Permanent magnet synchronous variable frequency motor rotor punching tool

A variable frequency motor and rotor punching technology, which is applied in the mechanical field, can solve the problems of damage to the positioning keyway, difficulty in the punching process, unequal punching grooves, etc., and achieve good uniformity, save production costs and time, and smooth installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

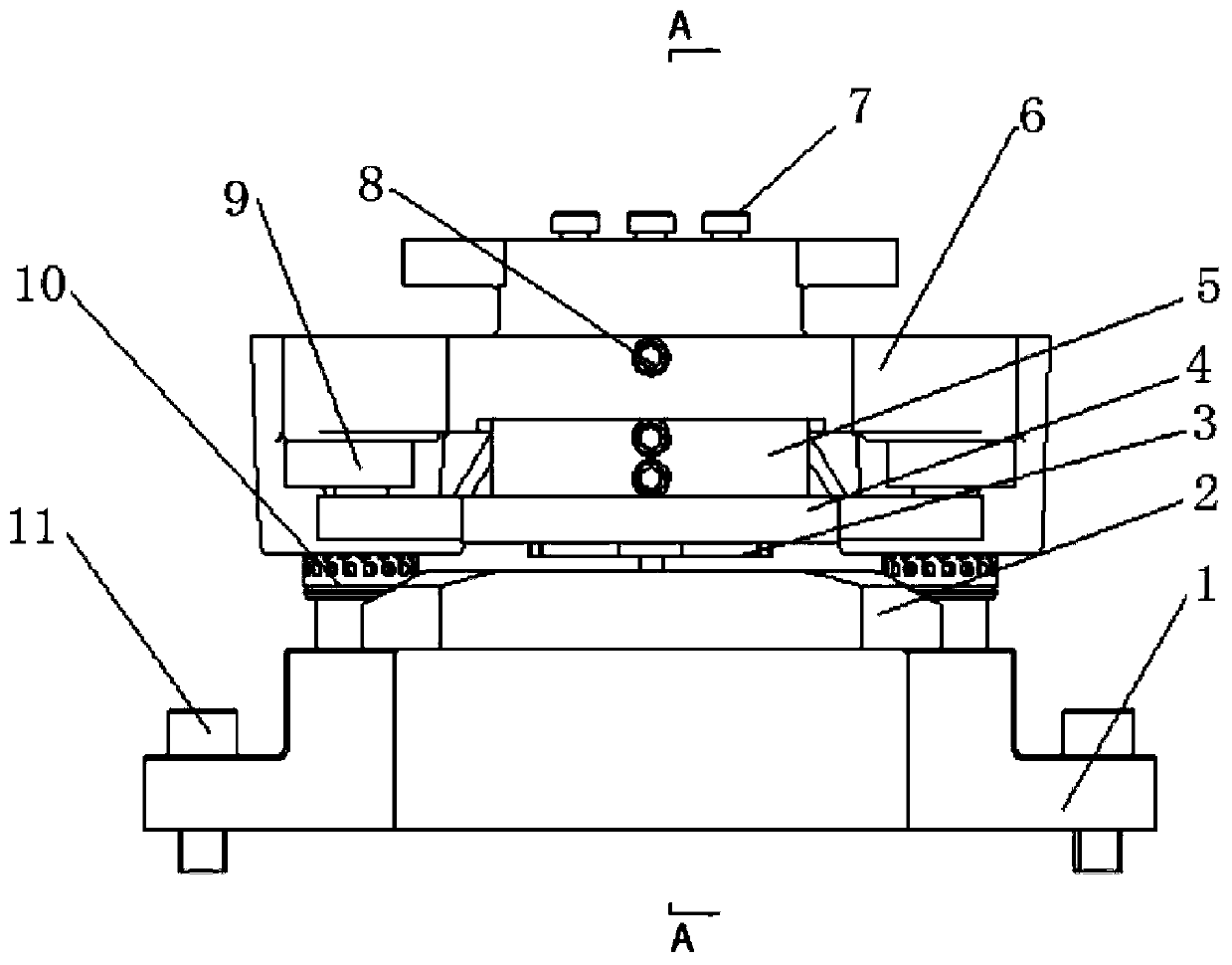

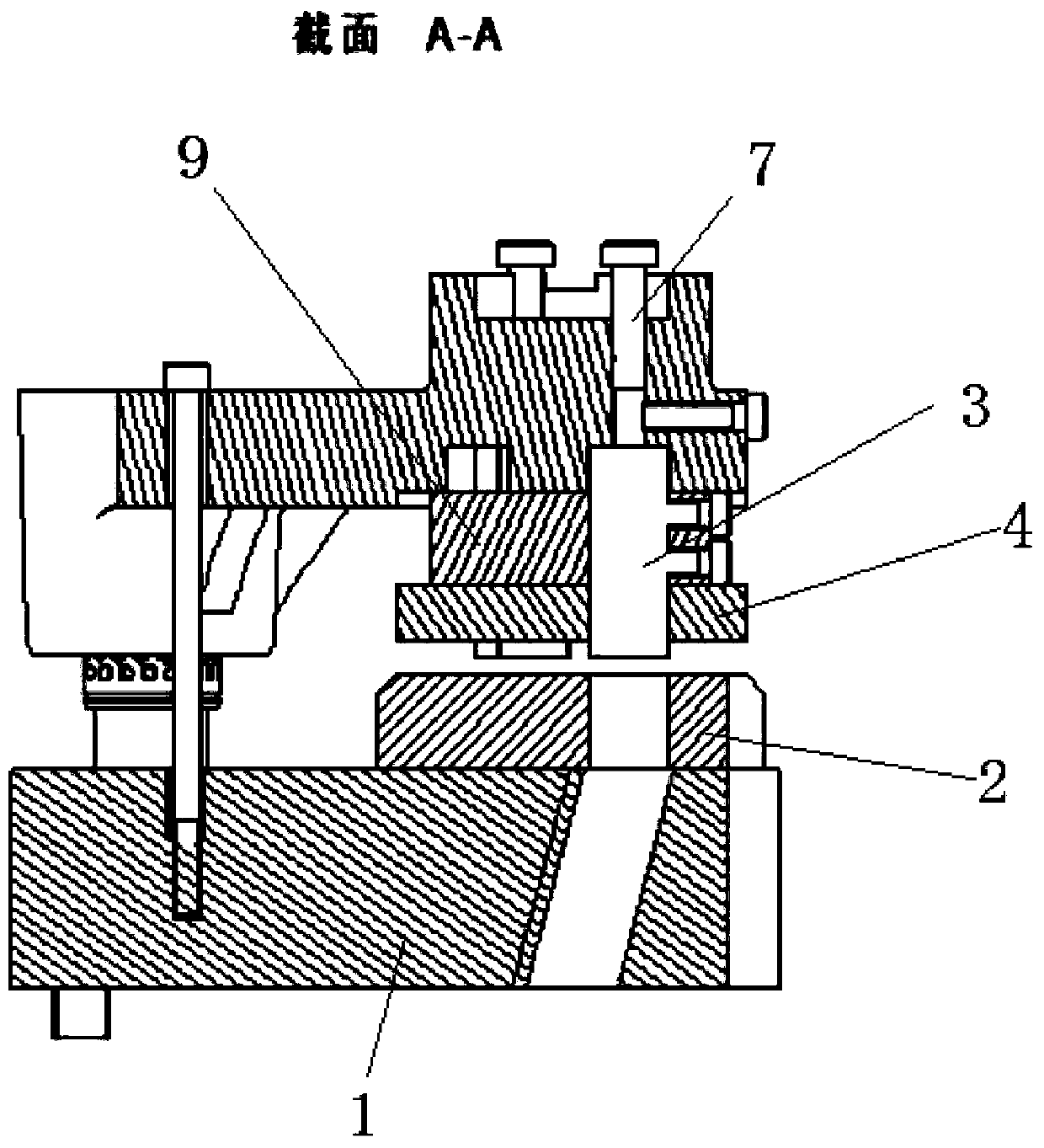

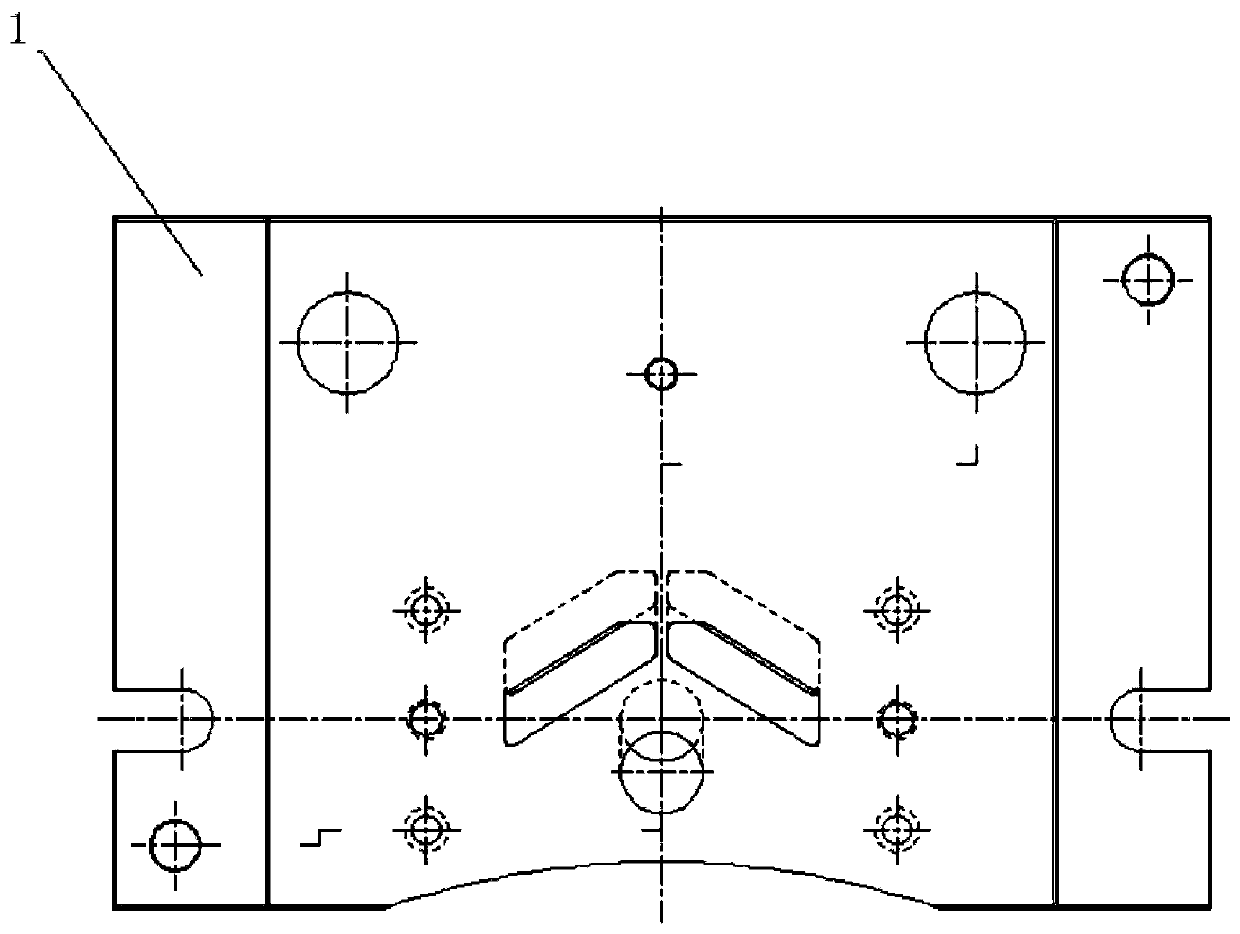

[0033] The present invention is specifically described below in conjunction with accompanying drawing, as shown in the figure, the present invention comprises mold, center positioning device;

[0034] The mold includes a lower mold base 1, a lower mold 2, a punch 3, a stripping plate 4, a fixing plate 5, and an upper mold base 6; a buffer reset device 9; a guide post guide sleeve 10; a bolt 11;

[0035] The lower mold base 1 is provided with a blanking slot, the bottom end is connected with the punching machine workbench through a screw 11, and the top is connected with the lower mold 2; The lower mold base 1 is connected; the grooved punch 3 is fixed on the fixed plate 5 through the set screw; the fixed plate 5 is fixed on the bottom of the upper mold frame 6; Pass through the grooved punch 3 and abut against the lower end of the buffer reset mechanism 9;

[0036] The lower mold base is provided with a slope-shaped notch, so that the punching waste can smoothly fall into the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com