Natural gas station yard analysis cabin on-line analysis instrument installation interval design method

An analytical instrument and natural gas station technology, applied in the field of online analysis technology and safety assurance of natural gas stations, can solve problems such as difficulty in obtaining installation spacing, failure to meet actual application requirements, lack of layout requirements for online analysis instruments in analysis cabins, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

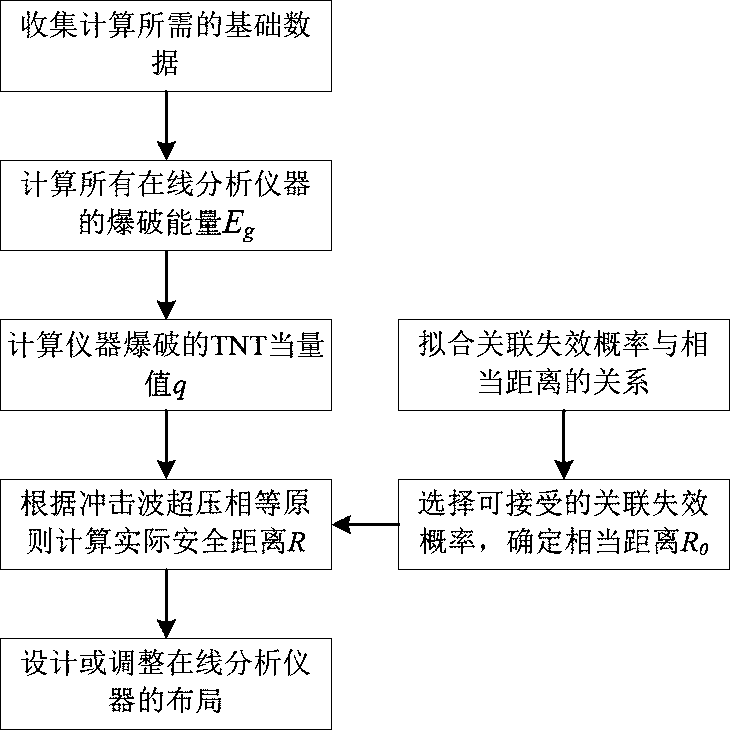

Method used

Image

Examples

Embodiment 1

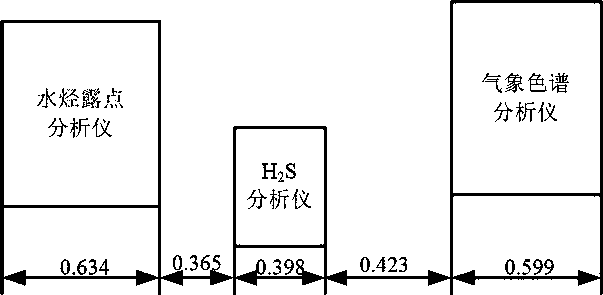

[0034] A water hydrocarbon dew point analyzer, H 2 One S analyzer and one gas chromatograph analyzer, the wall layout of the analyzer is as follows image 3 shown. It is recommended that when the associated failure probability is controlled below 20%, the design of the installation spacing of online analytical instruments should be completed. (take water hydrocarbon dew point analyzer sample gas k=1.25, H 2 S analyzer sample gas k=1.29, gas chromatograph sample gas k=1.38) step (A) collects water hydrocarbon dew point analyzer, H 2 The volume of S analyzer and gas chromatograph analyzer is 0.214m 3 、0.038m 3 with 0.208m 3 , the working pressure is 2.7MPa, 0.56MPa and 0.7MPa in turn, and the actual distance between the instruments is determined by image 3 known;

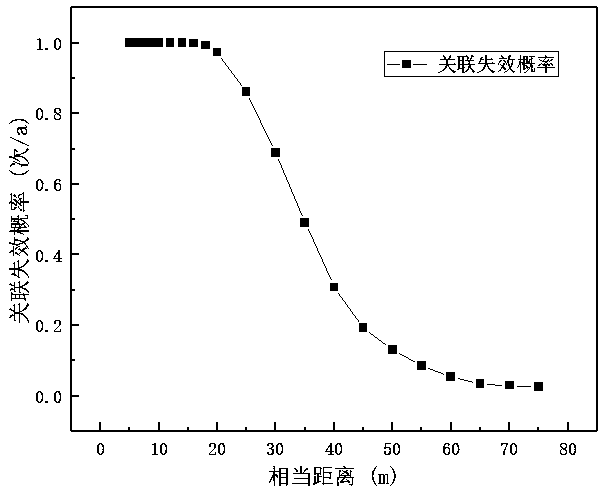

[0035] Step (B) calculates the blasting energy of each instrument according to the basic data and converts it into a TNT equivalent value, and then determines 3-1=2 analytical instruments with higher TNT equiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com