Forming die and method for composite material special-shaped annular rib structure

A technology of composite materials and molding methods, which is applied in household appliances, other household appliances, household components, etc., can solve problems such as complex structure of ribs, reduced manufacturing efficiency, integration of composite materials, and weakened advantages of lightweight, so as to achieve lay-up Easy to operate, high consistency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

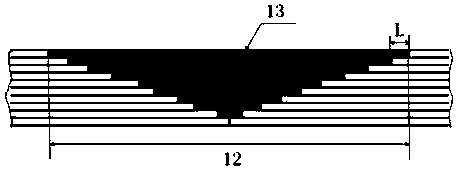

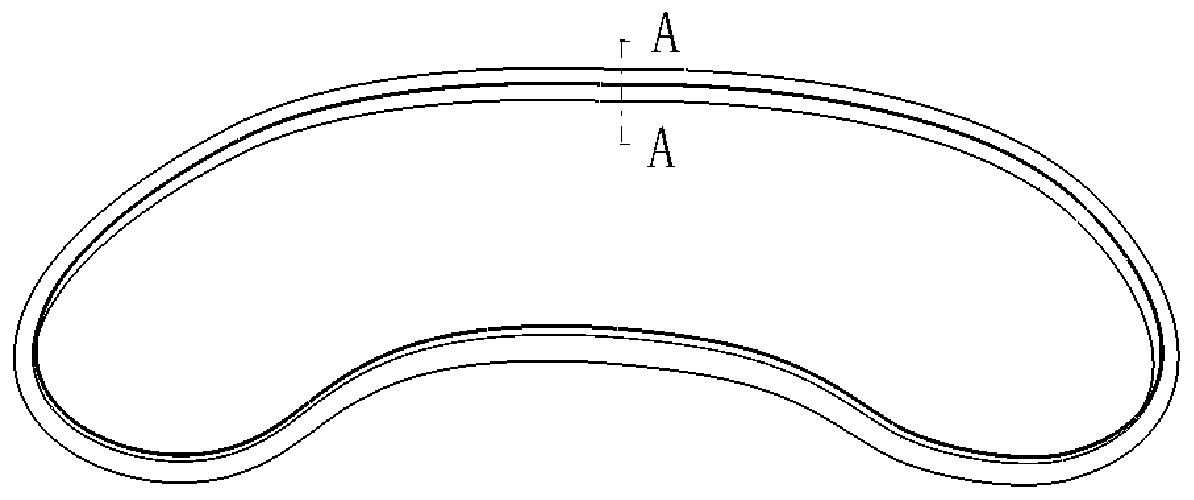

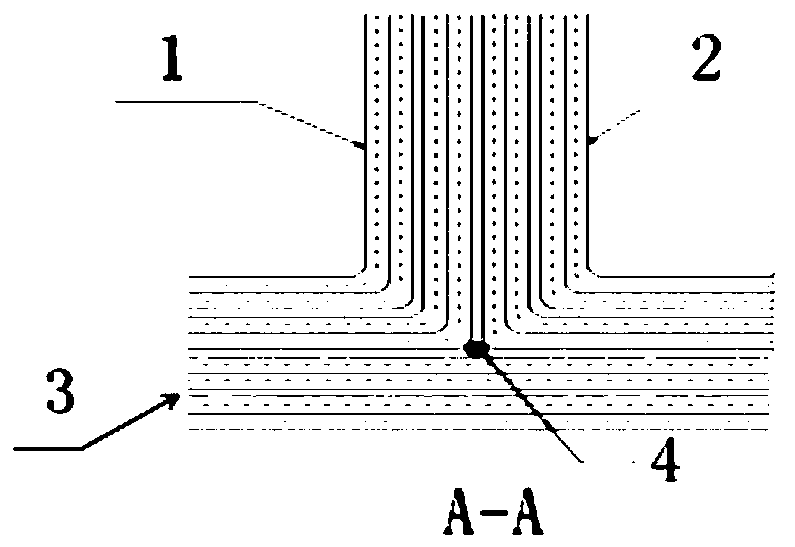

[0027] Such as figure 1 -5 shows the schematic diagram of the overall molding mold for the special-shaped annular rib structure. It can be seen from the figure that the molding mold for the special-shaped annular rib structure includes two parts: the main punch 5 and the vertical rib laying mandrel 6 . The main body punch 5 is an annular structure, and its external shape is consistent with the internal shape of the special-shaped annular rib structure. The vertical bar laying mandrel 2 is a segmented structure, and the position of the ring structure with the largest curvature change is used as the dividing plane 7. Each segment structure includes mandrels on the left and right sides, and the left mandrel 8 and the right mandrel 9 are provided with Precise positioning of the connection hole 10 . The mandrels are mechanically connected by delica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com