Smoke and dust removal equipment for asphalt pavement maintenance vehicles

A technology for smoke elimination and dust removal, asphalt pavement, applied in the separation method, use of liquid separation agent, separation of dispersed particles, etc., can solve the problems of poor dust removal effect, large occupied area, pollution of the environment, etc., achieve small size and easy operation, and improve purification and dust removal Effect, dust removal thorough effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

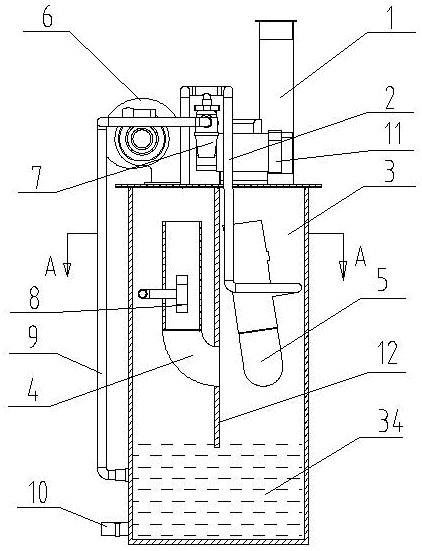

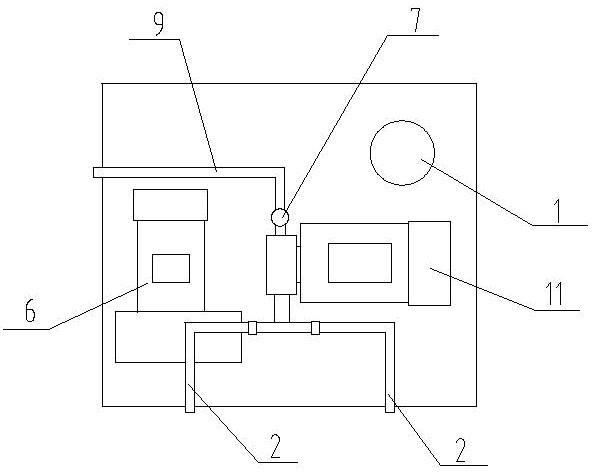

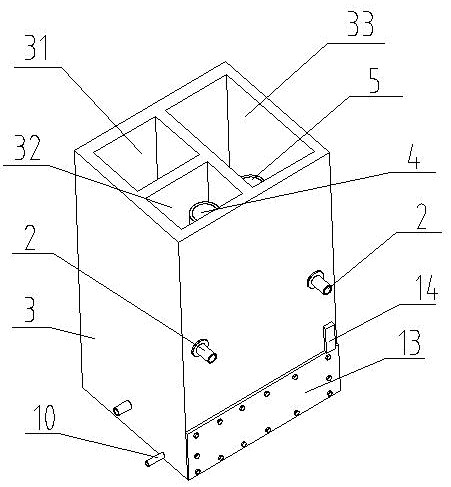

[0017] refer to Figure 1-5 , a kind of asphalt pavement maintenance vehicle smoke elimination and dust removal equipment, including a box body, an end cover is buckled on the top of the box body, an induced draft fan, a smoke exhaust tube and a self-priming electric pump are fixedly arranged on the end cover, and the upper end of the box body 3 is formed by a partition plate 12 Divided into three chambers, namely the smoke inlet chamber 31, the transfer chamber 32 and the smoke outlet chamber 33, the lower end of the box body 3 is a water storage chamber 34, the smoke inlet chamber 31, the transfer chamber 32 and the smoke outlet chamber 33 pass through the lower storage chamber The water chambers 34 communicate with each other, and a sealing spacer is pasted on the upper end surface of the casing 3 peripheral wall and the upper end surface of the partition plate 12. The first air inlet tube 4 is arranged in the transfer chamber 32, and the lower port of the first air inlet tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com