Symmetrical double-shear interface adhesion test device and test method

An interface bonding and testing device technology, which is applied in the direction of using a stable shear force to test the strength of materials, etc., can solve the problem that it is difficult to ensure the horizontal state of the repair material and the concrete specimen, the uneven force on the interface between the repair material and the concrete, etc. Affect the test results and other problems to achieve the effect of reducing the alignment error, simple structure and high control accuracy

Active Publication Date: 2019-11-15

HOHAI UNIV

View PDF8 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] In the process of realizing the present invention, the inventor found that the prior art has at least the following problems: most of the existing tests are carried out based on universal testing machines, and most of the tests use single shear, so it is difficult to ensure that

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

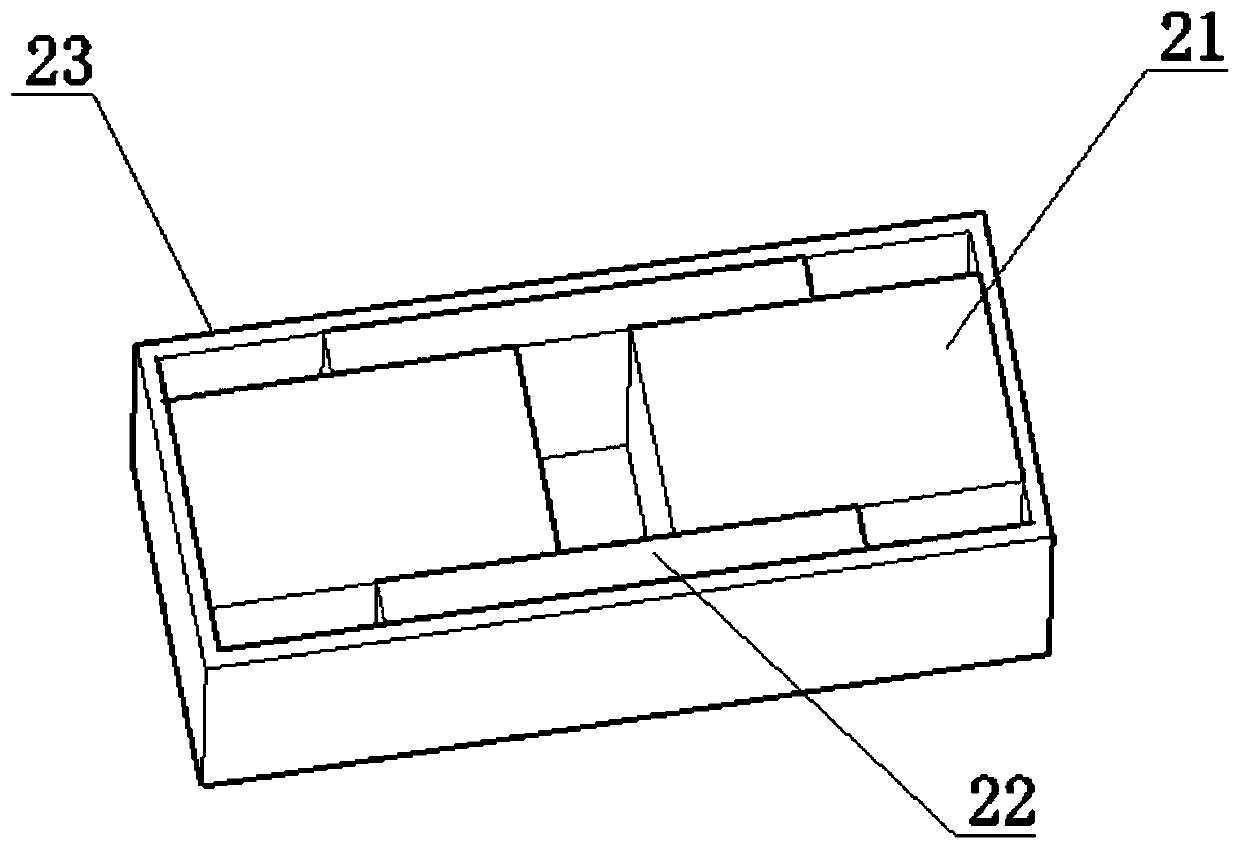

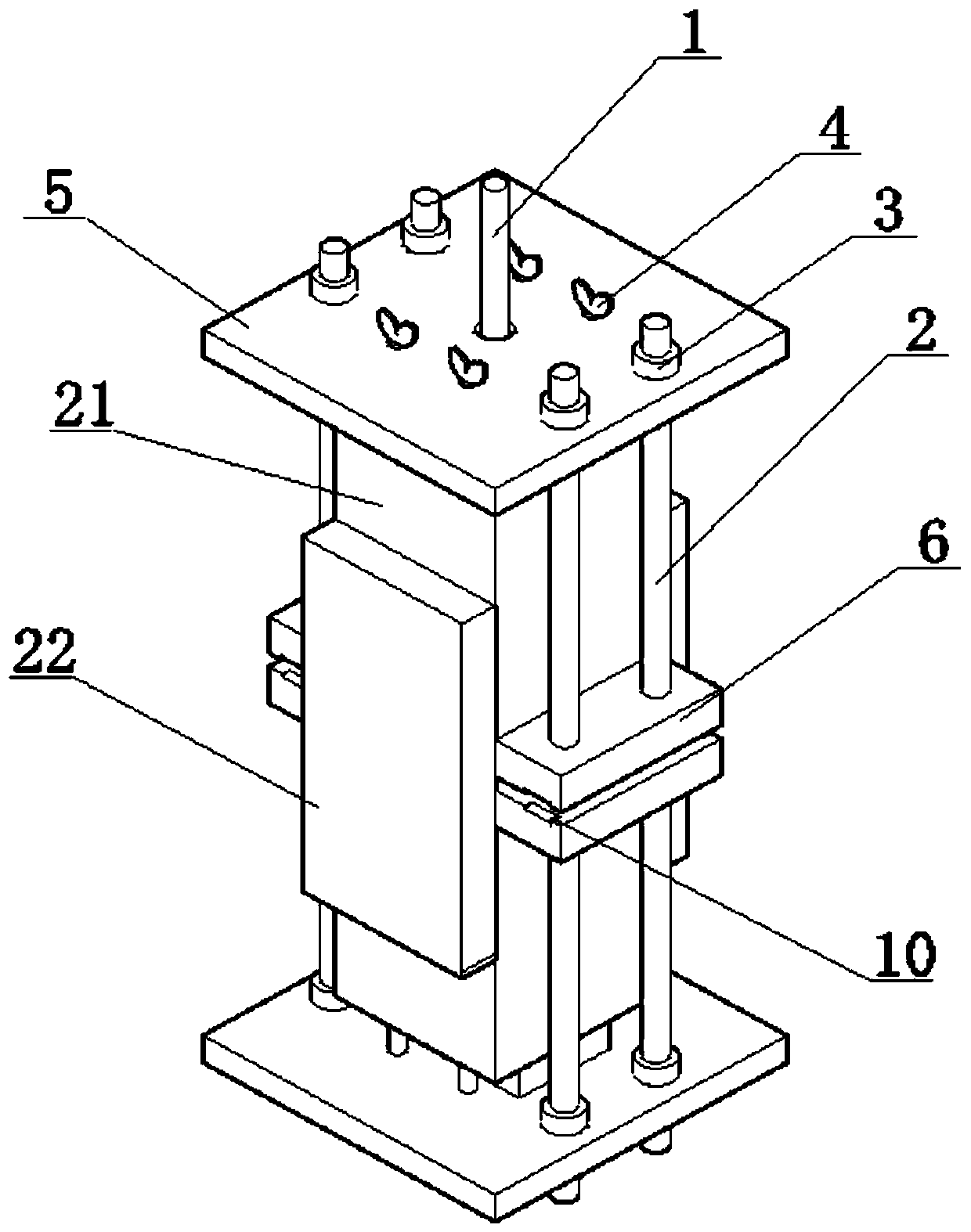

The invention, which belongs to the technical field of mechanical experiment devices, discloses a symmetrical double-shear interface adhesion test device comprising a ball hinge connecting rod, screwrods, a backing plate, plain concrete, a horizontal installation device, an upper bearing plate and a lower bearing plate. Four symmetrical upper bearing plate smooth circular holes are formed in fourcorners of the upper bearing plate; and four lower bearing plate inner threaded holes are formed in the four corners of the lower bearing plate, wherein the holes and the central axis of the upper bearing plate are arranged coaxially. The upper bearing plate and the lower bearing plate are connected with the corresponding lower bearing plate inner threaded holes through the upper bearing plate smooth circular holes by screw rods. The screw rods are provided with upper nuts and lower nuts. According to the symmetrical double-shear interface adhesion test device, centering of a test piece can be controlled; the influence of external forces in the installation process can be avoided; the test accuracy can be improved; the test process is controlled; and the test efficiency can be improved and the convenient test process can be provided.

Description

technical field [0001] The invention belongs to the technical field of mechanical experiment devices, and in particular relates to a symmetrical double-shear interface bonding test device and a test method. Background technique [0002] In the normal working stage of the building structure, the reinforced concrete structure is allowed to have certain cracks, and the transverse cracks caused by the cracking become the channel for the corrosive medium to penetrate into the structure. Junction performance is affected, destroying structural stability. The survey results show that a large number of old reinforced concrete structures are below normal use or structural safety requirements, and there is an urgent need to repair or strengthen these structures to improve their durability and load-bearing capacity. Repair and reinforcement methods include replacing damaged old concrete with new concrete, shotcrete or wire mesh concrete, increasing the cross-sectional area of steel b...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N3/24

CPCG01N3/24

Inventor 侯利军徐冉王越叶子尧严士常黄挺庄宁

Owner HOHAI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com