Method for weakening machine tool chatter and machine tool structure

A machine tool and flutter technology, which is applied in the field of machine tool vibration and control, can solve problems such as the limited ability of the machine bed to absorb vibration, and achieve the effect of weakening adverse effects and weakening machine tool chatter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0082] A method for weakening chatter of a machine tool, comprising the steps of:

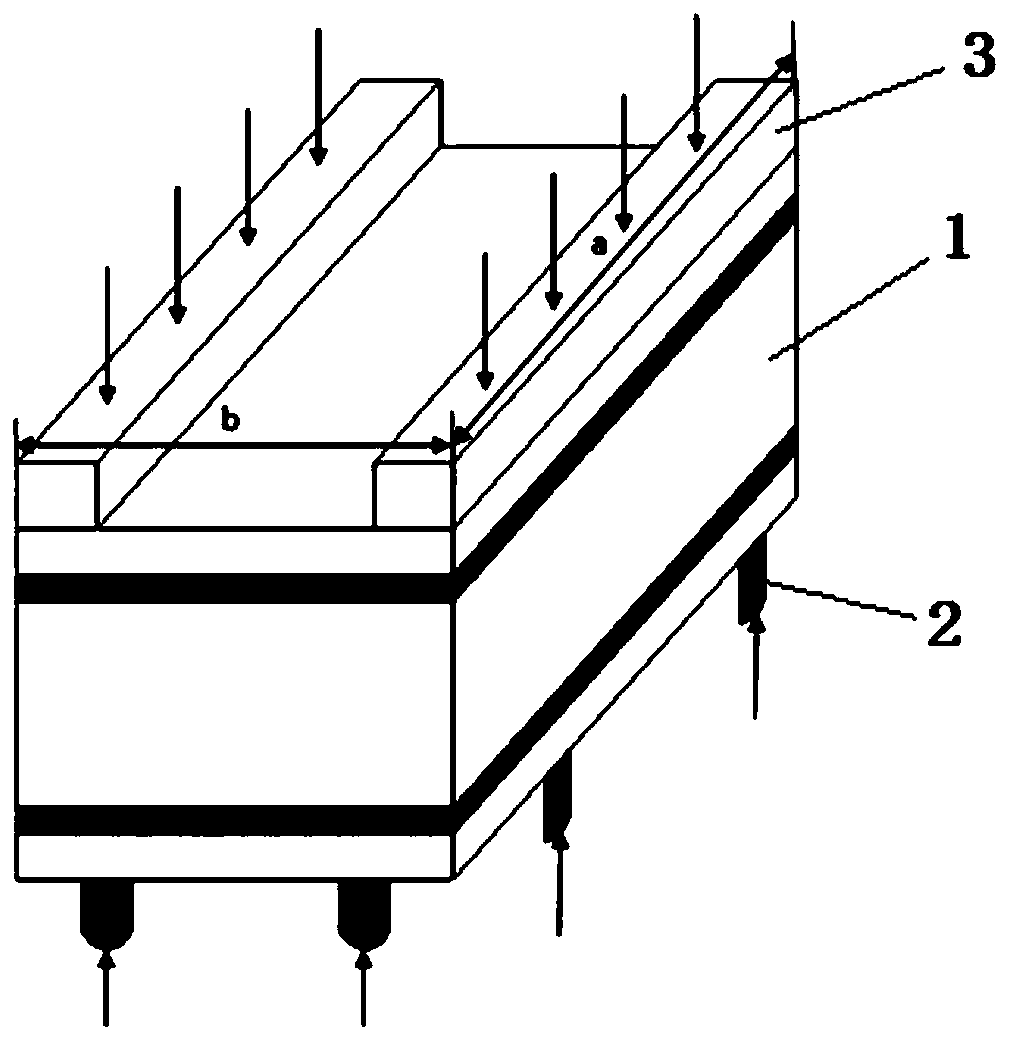

[0083] Step 1: According to the way of energy transmission during the flutter of the machine tool, determine the way the machine tool is implanted with viscoelastic damping material.

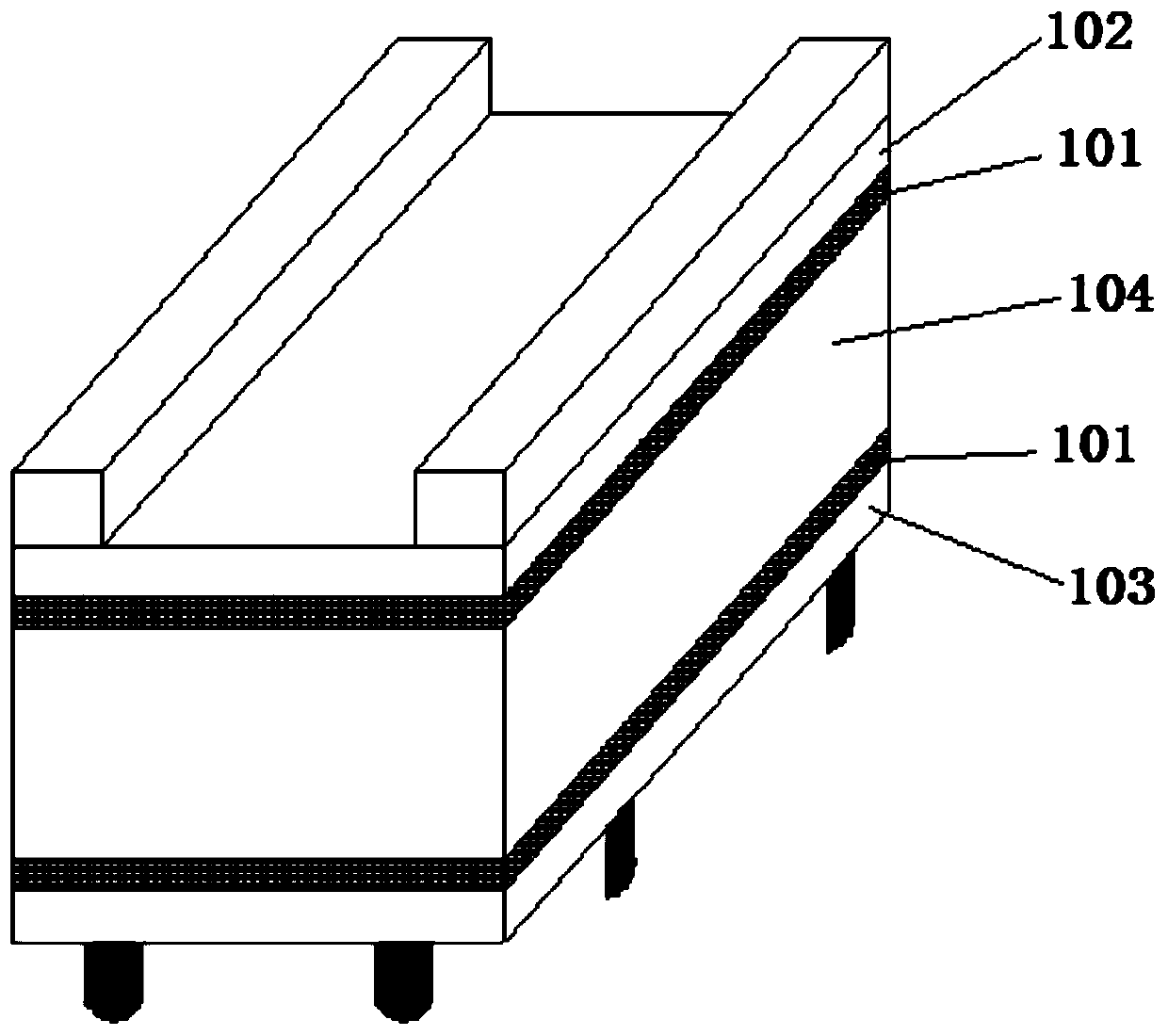

[0084] Step 2: Artificial marble can be used as the bed of the machine tool for implanting the viscoelastic damping material in the machine tool, so that the line rails and threaded holes can also be pre-embedded conveniently.

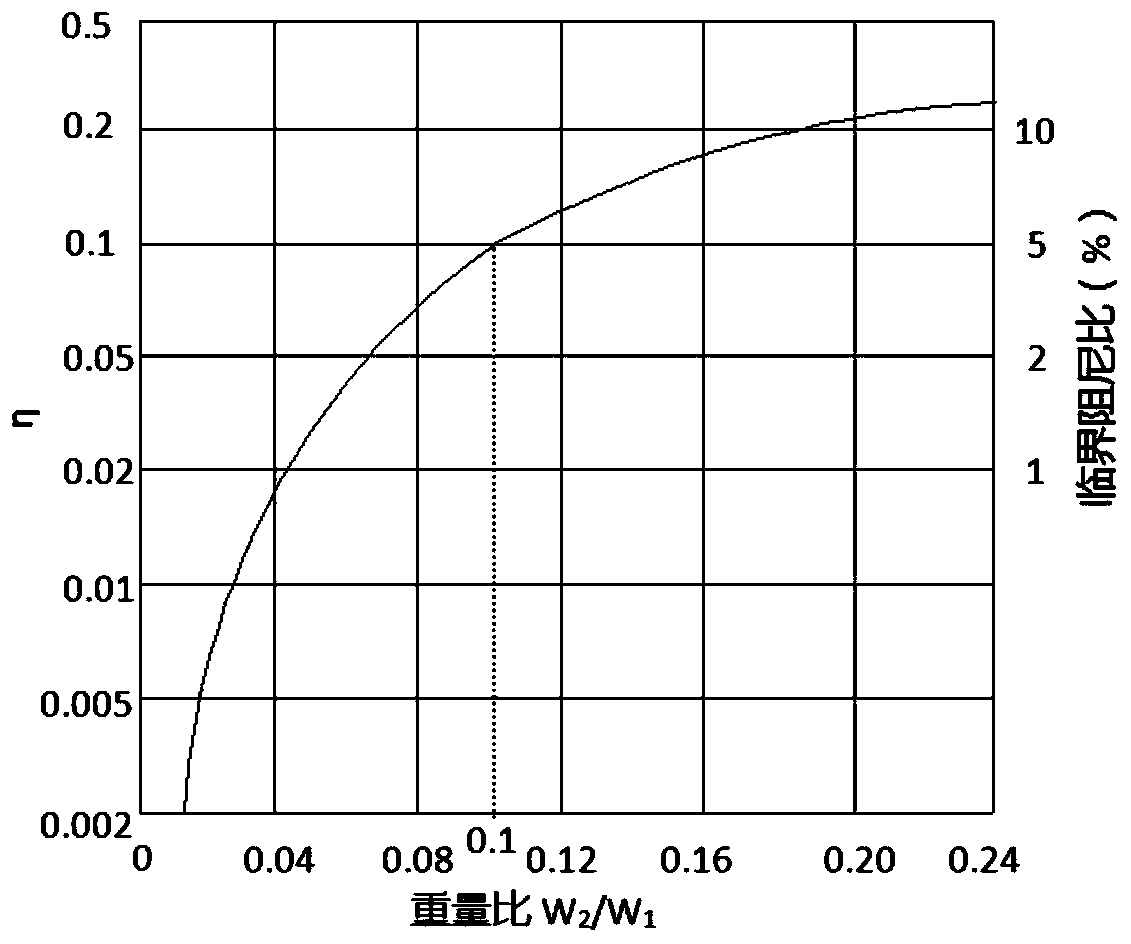

[0085] Step 3: The thickness of the implanted viscoelastic damping material is determined according to the size of the machine tool, and the Poisson's ratio and elastic modulus ratio of the artificial marble bed and the viscoelastic damping material are selected according to the genetic algorithm, and then the loss factor is determined to be maximized . By weight ratio and loss factor diagram, such as image 3 As shown, its specific calculation is as h / d=0.05ρ 1 / ρ 2 Determine the thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com