Muffler for an exhaust system of an internal combustion engine

一种排气系统、消音器的技术,应用在消音装置、排气装置、机器/发动机等方向,能够解决难排气系统恒定良好质量、排气系统干扰噪音发生很大变化等问题,达到避免干扰的哨音噪音、避免哨音噪音、容易制造的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

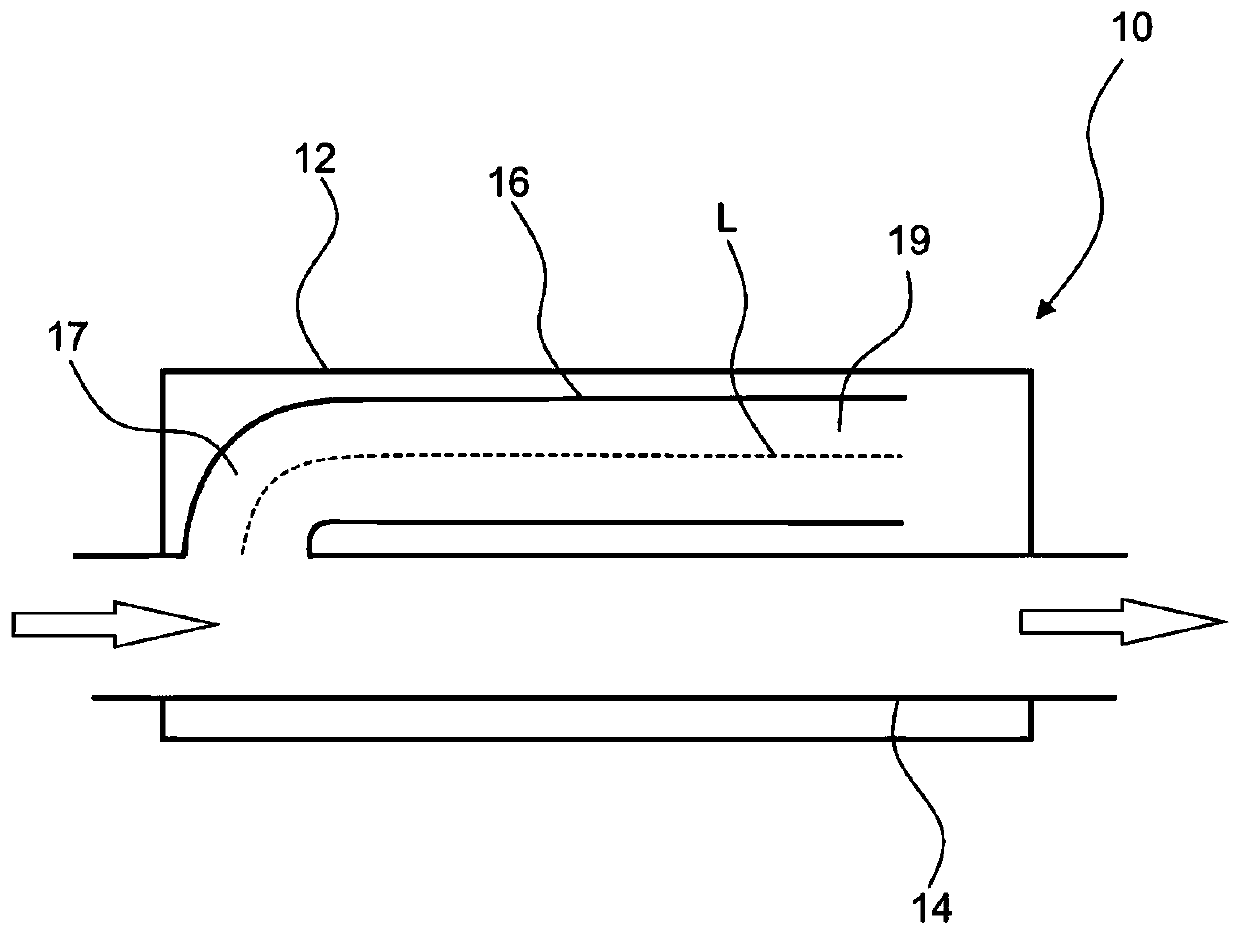

[0043] Figure 1a A longitudinal cross-sectional view of an exemplary muffler 10 is schematically shown. The basic structure and operating principles of the muffler 10 will be discussed in Figure 1a explained on the basis of

[0044] The muffler 10 is suitable for use in an exhaust system of an internal combustion engine, in particular an exhaust system of an internal combustion engine for a motor vehicle. The muffler 10 includes a housing 12 having a through-pipe 14 which conducts exhaust gas during operation of the muffler 10 and which is directed through the housing 12 through which the exhaust gas flows in the direction of the arrow. Through pipe 14.

[0045] A branch pipe 16 branches fluidly within the housing 12 . The branch pipe 16 is arranged within the housing such that its upstream end starts from the through pipe 14 and its downstream end ends freely and is open at the terminating end face. The length L of the branch pipe 16 is measured from the upstream end to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com