Effectively mute reciprocating pump

A reciprocating pump, silent technology, applied in the field of reciprocating pump, can solve the problems of high noise, environmental impact, complex noise reasons, etc., to achieve the effect of easy maintenance and reduce the possibility of breaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

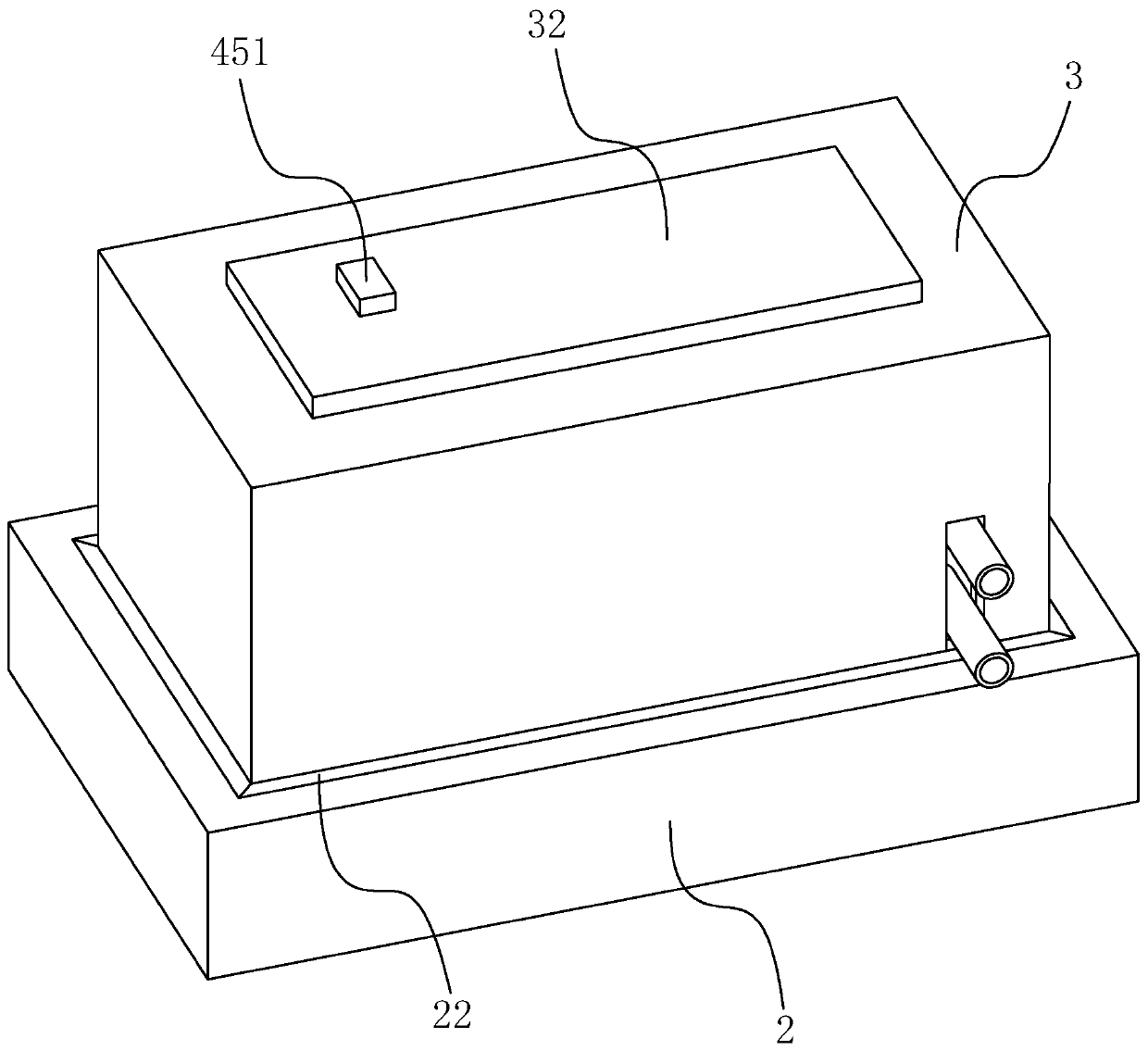

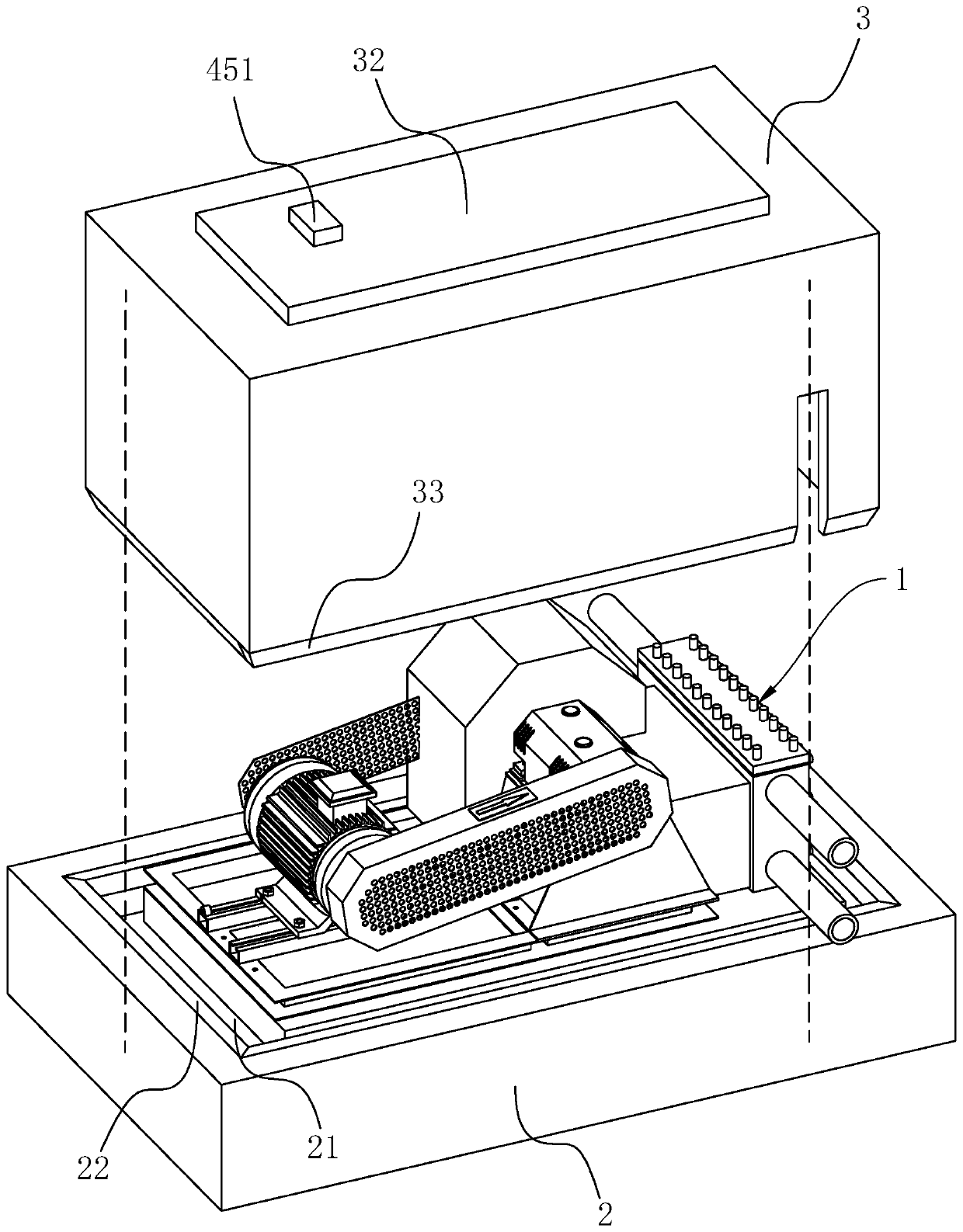

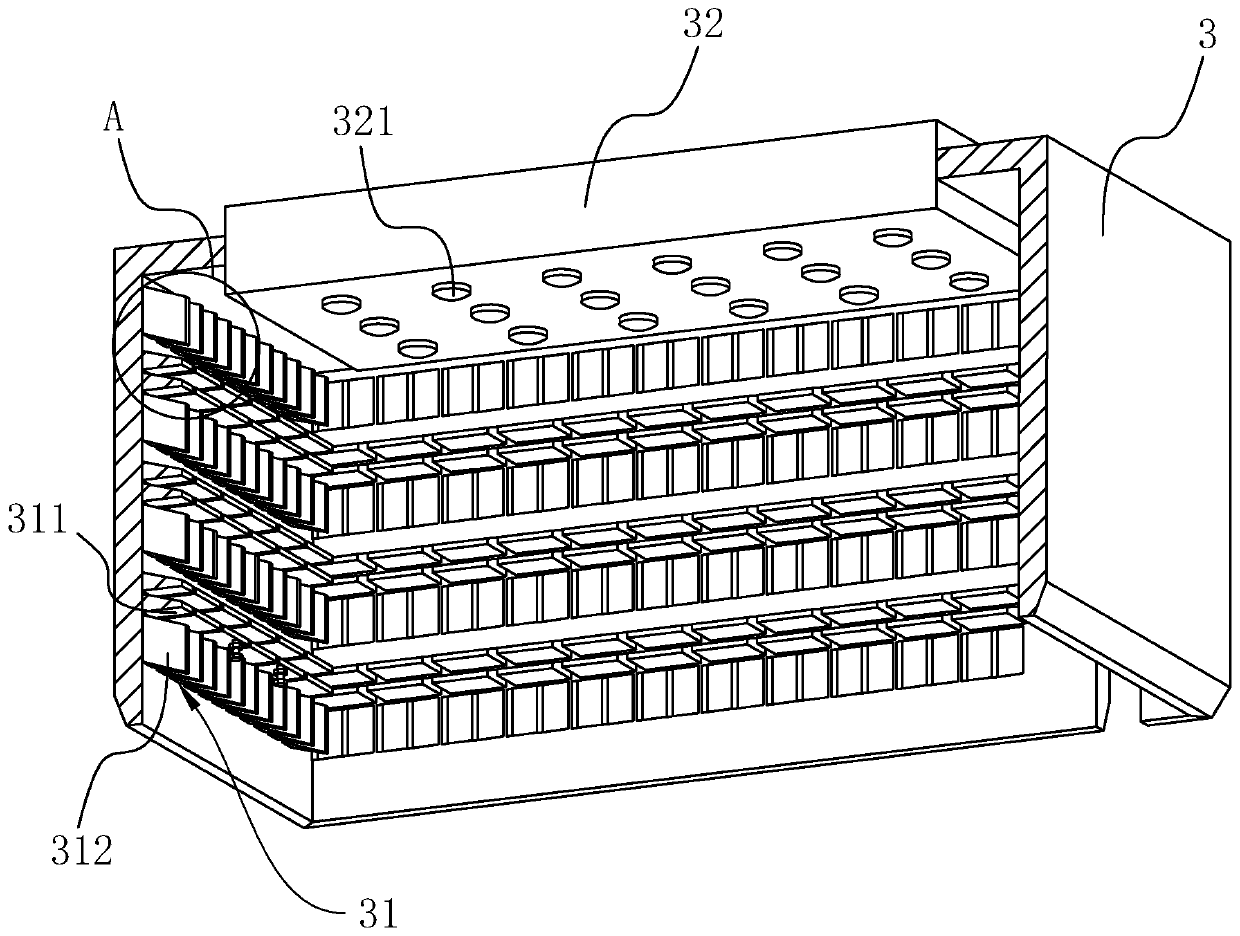

[0046] Example: An effectively silent reciprocating pump such as figure 1 and figure 2 As shown, it includes a base 2 and a reciprocating pump body 1 fixedly connected to the base 2 . The base 2 is made of elastic materials such as hard rubber and 65Mn. The base 2 is connected with a soundproof cover 3 that can surround the reciprocating pump. The base 2 is provided with a snap-in groove 21 that matches the sound-proof cover 3. The base 2 is fixedly connected with a buffer layer 22 near the snap-fit groove 21. The buffer layer 22 consists of Made of elastic materials such as TPEE, TPR, etc., the soundproof cover 3 can be snapped into the buffer layer 22. The soundproof cover 3 is used to block the noise from the reciprocating pump body 1, and the soundproof cover 3 can be removed from the base 2, which is convenient for the user to overhaul the reciprocating pump.

[0047] Such as figure 2As shown, the soundproof cover 3 is provided with an inclined surface 33 near the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com