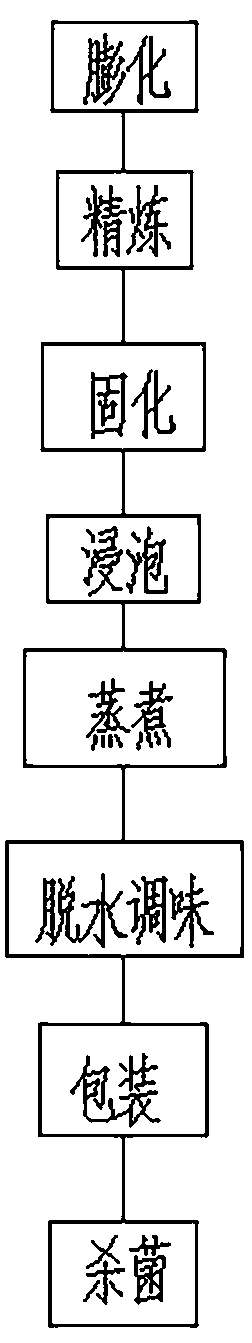

Production technology of konjac ready-to-eat foods

A production process and food technology, applied in the field of konjac instant food production process, to achieve the effect of reducing labor intensity, saving labor cost, and reducing production risk coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

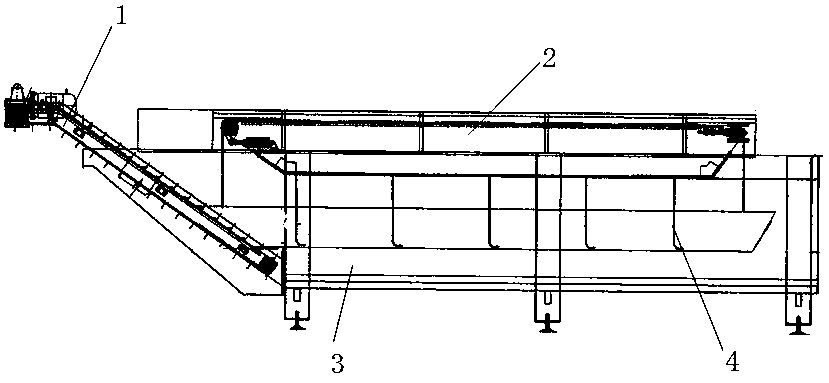

[0024] as attached Figures 1 to 2 Shown, a kind of konjac instant food production technology comprises the following steps:

[0025] The first step, puffing: first add a certain amount of water into the puffing tank, start stirring, pour in a certain amount of konjac flour and starch, continue stirring until it becomes a uniform paste, and let it stand for 1-2 hours;

[0026] The second step, refining: the puffed material is formed into a gel form through a refining machine, which is a semi-finished product;

[0027] The third step, curing: the semi-finished product is cured and matured by hot water in the curing pipeline. After the semi-finished product leaves the curing pipeline, it can directly enter the flower cutting machine through the slope conveying device. The temperature of the hot water is 85 ° C ~ 100 ° C;

[0028] The fourth step, soaking: the semi-finished product is cut into sections by the flower cutting machine, and the semi-finished product enters the soaki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com