Reliability index evaluation method of electronic control system of instrument

An electronic control system and reliability technology, applied in the general control system, control/regulation system, environment/reliability test, etc., can solve problems such as time-consuming cost, affecting the progress of research and development, missing product reliability improvement, etc., to achieve The effect of shortening the test time, shortening the test cycle and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

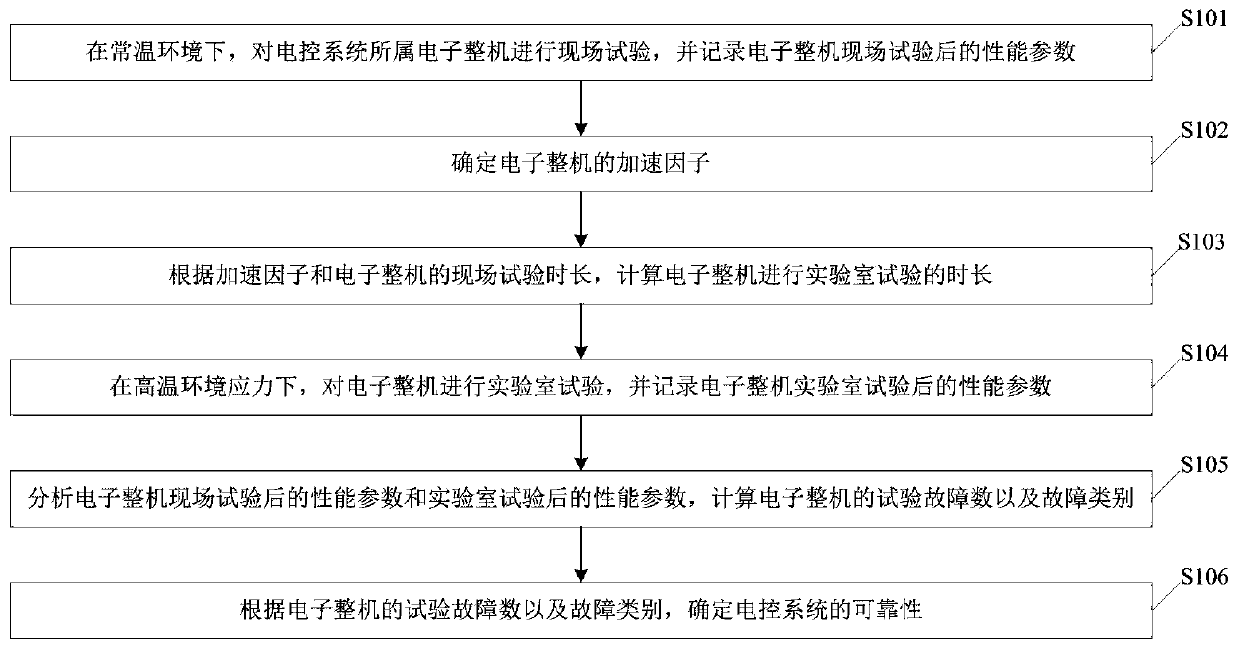

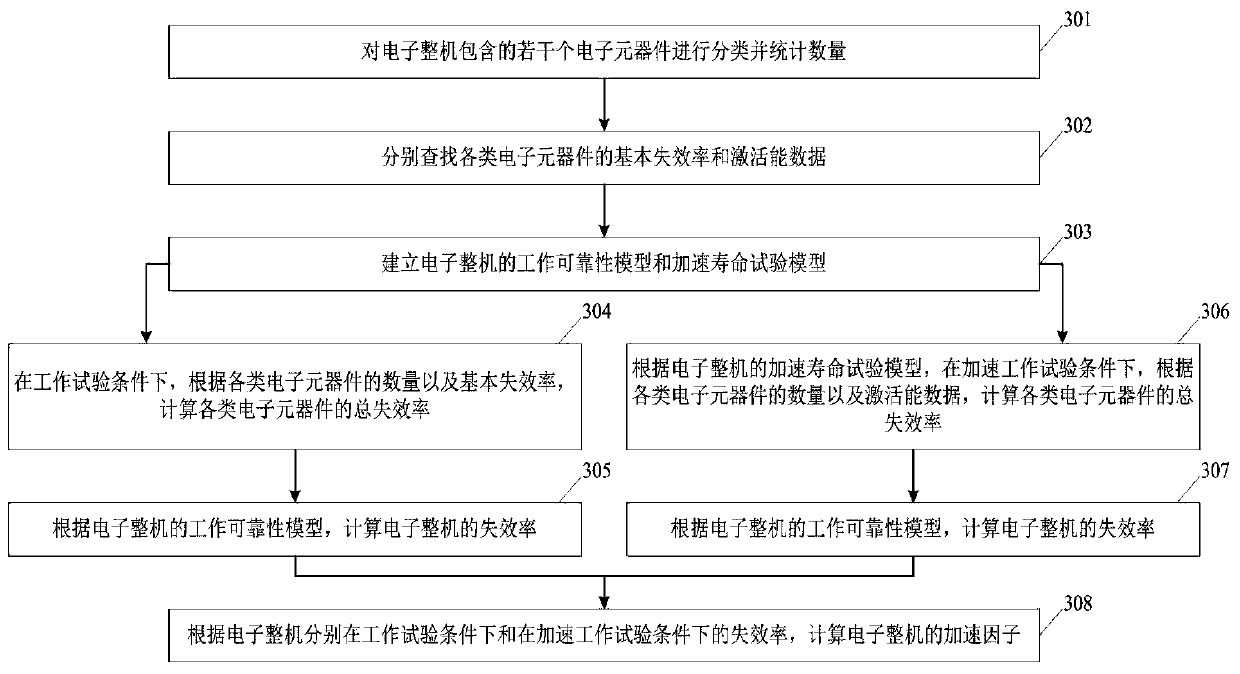

Method used

Image

Examples

Embodiment 1

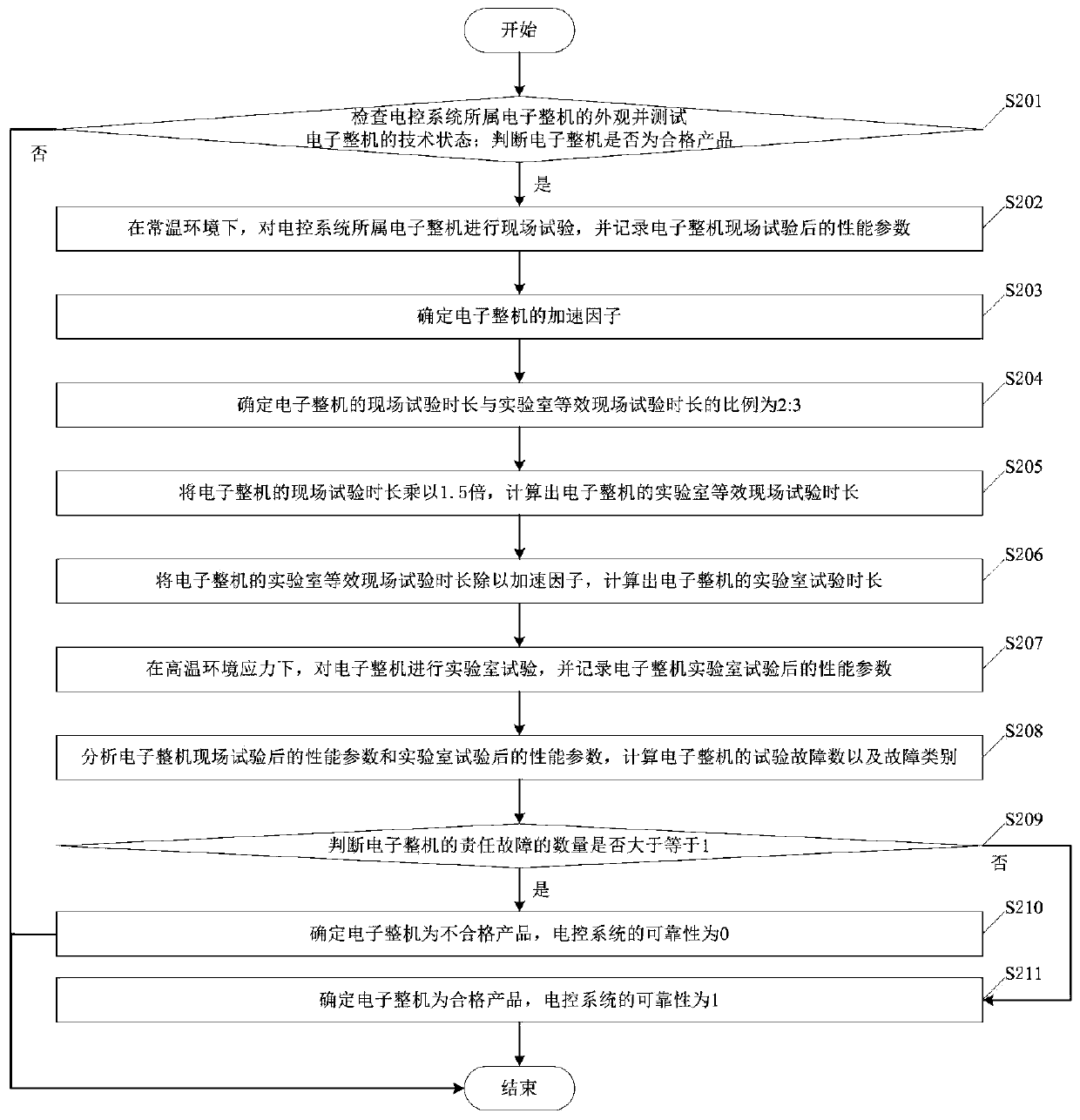

[0056] This embodiment provides another reliability index assessment method for the electronic control system of the instrument, such as figure 2 as shown, figure 2 It is a flow chart of another reliability index assessment method of an instrument electronic control system according to Embodiment 1 of the present invention, including the following steps:

[0057] Step S201: Check the appearance of the electronic complete machine belonging to the electronic control system and test the technical status of the electronic complete machine; judge whether the electronic complete machine is a qualified product; if yes, perform steps S202 to S209; if not, end this process;

[0058] In the embodiment of the present invention, the above-mentioned electronic complete machine can be a dual-frequency full-digital high-frequency ocean sounder, and the dual-frequency full-digital high-frequency ocean sounder is mainly composed of four parts: a receiver, a transmitter, a receiving antenna, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com