Front partition plate lower mounting plate and cross beam assembly

A front bulkhead and mounting plate technology, which is applied to vehicle components, transportation and packaging, and upper structures, can solve problems that affect assembly efficiency, excessively long dimensional chains, and inability to ensure connection strength, and achieve faster assembly efficiency and dimensional chains. The effect of less and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

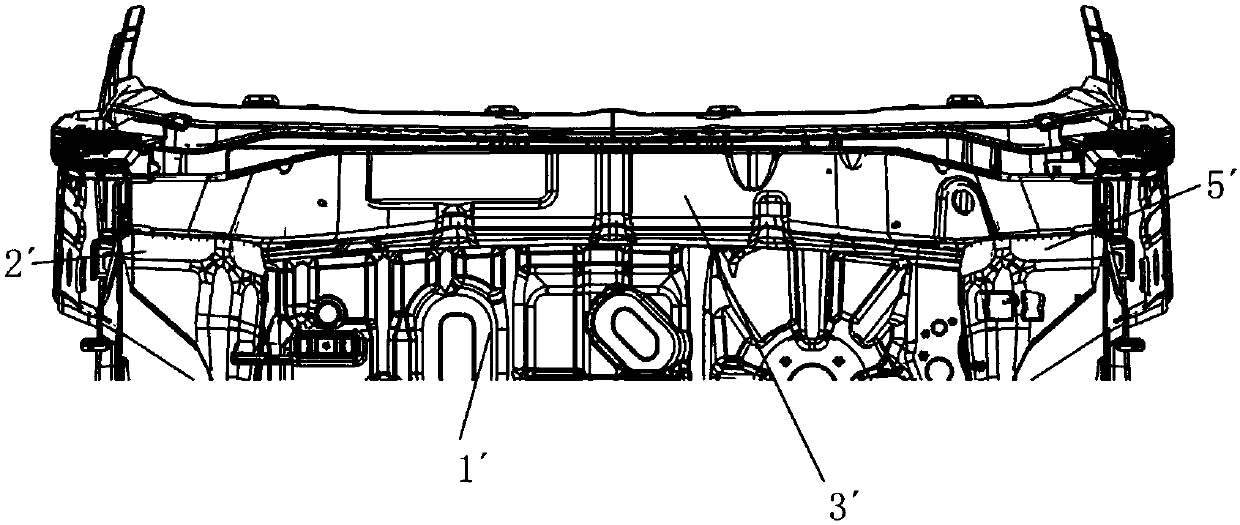

[0038] The following with attached Figure 3 to Figure 9 A crossbeam assembly of the lower mounting panel of the front bulkhead of the present invention is further described in detail.

[0039] A crossbeam assembly of the lower mounting plate of the dash panel of the present invention, please refer to Figure 3 to Figure 9 As shown, it includes a front bulkhead lower mounting plate 1 and a cross beam 2. The front bulkhead lower mounting plate 1 includes a bulkhead horizontal wall 10, a first vertical wall 11 and a second vertical wall 12. The first vertical wall The straight wall 11 and the second vertical wall 12 extend horizontally upward and are respectively fixed on the front and rear sides of the horizontal wall 10 of the partition, and the beam 2 is fixed horizontally on the front side of the upper surface of the horizontal wall 10 of the partition. A dash panel 3 is fixed to the rear end of the second vertical wall 12 . Specifically, the crossbeam 2 is installed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com