Shell-shaped tooth appliance production method and system and terminal equipment

A technology for a dental appliance and a production method, which is applied in the field of orthodontic treatment, can solve the problems affecting the manufacturing process of the shell-shaped dental appliance, prone to recognition deviation, slow recognition speed, etc., so as to achieve recyclability, improve production efficiency, Achieve the effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

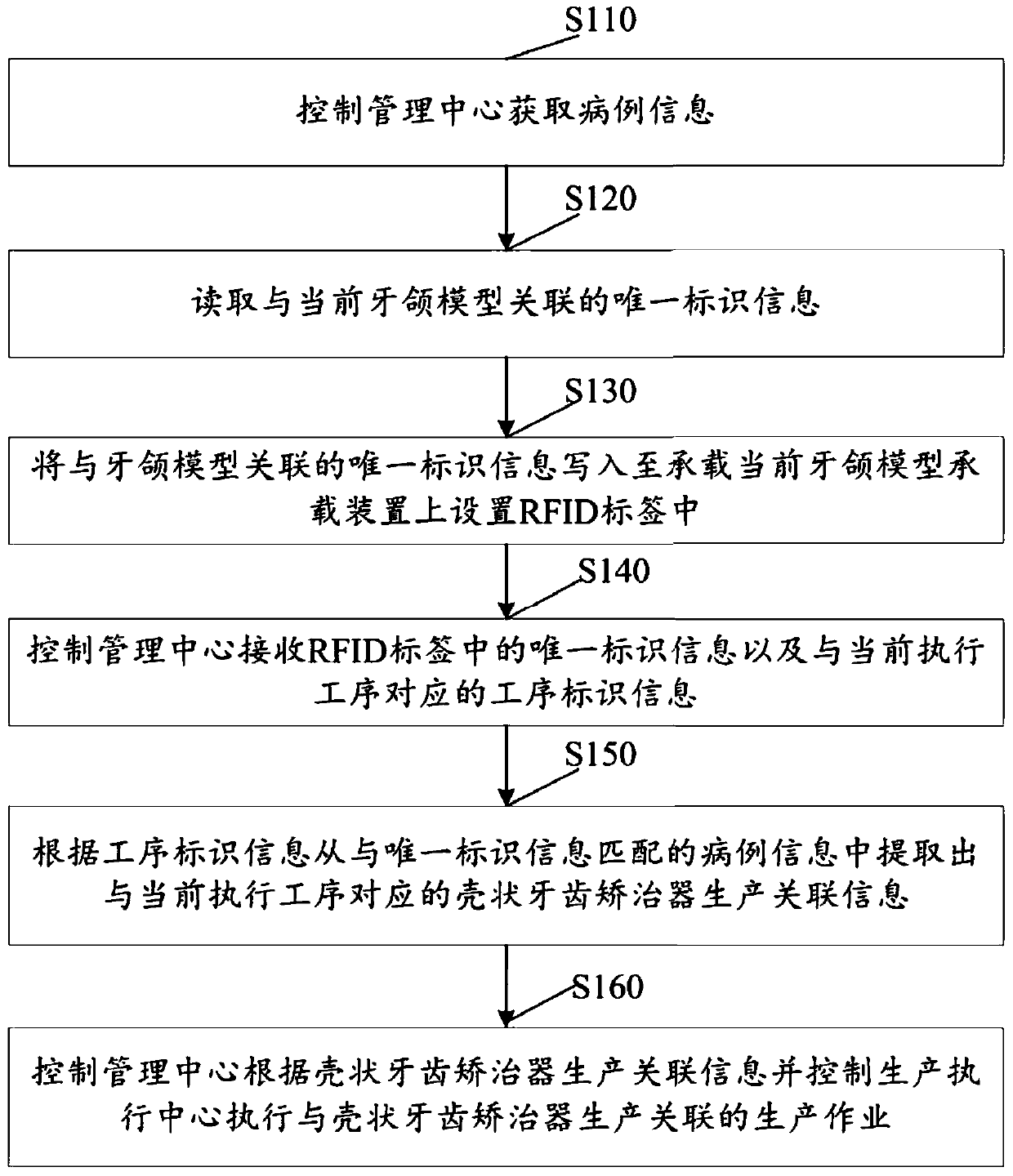

[0040] see figure 1 , which is a flow chart of a method for producing a shell-shaped dental appliance, specifically comprising:

[0041] S110: the control management center acquires case information;

[0042] S120: the control management center reads the unique identification information associated with the current jaw model through the production execution center;

[0043] S130: the control management center controls the production execution center to write the unique identification information associated with the current dental model into the RFID tag set on the carrying device carrying the current dental model;

[0044] S140: The control management center receives the unique identification information in the RFID tag read by the production execution center and the process identification information corresponding to the current execution process;

[0045] S150: The control management center extracts the production-related information of the shell-shaped dental appliance co...

Embodiment 2

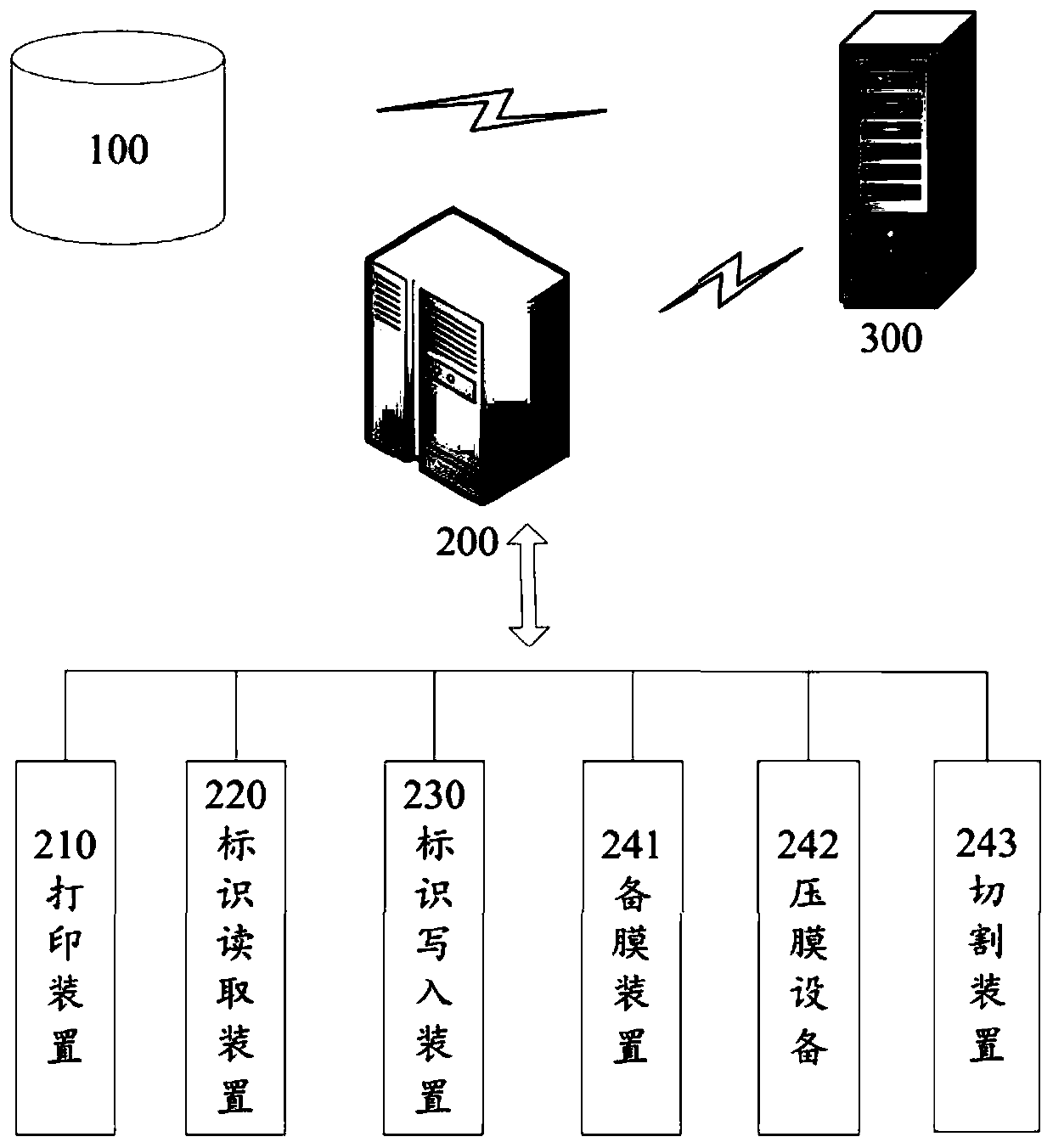

[0068] see figure 2 , a shell-shaped dental appliance production system according to the present invention, comprising: a control management center 100 , a production execution center 200 , an information identification device 220 , an information writing device 230 , a production process device, and a case database 300 .

[0069] The control management center 100 is configured to obtain case information and send the case information to the production execution center 220 . The control and management center 100 may include when obtaining case information: The first implementation mode is that the control management center 100 directly obtains case information from the case database 300 by connecting to the case database 300 when case information is needed. The second embodiment is that the control management center 100 regularly updates the case to the local storage unit, and directly stores the case information in the local storage unit. In addition, in an integrated circui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com