Drilling damping equipment for automobile accessory machining

A technology for shock absorption equipment and auto parts, used in metal processing equipment, metal processing, maintenance and safety accessories, etc., can solve the problems of inconvenient cleaning of waste and the inability of drilling machines to achieve continuous drilling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

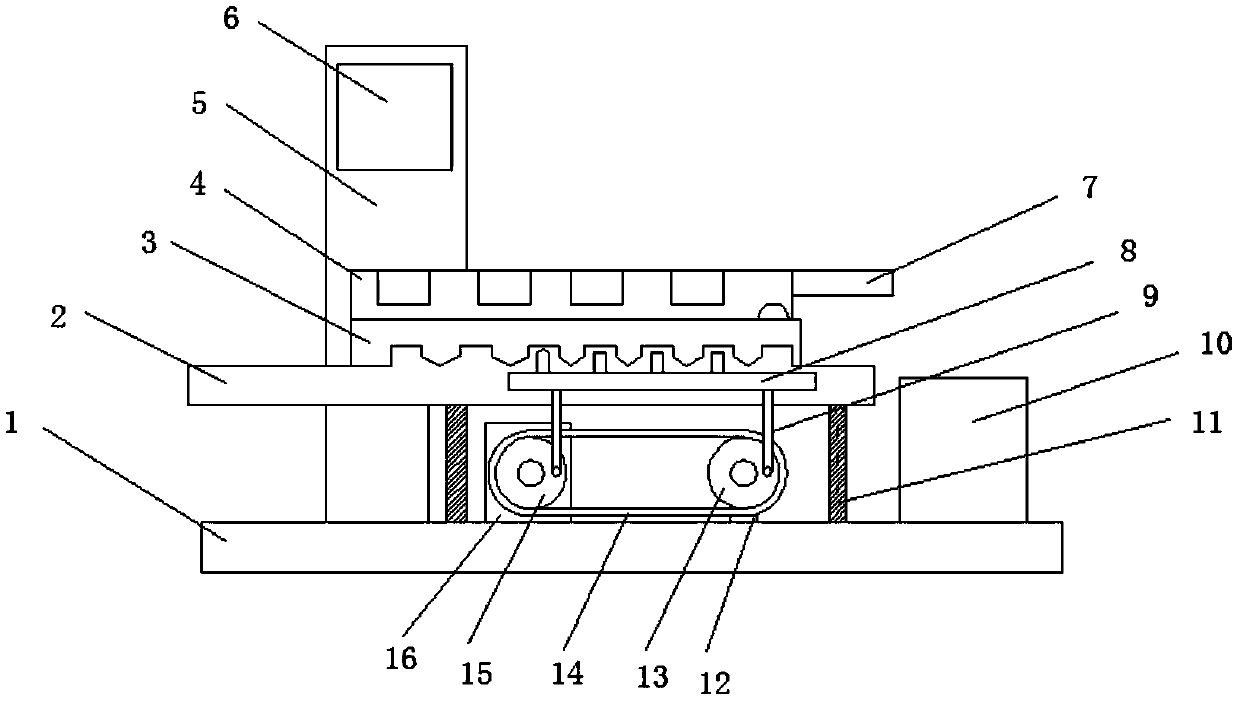

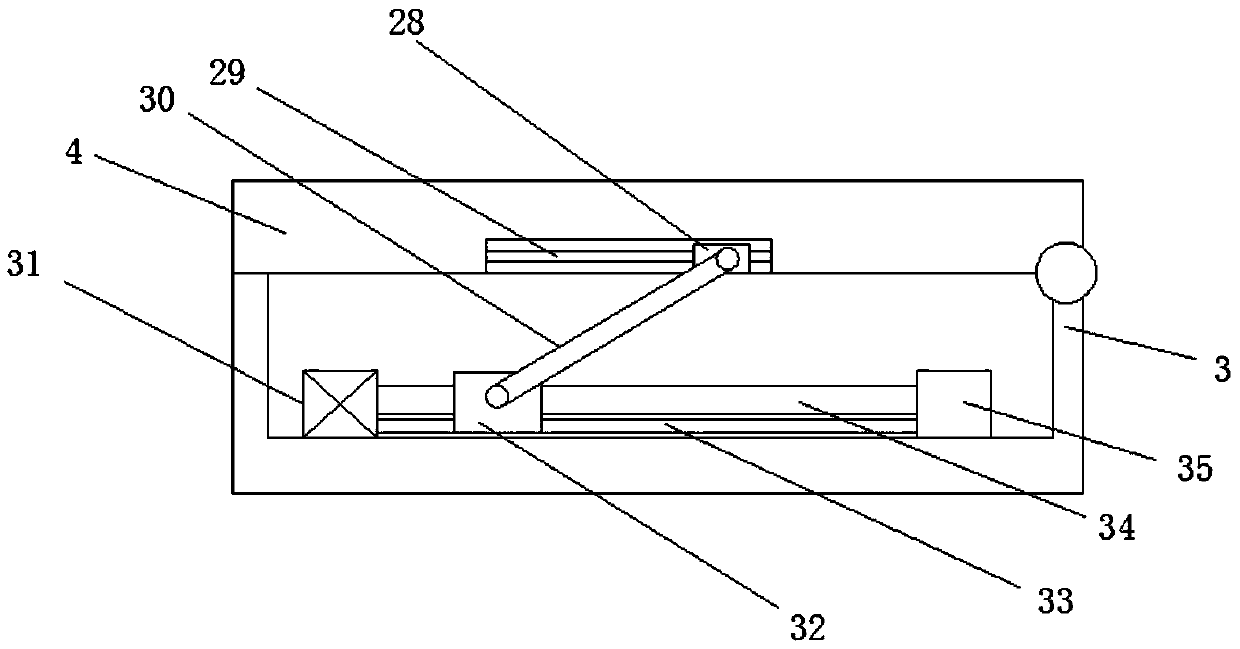

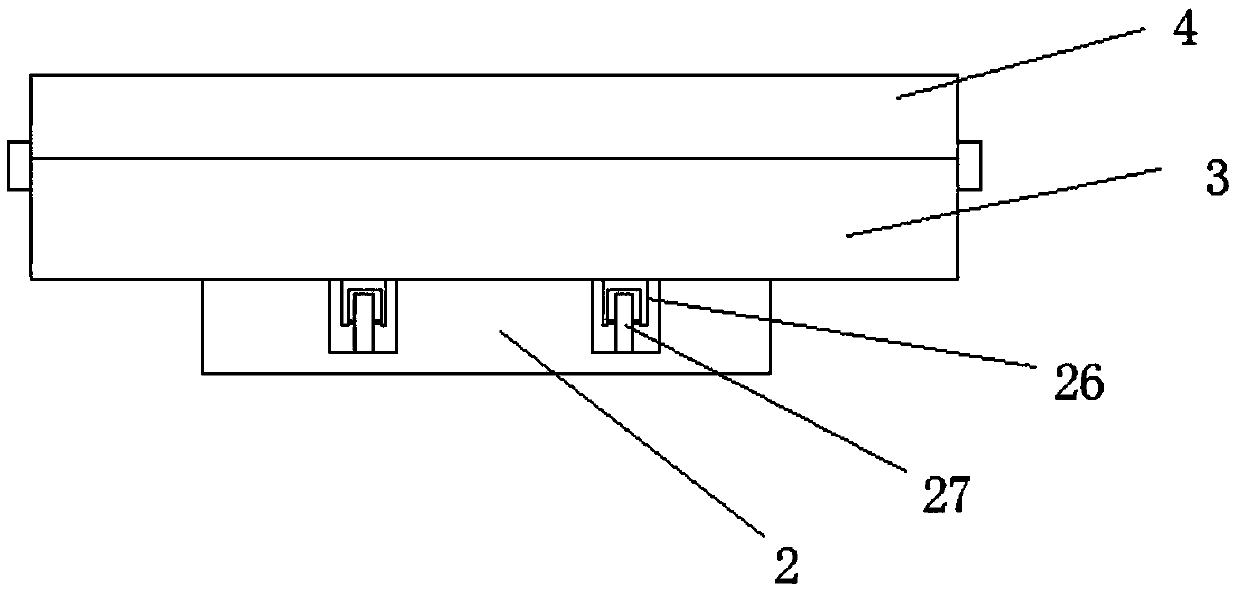

[0023] refer to Figure 1-5 , a kind of drilling and damping equipment for auto parts processing, including a base plate 1, two support rods 11 are fixedly connected to the upper side wall of the base plate 1, and the upper ends of the support rods 11 are fixedly connected to a support plate 2, and are located on the two support rods 11. The upper side wall of the bottom plate 1 between them is fixedly connected with the first motor 16 and the mounting plate 12, the first motor 16 is a servo motor, the model is DSM32, the output end of the first motor 16 is fixedly connected with the first pulley 15, the mounting plate 12 The upper rotation is connected with a rotating shaft, and one end of the rotating shaft is fixedly connected with a second pulley 13, and the first pulley 15 and the second pulley 13 are connected by a belt 14, and the eccentric parts of the first pulley 15 and the second pulley 13 are connected with a first pulley for rotation. Rotating rod 9, the upper end...

Embodiment 2

[0028] The difference from Example 1 is that both the first pulley and the second pulley are shock-absorbing pulleys, which are made of high-damping rubber composite materials, and their formula by mass is: natural rubber component 91, carbon nanometer Tube components 6-5, petroleum resin components 9-22, plasticizer components 5-15, activator components 4-7, accelerator components 0.5-1.5, vulcanizing agent components 1-2, anti-vulcanization Return to the original agent components 5-6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com