A cargo elevator and its loading and unloading method

A technology of elevators and electrical control devices, which is applied to elevators, hoisting devices, transportation and packaging in buildings, and can solve problems such as limiting the application of freight elevators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

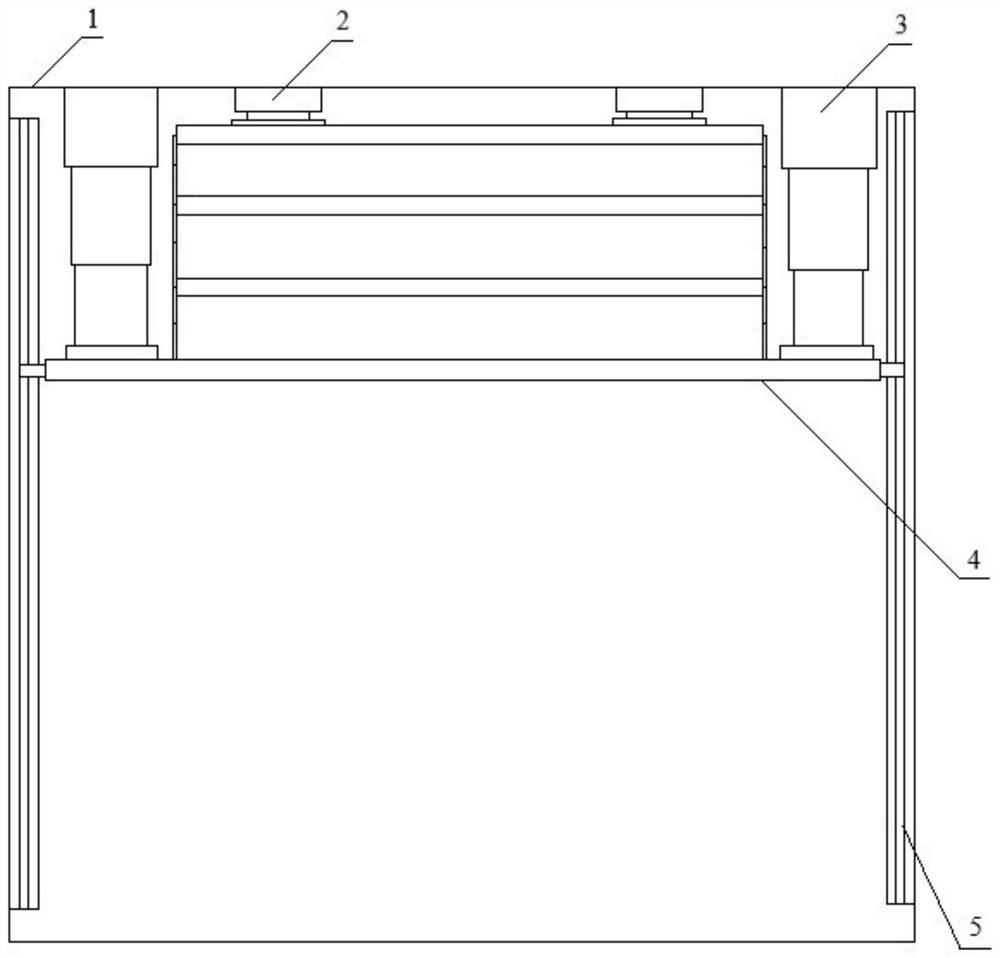

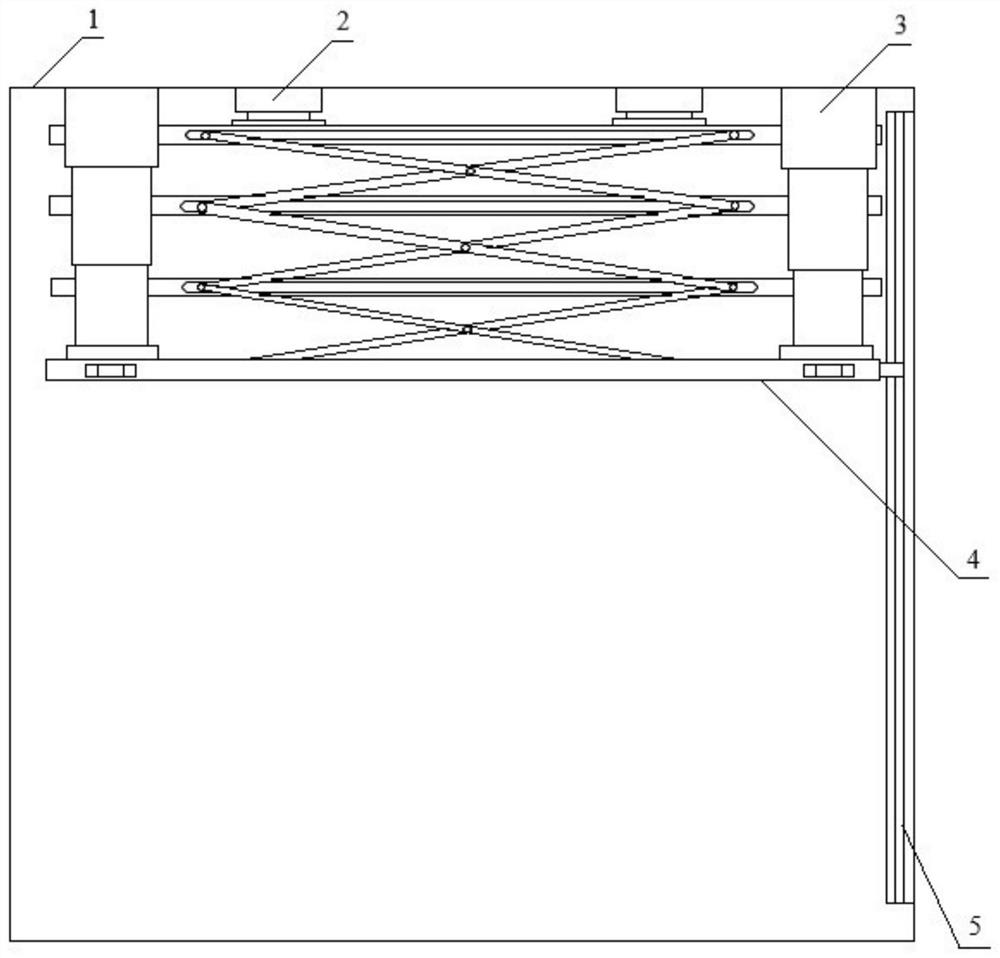

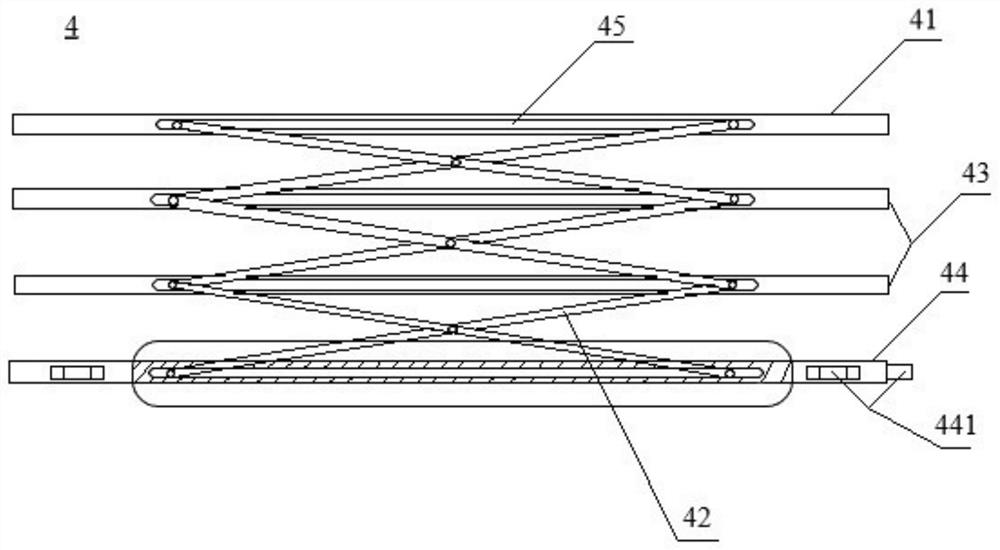

[0037] A freight elevator, comprising a car 1, an electrical control device (not shown), a first driving device 2, a second driving device 3, a vertical telescopic shelf 4, and a vertical guide rail 5, wherein the first driving device 2 and the second driving device The second driving device 3 is connected with the electric control device and installed on the top inner wall of the car 1, the vertical guide rail 5 is installed on the surrounding inner wall of the car 1, and the vertical telescopic shelf 4 is a multi-layer structure, which includes a top plate 41, a cross movable Rod 42 , several intermediate transmission boards 43 and bottom transmission board 44 , the top board 41 is connected with the first driving device 2 , and the bottom transmission board 44 is slidably connected to the vertical guide rail 5 and connected with the second driving device 3 .

[0038] The cross movable rod 42 is used for the connection between the adjacent two layers in the vertical telescopi...

Embodiment 2

[0046] The steps of loading and unloading goods by using the above freight elevator are as follows:

[0047] Step 1. On the starting floor, according to the position of the input board outside the car and the height of the goods, the first drive device and the second drive device are controlled by the electric control device to lower the bottom transmission plate and the top plate, and the bottom transmission plate is lowered. The stroke is greater than the top plate, so as to stretch the vertical telescopic shelf until the distance between each layer of the vertical telescopic shelf is greater than the height of the goods, and the bottom transmission plate is flush with the input plate outside the car, and the pneumatic brake in the sliding groove of the bottom transmission plate is activated to connect the cross The movable rod and the pivot pin of the bottom transmission plate are fixed in the sliding groove, and then the goods are transported from the input plate outside th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com