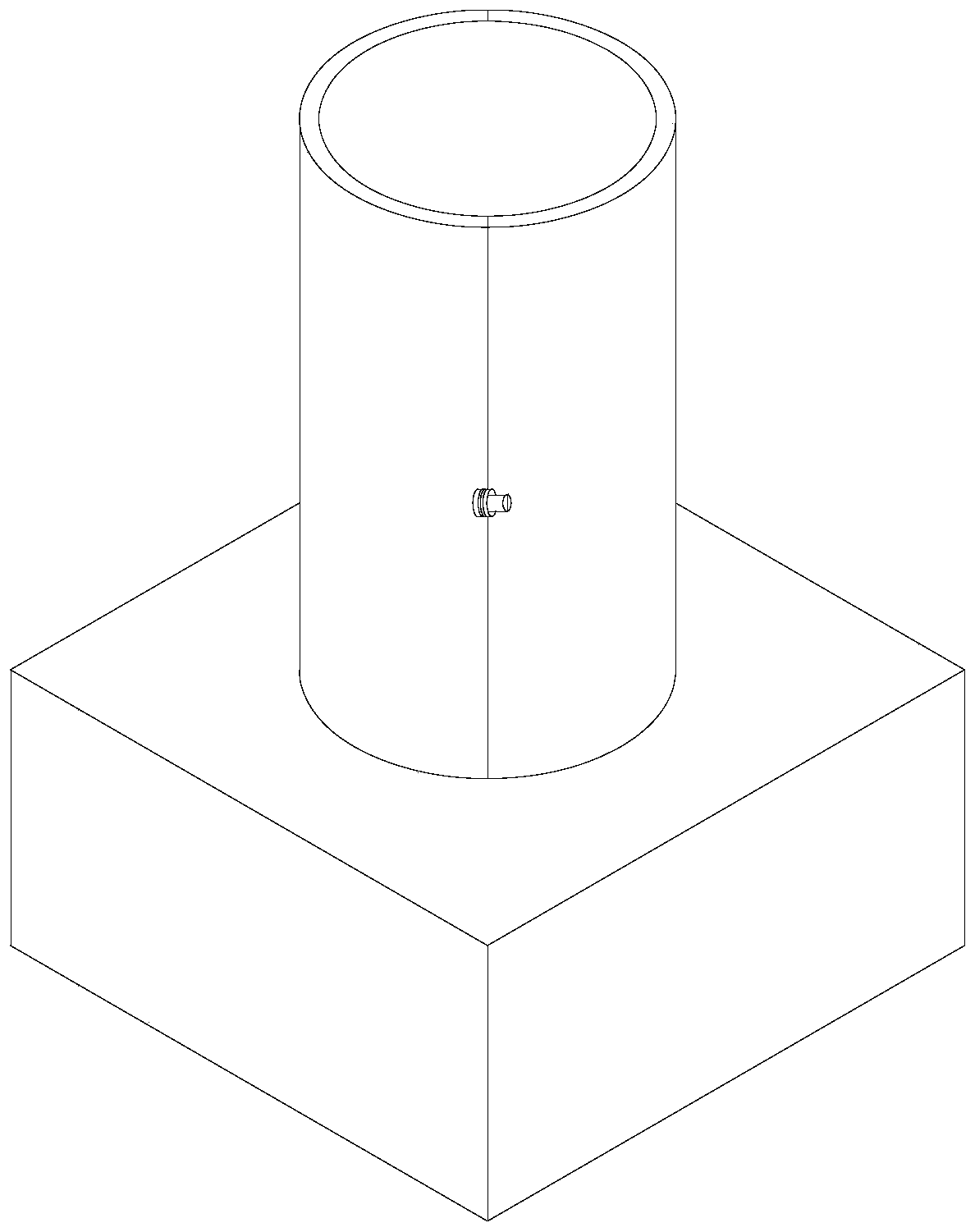

[0031] like figure 1 and image 3 The shown rapid prototyping equipment for a test piece of a standard similar material includes a forming base 1 and a forming die 2 arranged on the base 1. The forming model is confirmed according to the shape and size of the test piece to be formed. In this embodiment, The forming mold is a cylindrical mold, specifically, the cylindrical mold is made of such as Figure 4 The two half-cylindrical shells shown are snapped together, and the two half-cylindrical shells are fixedly connected by nuts 4, the two half-cylindrical shells are identical two half-cylindrical shells, and the inner surface of each half-cylindrical shell The surface is smooth and easy to demould. Nuts are fixed on the side edges of each semi-cylindrical shell. After fastening the two semi-cylindrical shells, the nuts on the two semi-cylindrical shells are in direct contact, and then the connecting bolts are inserted into the Connect the two semi-cylindrical shells to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com