A device and method for measuring the overall error of gears based on double circular gratings

A technology of overall error and measuring device, which is applied in the direction of measuring device, optical device, mechanical component testing, etc., can solve the problems that cannot truly reflect the measured gear, affect the accuracy of the overall error measuring instrument of the gear, and achieve the goal of improving the measurement accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below in conjunction with accompanying drawing, present embodiment is described further:

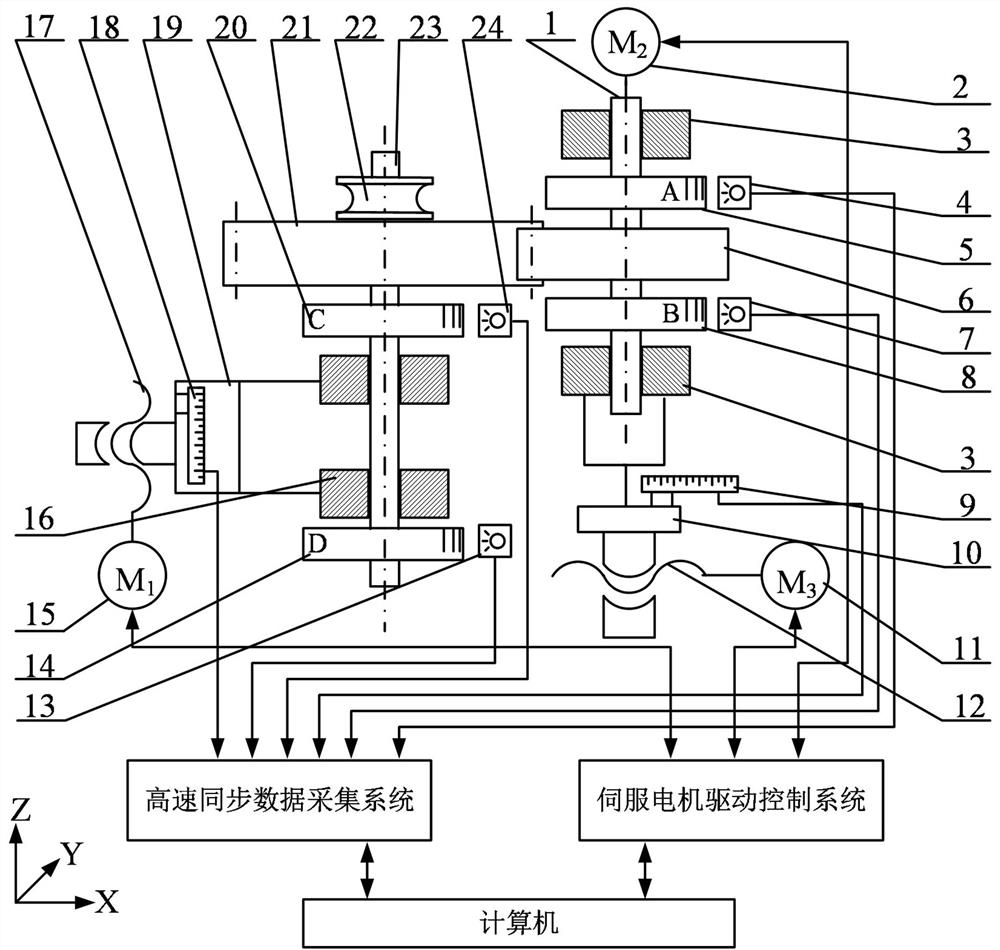

[0036] In this embodiment, a device for measuring the overall error of gears based on double circular gratings is designed, and the method of using the device for measurement is described.

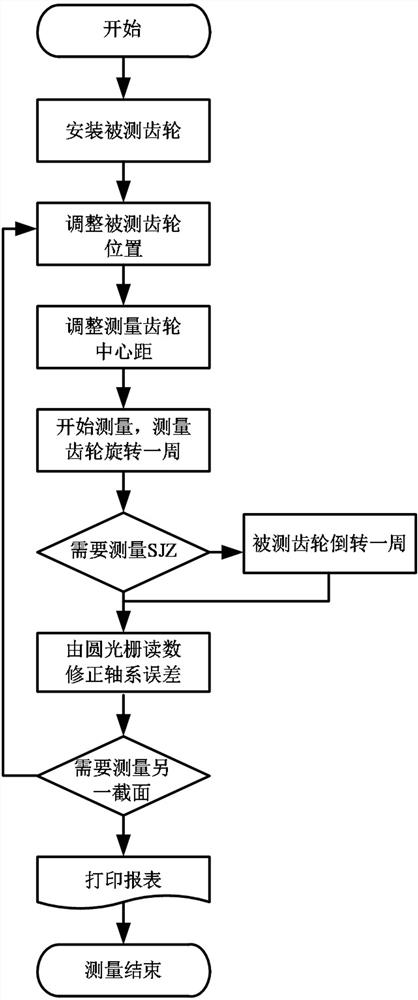

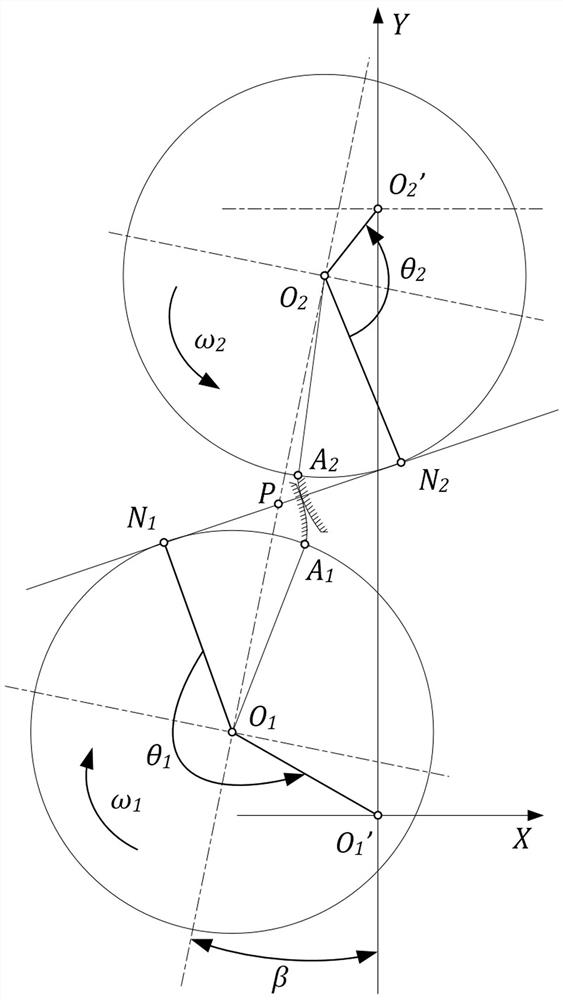

[0037] In this embodiment, the computer drives the servo motor to drive the measuring gear to realize the rolling scanning measurement of all the gear teeth of the tested gear, and the angular displacement signal generated by the measuring gear and the tested gear during the transmission process is converted into an electrical signal through a circular grating. The data is input into the computer through the data acquisition circuit, and the adverse effects of the shafting error on the measurement results are corrected by the circular grating readings. After analysis and calculation and data processing, the overall error and individual items of the gear under test can be obtained in accordance ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com