Fully wrapped multi-layer spiral crimping and setting device for inner lining

A sizing device and spiral technology, applied in the field of textiles and garments, can solve the problems of difficult control of fabric flexibility and elasticity, low efficiency, and troublesome manual curling, etc., and achieve the effects of reducing sewing skill requirements, improving production efficiency, and making production simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing and specific embodiment, further illustrate the present invention, should be understood that these embodiments are only for illustrating the present invention and are not intended to limit the scope of the present invention, after having read the present invention, those skilled in the art will understand various aspects of the present invention Modifications in equivalent forms all fall within the scope defined by the appended claims of this application.

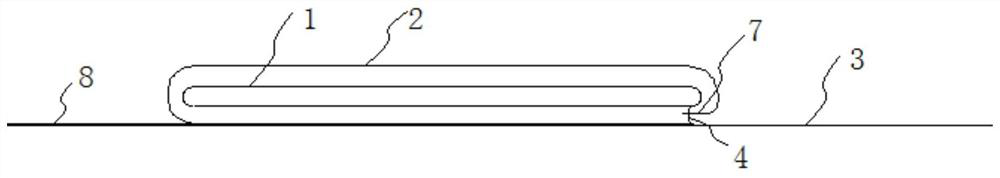

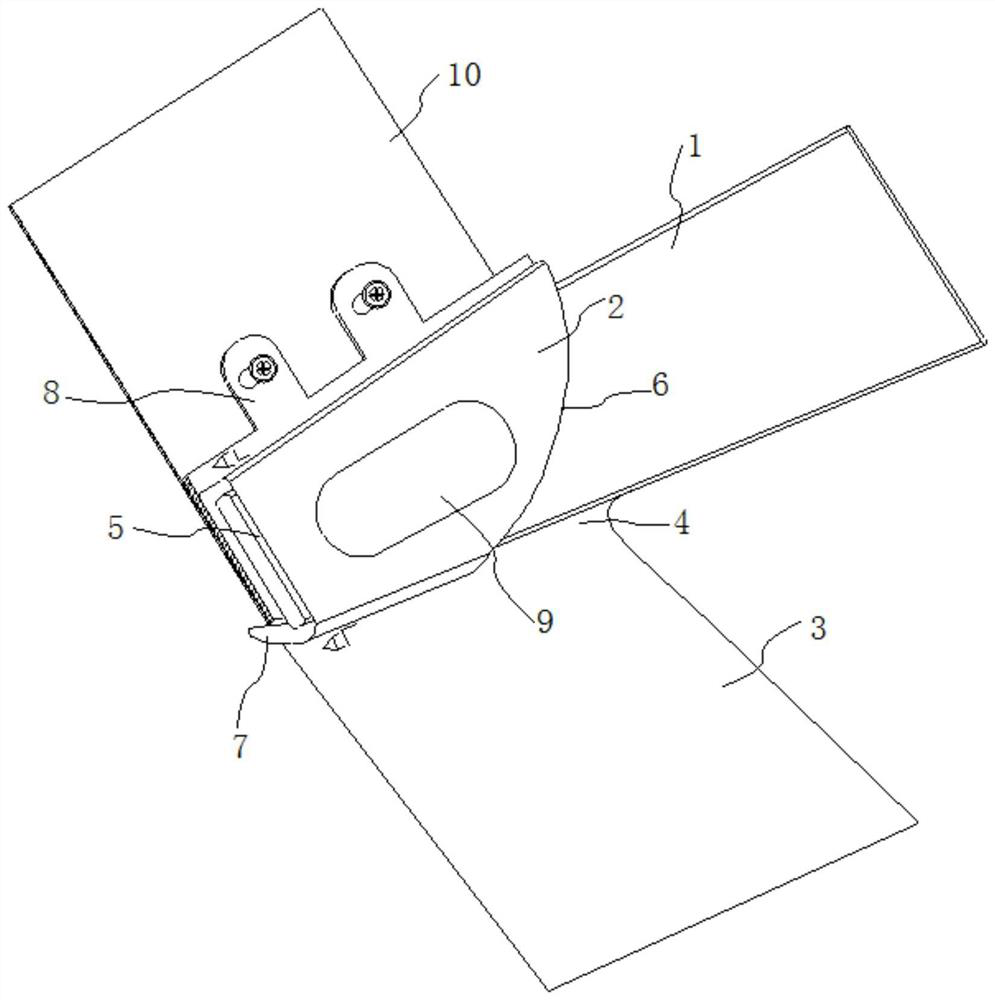

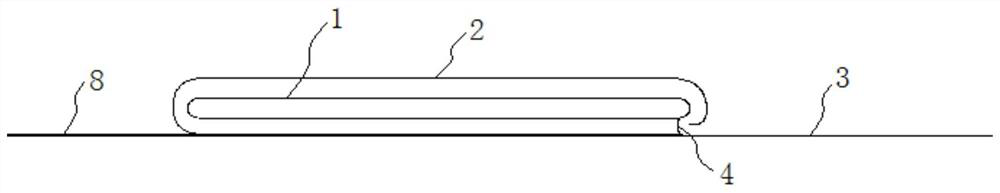

[0018] Such as figure 1 As shown, the liner full-wrapped multi-layer spiral crimping and shaping device of the present invention mainly includes a substrate conveying trough, a spiral drum, a feeding flank, and a positioning mounting plate, wherein:

[0019] The substrate conveying trough is a long flat tube, and has a shape matching the spiral drum, all of which are tapered. The tapered shape of the spiral reel can force the fed fabric to be folded automatically as the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com