Vacuum system for the production of titanium sponge in a 7.5-ton i-type furnace

A vacuum system, titanium sponge technology, applied to machines/engines, mechanical equipment, pumps, etc., can solve the problem of pump oil contamination of titanium sponge, improve the quality of titanium sponge, prevent poor air tightness of pipelines, and prevent pump air The effect of reduced ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing.

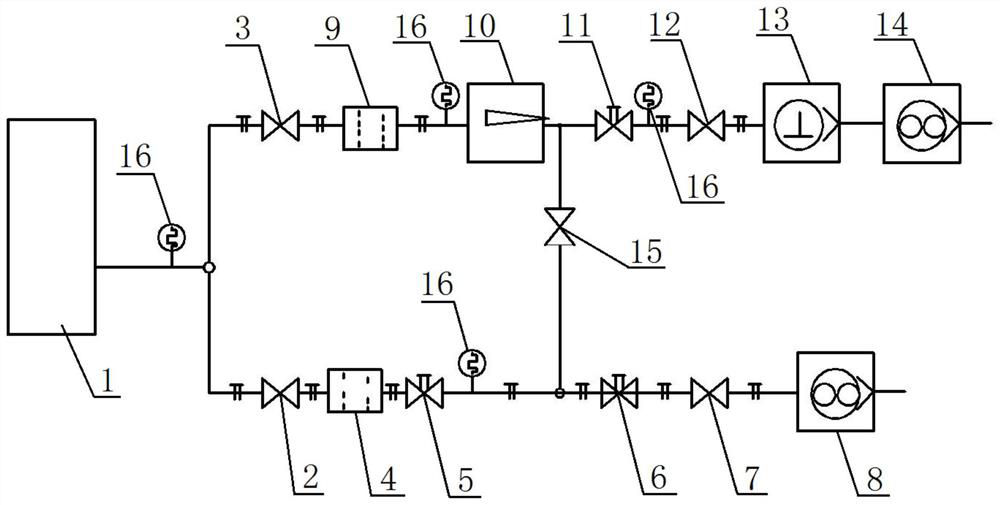

[0020] like figure 1 As shown, the vacuum system for the production of titanium sponge in a 7.5-ton I-type furnace of the present invention includes three low, medium and high vacuum pumping passages, and the components include a still 1, and the still 1 is connected to the first pneumatic baffle valve through a three-way connection. 2 and the second pneumatic flapper valve 3, the connection at this place is connected by a vacuum pipeline, the same below. A vacuum gauge 16 is also arranged between the distiller 1 and the tee.

[0021] The first pneumatic flapper valve 2 is connected to the first catcher 4, the first catcher 4 is connected to the first manual valve 5, the first manual valve 5 is connected to the second manual valve 6, and the second manual valve 6 is connected to The third pneumatic baffle valve 7 is connected to the first screw pump 8 . Wherein, a vacuum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com