Method for preparing smooth and dense silver-coated copper powder by chemical plating method

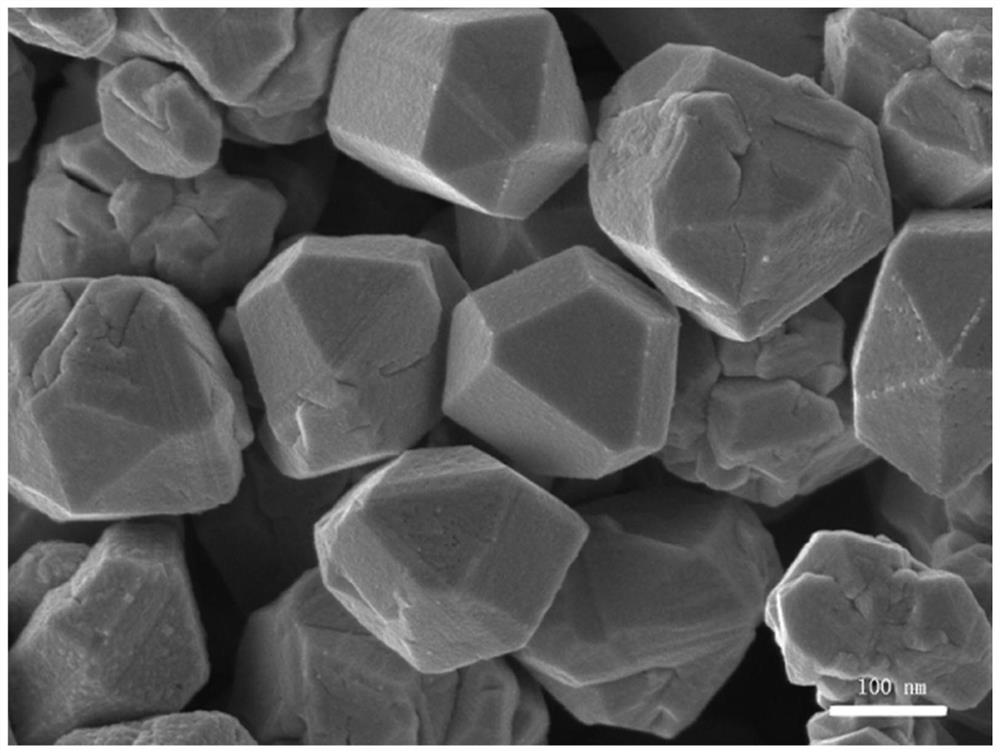

A technology of silver-coated copper powder and electroless plating, which is applied in liquid chemical plating, transportation and packaging, and metal processing equipment, etc. It can solve the problems of insufficient smoothness of the silver powder coating layer and large particle size of nano-powder, and achieve easy large-scale Production, reduction of specific surface area, good product dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A method for preparing smooth and dense silver-clad copper powder by electroless plating, adopts the following steps:

[0035] (1) Take 15g of copper powder with an average particle size of about 100nm, add it to 2g / L sodium hydroxide solution, remove surface organic matter, and then wash the copper powder with deionized water until neutral. Add the above-mentioned copper powder into 300 ml of deionized water, and then add 5.2 g of dispersant to the above-mentioned deionized water, and ultrasonically disperse to form a copper nano-powder suspension. The dispersant that can be selected is one or more of gum arabic, gelatin, isinglass or polypeptide, and the dispersant selected in this embodiment is gum arabic.

[0036] (2) Get 11.4g silver nitrate and join in 300ml aqueous solution, add complexing agent in above-mentioned solution, prepare silver complexing solution, the complexing agent that can select for use is thiourea, thiosemicarbazide, sodium thiosulfate, ammoniac...

Embodiment 2

[0039] A method for preparing smooth and dense silver-clad copper powder by electroless plating, adopts the following steps:

[0040] (1) Take 15g of copper powder with an average particle size of about 100nm, add it to 2g / L sodium hydroxide solution, remove surface organic matter, and then wash the copper powder with deionized water until neutral. Add the above-mentioned copper powder into 1500ml deionized water, then add 20g of polyvinyl alcohol into the above-mentioned deionized water, and ultrasonically disperse to form a copper nano powder suspension.

[0041] (2) Add 7.4g of silver nitrate to 1200ml of aqueous solution, add ammonia and EDTA to the above solution to prepare a silver complex solution, and the molar mass ratio of complexing agent to silver nitrate is 1:1.

[0042] (3) Mix the above solutions, then add 150ml of glucose solution and 300ml of nano-silver suspension in sequence, the molar ratio of reducing agent to silver complex is 1:1; the concentration of na...

Embodiment 3

[0044] A method for preparing smooth and dense silver-clad copper powder by electroless plating, adopts the following steps:

[0045] (1) Take 15g of copper powder with an average particle size of about 100nm, add it to 2g / L sodium hydroxide solution, remove surface organic matter, and then wash the copper powder with deionized water until neutral. Add the above-mentioned copper powder to 3000ml deionized water, then add 25g of polyvinyl alcohol and 10g of gelatin to the above-mentioned deionized water, and ultrasonically disperse to form a copper nano powder suspension.

[0046] (2) Add 0.3g of silver nitrate to 2000ml of aqueous solution, add sodium thiosulfate to the above solution to prepare a silver complex solution, the molar mass ratio of complexing agent to silver nitrate is 2:1.

[0047] (3) Mix the above solutions, then add 150ml ascorbic acid and formaldehyde solution and 300ml nano-silver suspension in sequence, the molar ratio of reducing agent to silver complex i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com