A kind of polymer emulsion building waterproof paint and preparation method thereof

A polymer emulsion and building waterproofing technology, applied in coatings and other directions, can solve problems such as inability to solve low-temperature construction, reaction principles, and design ideas that cannot be applied, and achieve excellent waterproofing effect, widen the scope of construction environment, and stable performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

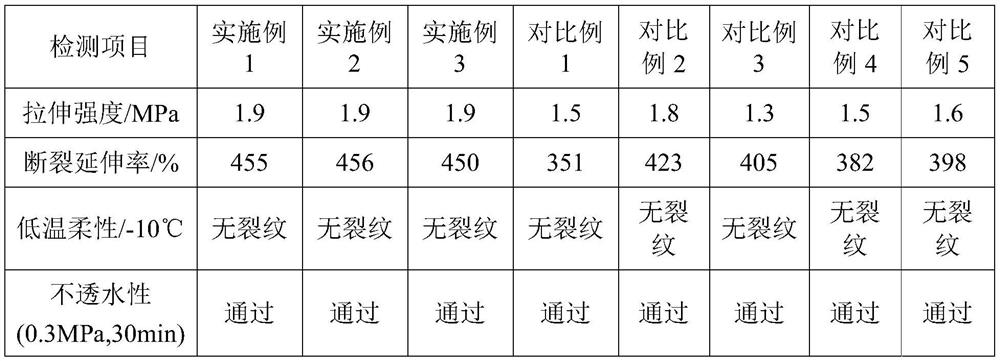

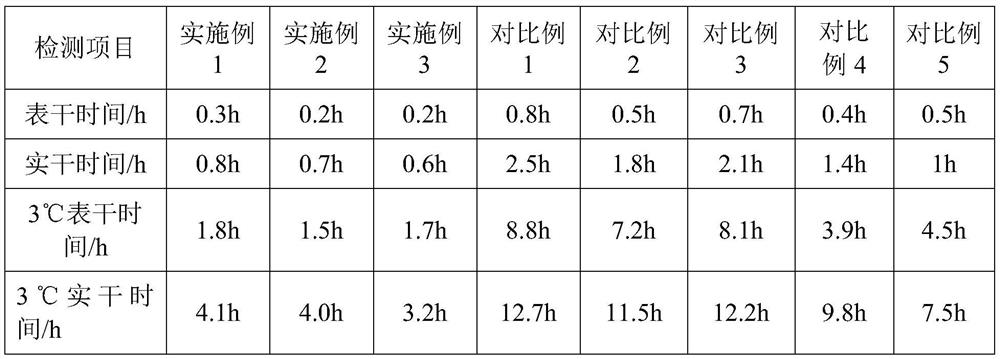

Examples

Embodiment 1

[0037] Measure 40 weights of deionized water into the liquid material mixing tank, turn on the disperser of the mixing tank, keep the speed at 200r / min, add 6 weights of dispersant, 8 weights of defoaming agent, and stir for 3 minutes. Add 480 weights of styrene-acrylic emulsion and 5 weights of flocculant in sequence, stir at 300r / min for 5 minutes, then slowly add 100 weights of mica powder, 350 weights of precipitated barium sulfate, and 20 weights of drying agent, and stir at 800r / min for 20 Minutes, and finally slowly add 2 weights of thickener and 2 weights of preservatives successively, and stir at 600r / min for 8 minutes. Reduce the rotational speed to 200r / min and stir for 4 minutes to obtain a polymer emulsion architectural waterproof coating after mechanical defoaming.

Embodiment 2

[0039] Measure 40 weights of deionized water into the liquid material mixing tank, turn on the disperser of the mixing tank, keep the speed at 200r / min, add 6 weights of dispersant, 8 weights of defoaming agent, and stir for 3 minutes. Add 480 weights of styrene-acrylic emulsion and 8 weights of flocculant in sequence, stir at 300r / min for 5 minutes, then slowly add 100 weights of mica powder, 350 weights of precipitated barium sulfate, and 20 weights of drying agent, and stir at 800r / min for 20 Minutes, and finally slowly add 2 weights of thickener and 2 weights of preservatives successively, and stir at 600r / min for 8 minutes. Reduce the rotational speed to 200r / min and stir for 4 minutes to obtain a polymer emulsion architectural waterproof coating after mechanical defoaming.

Embodiment 3

[0041] Measure 40 weights of deionized water into the liquid material mixing tank, turn on the disperser of the mixing tank, keep the speed at 200r / min, add 6 weights of dispersant, 8 weights of defoaming agent, and stir for 3 minutes. Add 480 weights of styrene-acrylic emulsion and 5 weights of flocculant in sequence, stir at 300r / min for 5 minutes, then slowly add 100 weights of mica powder, 350 weights of precipitated barium sulfate, and 25 weights of drying agent, and stir at 800r / min for 20 Minutes, and finally slowly add 2 weights of thickener and 2 weights of preservatives successively, and stir at 600r / min for 8 minutes. Reduce the rotational speed to 200r / min and stir for 4 minutes to obtain a polymer emulsion architectural waterproof coating after mechanical defoaming.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com