Deep-cavity screw locking device

A locking device and screw technology, which is applied in the field of screw locking, can solve the problems such as the screw fastening process meets the requirements, fails to meet the mass production requirements, poor quality consistency, etc., and realizes screw assembly automation, reduces interference, and increases positioning effect of means

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The above and other technical features and advantages of the present invention will be described in more detail below in conjunction with the accompanying drawings.

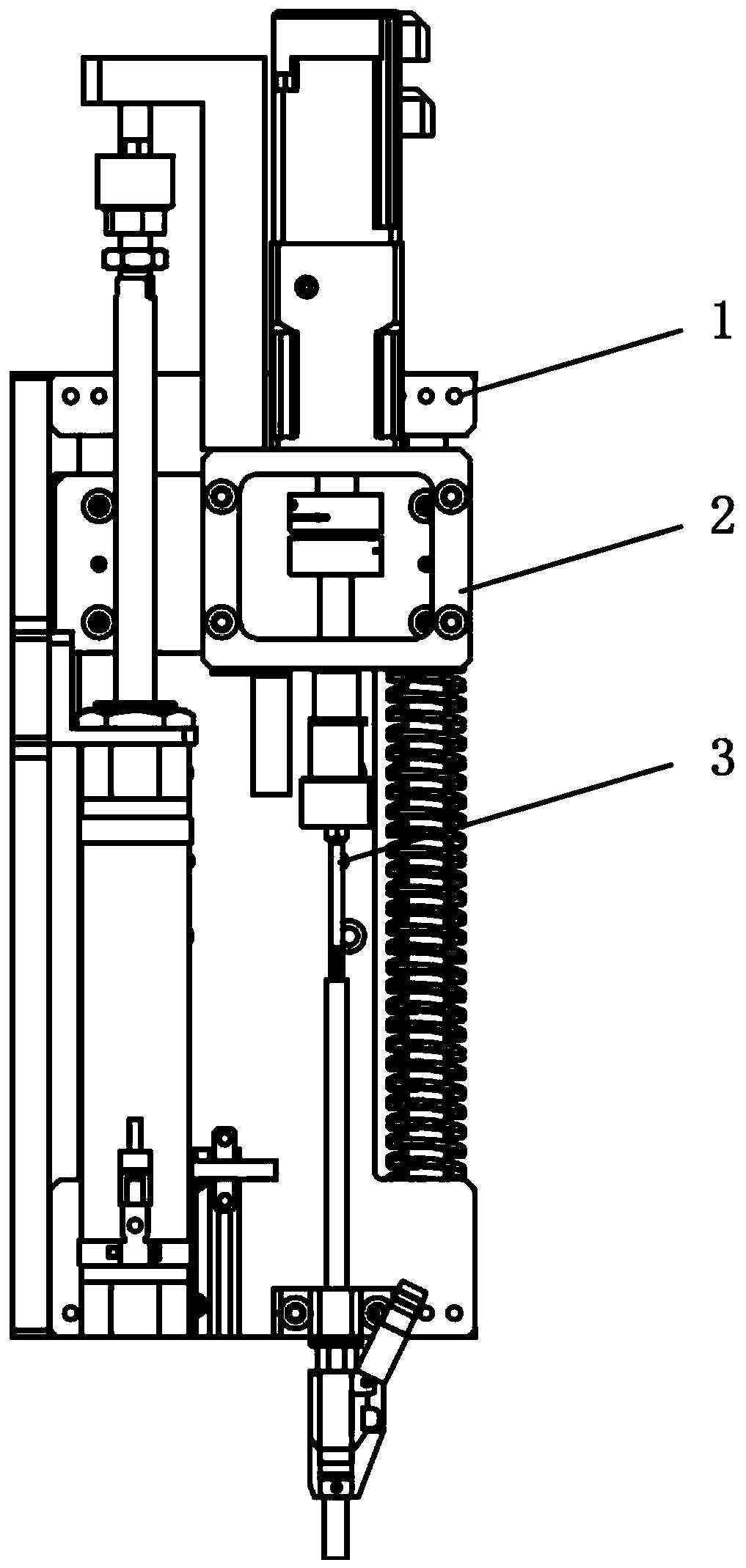

[0023] Such as figure 1 as shown, figure 1 It is a structural view of the deep cavity screw locking device; the deep cavity screw locking device includes a main movement assembly 1, a locking assembly 2 and a support assembly 3, and the main movement assembly 1 is arranged on the support assembly 3 , the main movement assembly 1 is connected to the locking assembly 2, and the main movement assembly 1 drives the locking assembly 2 to achieve linear displacement, thereby ensuring that the locking components on the locking assembly 2 move to a deep The specified position of the cavity, the locking assembly 2 realizes the rotation and locking operation of the screw.

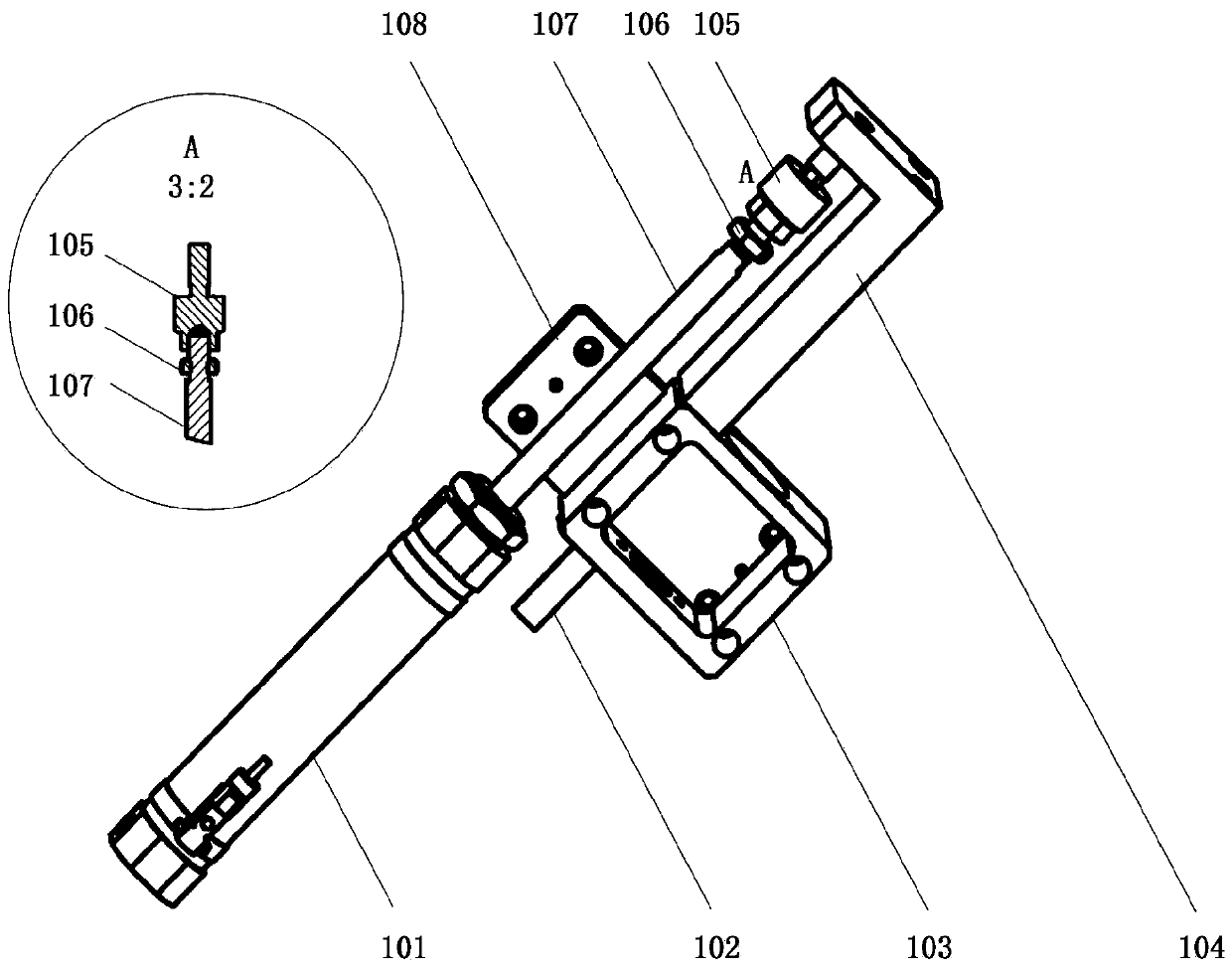

[0024] Such as figure 2 as shown, figure 2 It is a structural view of the main motion assembly; the main motion assembly 1 includes a cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com