Self-leveling lawn laying device

A self-leveling and lawn technology, applied in lawn growth, botanical equipment and methods, spades, etc., can solve problems such as high cost of lawn laying, low work efficiency, and cumbersome work process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

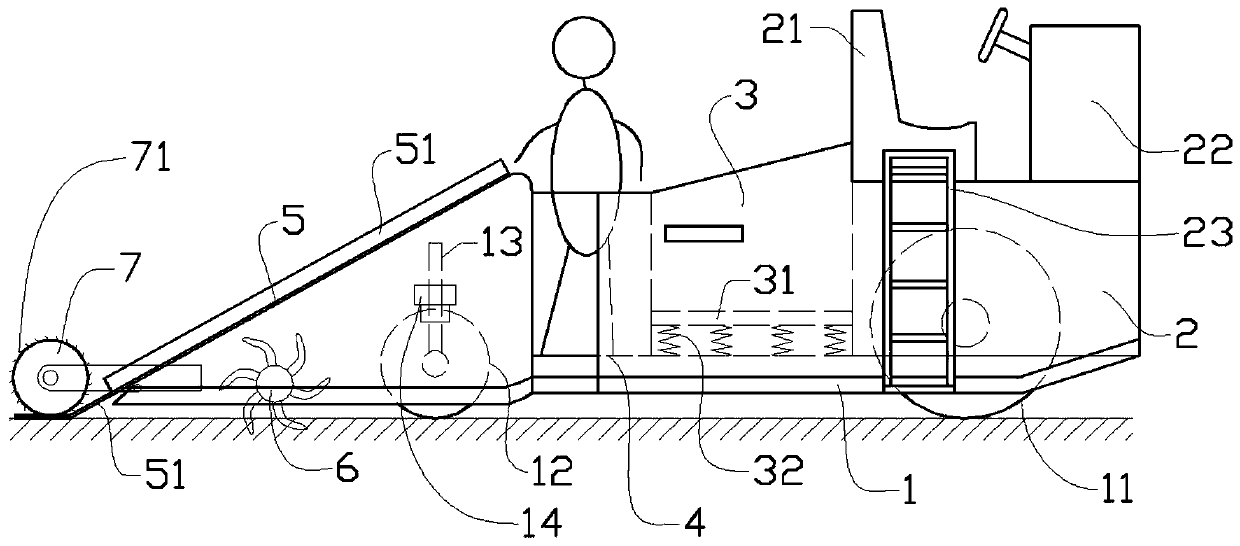

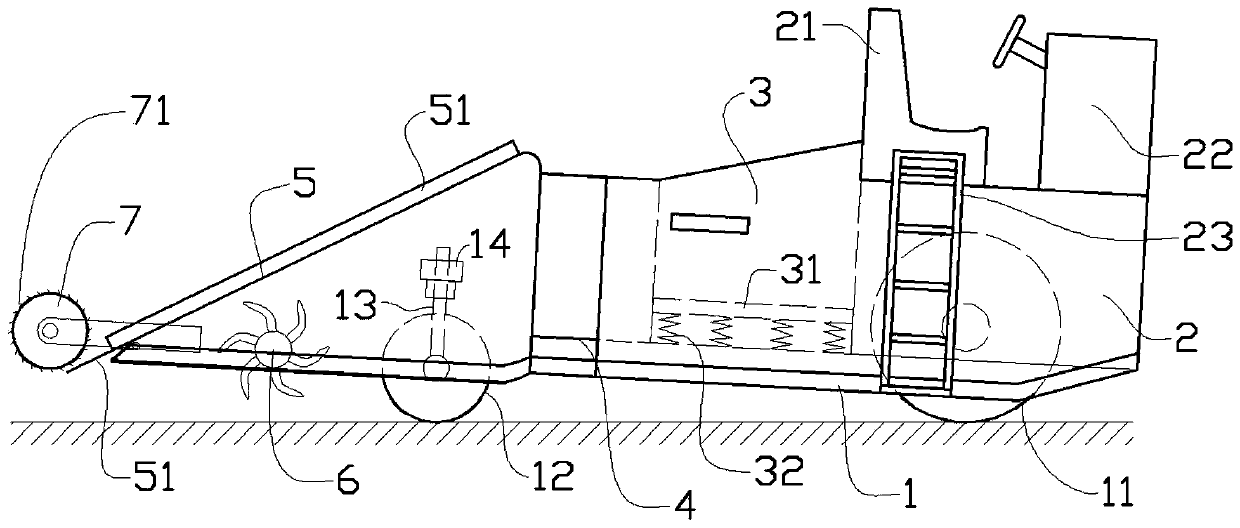

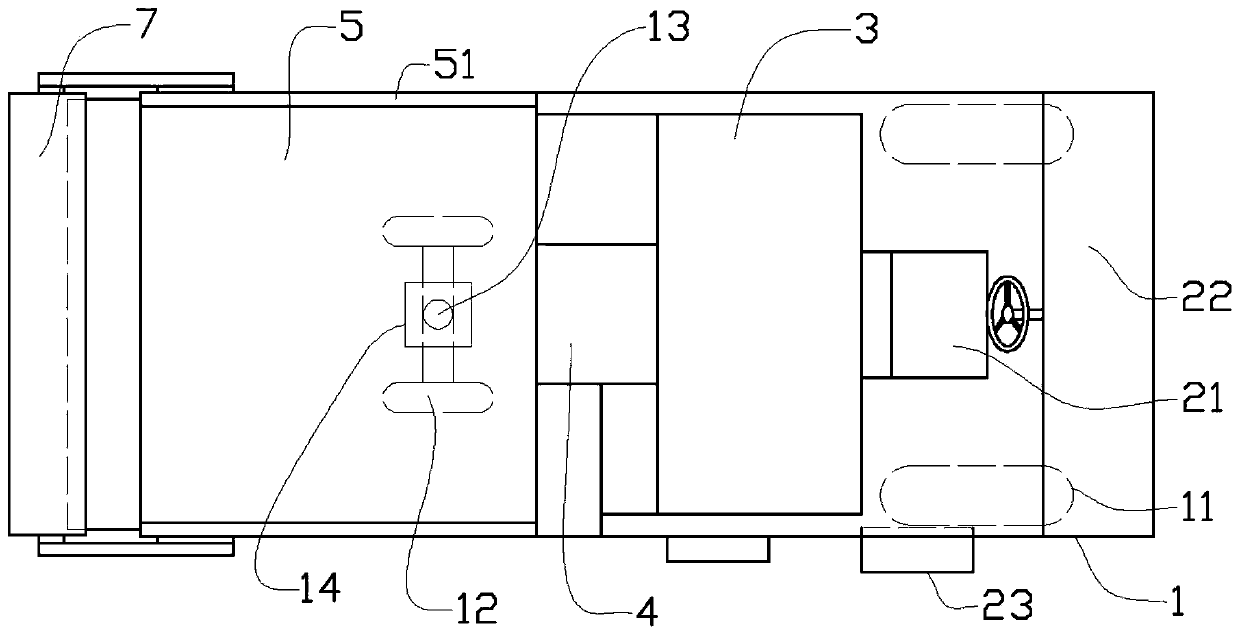

[0017] Below in conjunction with embodiment the present invention is further described:

[0018] Such as figure 1 , figure 2 and image 3 As shown, in the self-leveling lawn laying device, it includes a rectangular frame 1, the front wheel 11 and the rear wheel 12 are installed in the frame 1, and the power module 2 is assembled on the top of the frame 1 from front to rear. , loading box 3, manned platform 4, working inclined plane 5, driver's seat 21 is equipped on the top of described power module 2, and operator's console 22 is equipped at the front of described driver's seat 21, is placed in described loading box 3 Laying lawn; a power machine is designed in the power module 2, and the number of the front wheels 11 is two, and the two front wheels 11 are connected by a front axle, and the power machine is connected to the two front wheels 11 The front axle is connected by transmission, the number of the 12 rear wheels is two, and the two rear wheels 12 are connected th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com