U-type double-sided lysimachia sikokiana flow guide line in threshing chamber of harvester

A technology of diversion line and threshing chamber, which is applied in the field of U-shaped double-sided grass discharge diversion line, which can solve the problems of screen blockage, affecting the operating efficiency of harvesters, increasing the load of threshing chamber and sieve box, and avoiding blockage of screen net effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The U-shaped double-sided grass discharge guide line in the threshing chamber of the harvester of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments:

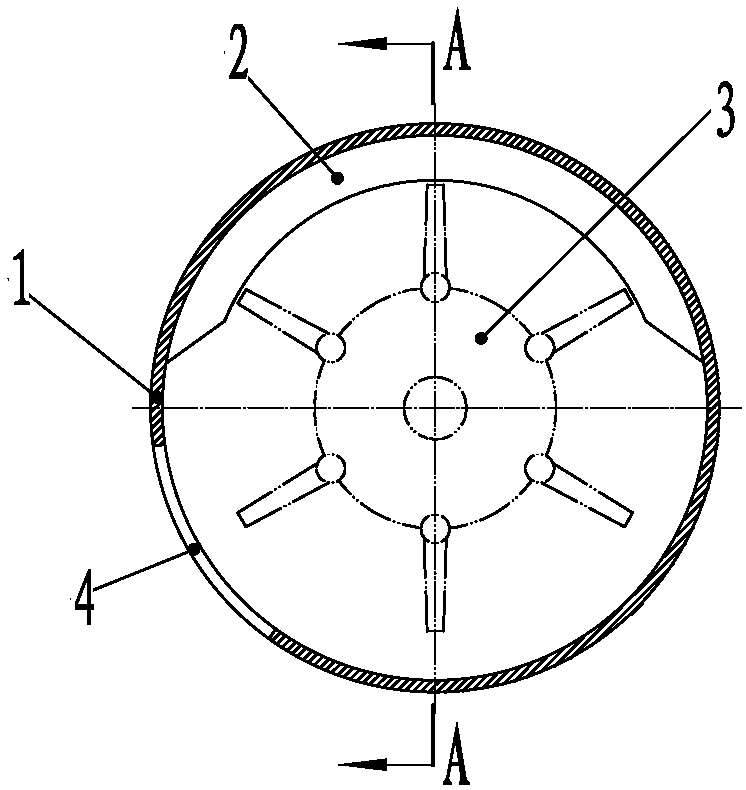

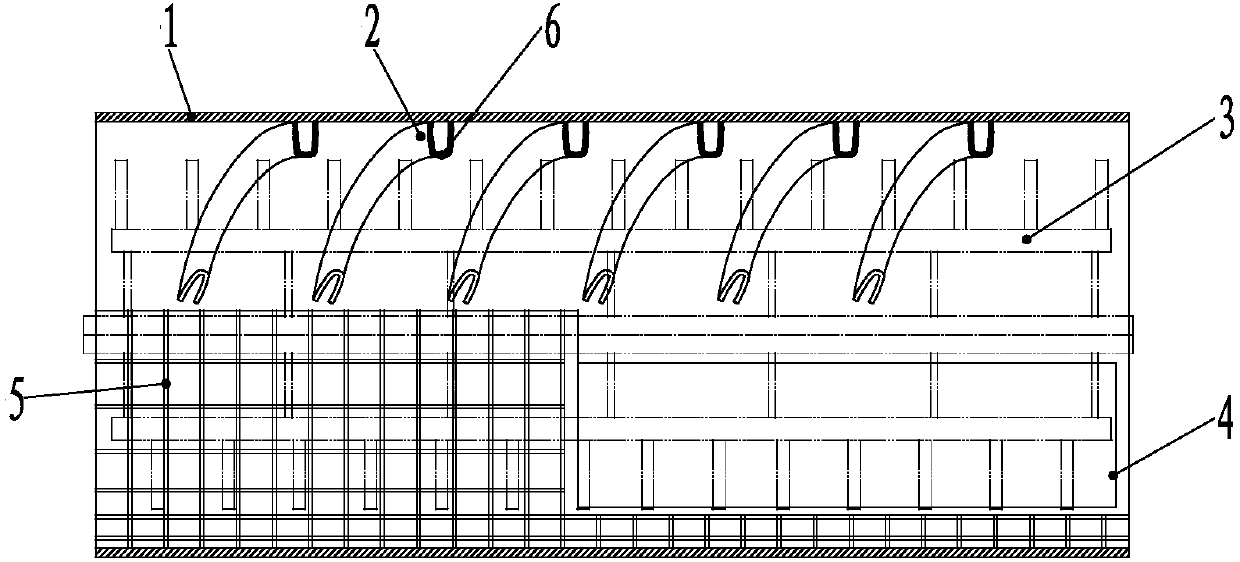

[0012] figure 1 It is a structural schematic diagram of the U-shaped double-sided grass discharge guide line in the threshing chamber of the harvester of the present invention, figure 2 yes figure 1 A-A sectional view in . In the figure, the U-shaped double-sided grass discharge guide line 2 in the threshing chamber of this harvester is welded on the upper semi-cylindrical wall of the harvester's threshing chamber, and the cross section of the grass discharge guide line 2 is "U" The U-shaped open end of the grass diversion line is welded on the upper semi-cylindrical wall of the harvester threshing chamber cylinder 1, and the U-shaped arc end 6 of the grass discharge diversion line faces the cylinder axis of the harvester threshing chamber.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com