Variable refrigerant volume system, anti-liquid-impact control method and device and readable storage medium

A multi-connection system and control method technology, applied in pump control, refrigerator, refrigeration components, etc., can solve problems such as compressor damage, cylinder damage, and liquid slamming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

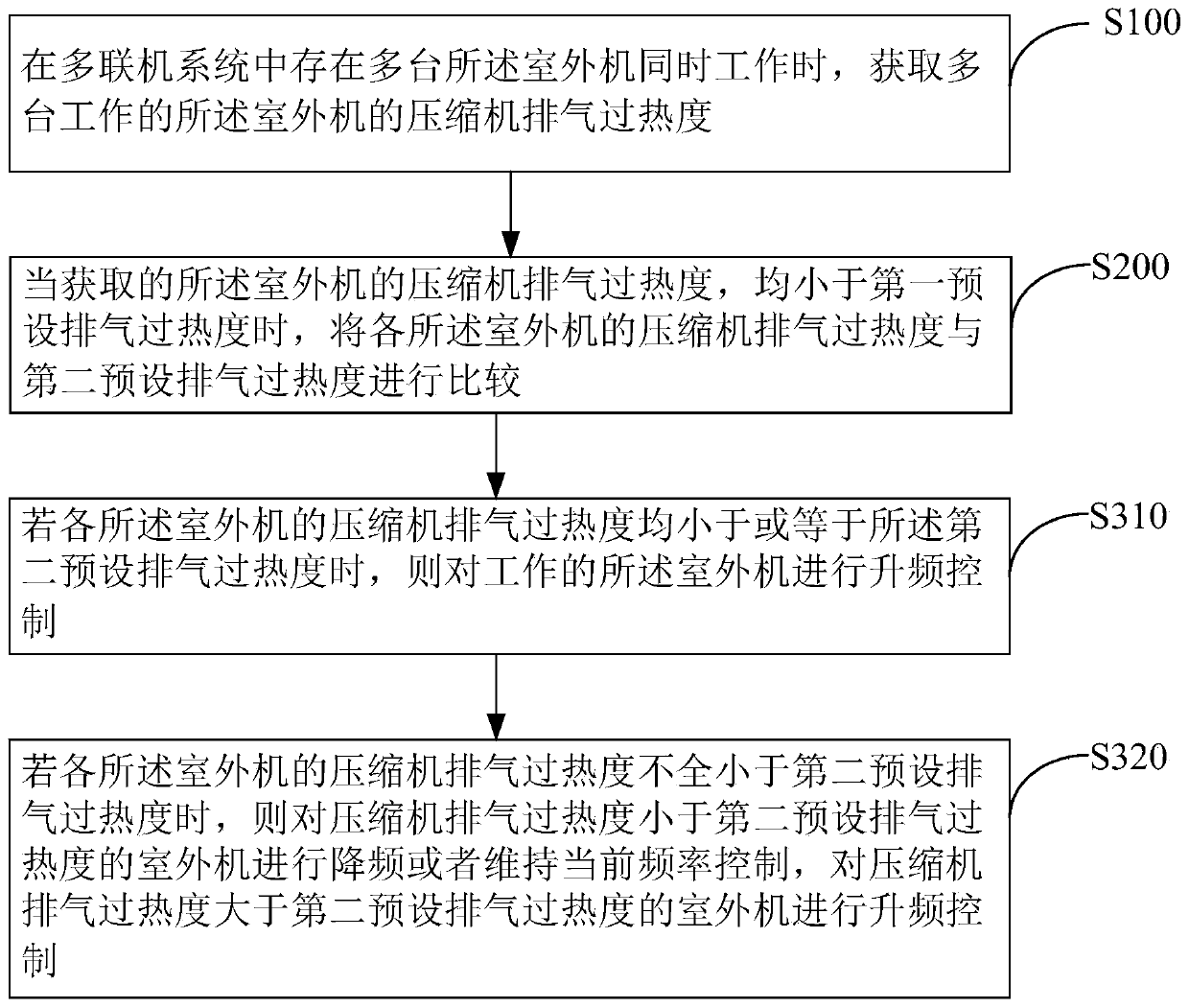

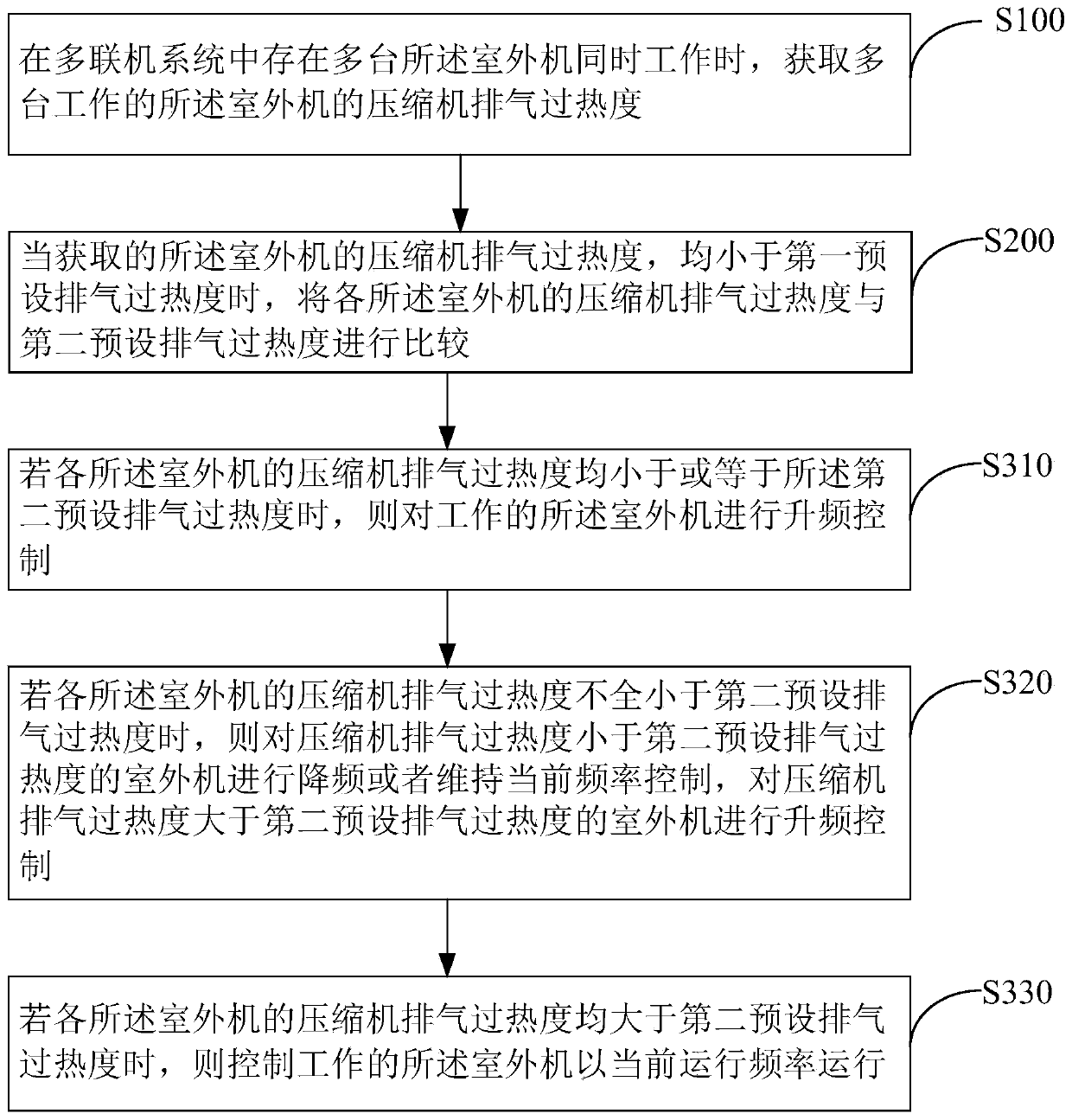

[0037] The present invention compares the exhaust superheat of each compressor with the preset exhaust superheat, and adjusts the operating frequency of each outdoor compressor according to different comparison results, so as to reduce the risk of compressor liquid shock and improve the performance of the compressor. Performance and reliability, to ensure that the superheat of the compressor exhaust of each outdoor unit remains normal, thereby preventing the occurrence of compressor liquid hammer.

[0038] In order to better understand the above-mentioned technical solutions, exemplary embodiments of the present disclosure will be described in more detail below with reference to the accompanying drawings. Although exemplary embodiments of the present disclosure are shown in the drawings, it should be understood that the present disclosure may be embodied in various forms and should not be limited to the embodiments set forth herein. Rather, these embodiments are provided for m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com