Using method of yam bulbil roller type classifying screen

A kind of spare parts and drum type technology, applied in chemical instruments and methods, sieves, solid separation and other directions, can solve the problems of inability to classify and screen the spare parts of yam, unable to meet the detailed classification and storage of spare parts of yam, etc., to achieve relaxed operating environment conditions and improve labor. Efficiency, the effect of strong grading ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

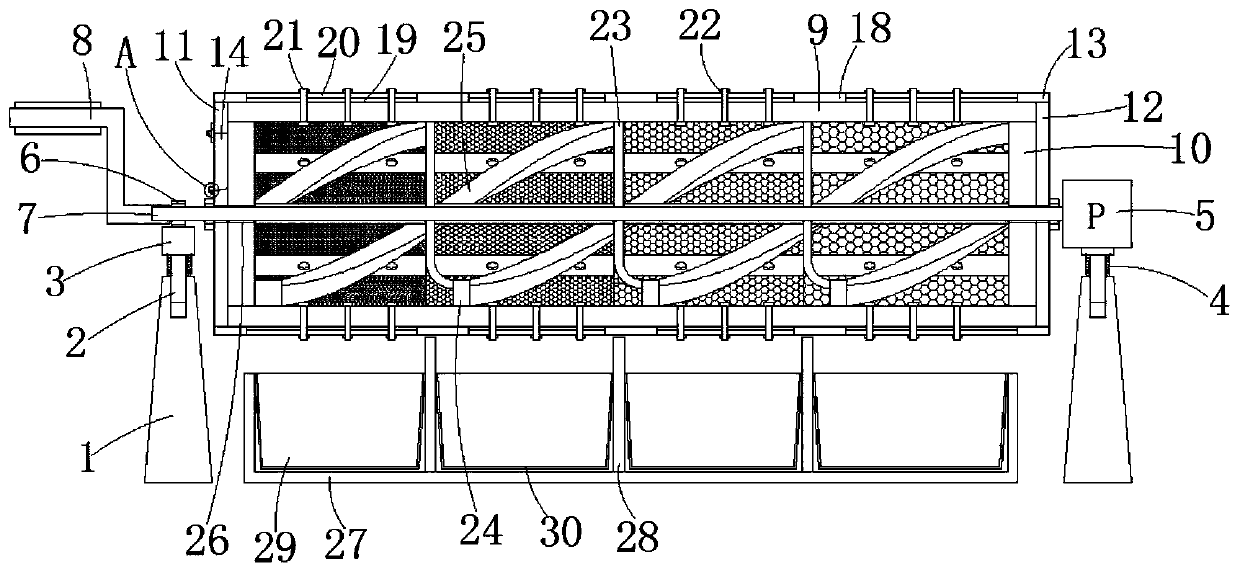

[0037] (1) Install four sets of graded mesh screens: select four sets of graded mesh screens with increasing mesh diameters from left to right, and fix the four sets of graded mesh screens on the frame pillars with mesh strips, fixing bolts and fixing nuts. The grading mesh screen is divided into first-level screen, second-level screen, third-level screen and fourth-level screen from left to right, the mesh diameter of the first-level screen is less than 1.0cm, and the mesh of the second-level screen The diameter is greater than or equal to 1.0cm and less than 1.5cm, the mesh diameter of the third-level sieve is greater than or equal to 1.5cm and less than 2.0cm, and the mesh diameter of the fourth-level sieve is greater than or equal to 2.0cm;

[0038] (2) Correspondingly place the zero surplus collection device: the zero surplus collection device is correspondingly fixed in the area below the four groups of grading screens, and the three interstage baffles divide the internal...

Embodiment 2

[0047] (1) Install four sets of graded mesh screens: select four sets of graded mesh screens with increasing mesh diameters from left to right, and fix the four sets of graded mesh screens on the frame pillars with mesh strips, fixing bolts and fixing nuts. A described grading screen is divided into a first-level screen, a second-level screen, a third-level screen and a fourth-level screen from left to right;

[0048] (2) Correspondingly place the collection device: the collection device is correspondingly fixed in the area below the four groups of grading screens, and the three interstage baffles divide the internal space of the grading collection box into four collection chambers, and the four collection chambers The room is divided into the first-level collection room, the second-level collection room, the third-level collection room and the fourth-level collection room from left to right. The first-level collection room is set facing the first-level screen, and the second-l...

Embodiment 3

[0057] (1) Install four sets of graded mesh screens: select four sets of graded mesh screens with increasing mesh diameters from left to right, and fix the four sets of graded mesh screens on the frame pillars with mesh strips, fixing bolts and fixing nuts. A described grading screen is divided into a first-level screen, a second-level screen, a third-level screen and a fourth-level screen from left to right;

[0058] (2) Correspondingly place the collection device: the collection device is correspondingly fixed in the area below the four groups of grading screens, and the three interstage baffles divide the internal space of the grading collection box into four collection chambers, and the four collection chambers The room is divided into the first-level collection room, the second-level collection room, the third-level collection room and the fourth-level collection room from left to right. The first-level collection room is set facing the first-level screen, and the second-l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com