Joint measurement and calibration method of single-axis translation stage and structured light 3D sensor

A calibration method and sensor technology, applied in the field of visual measurement, can solve problems such as the inability to guarantee high-precision measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

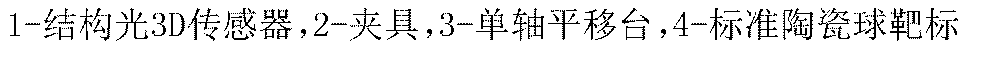

[0039] The specific implementation of the present invention will be described in detail below in conjunction with the accompanying drawings and technical solutions.

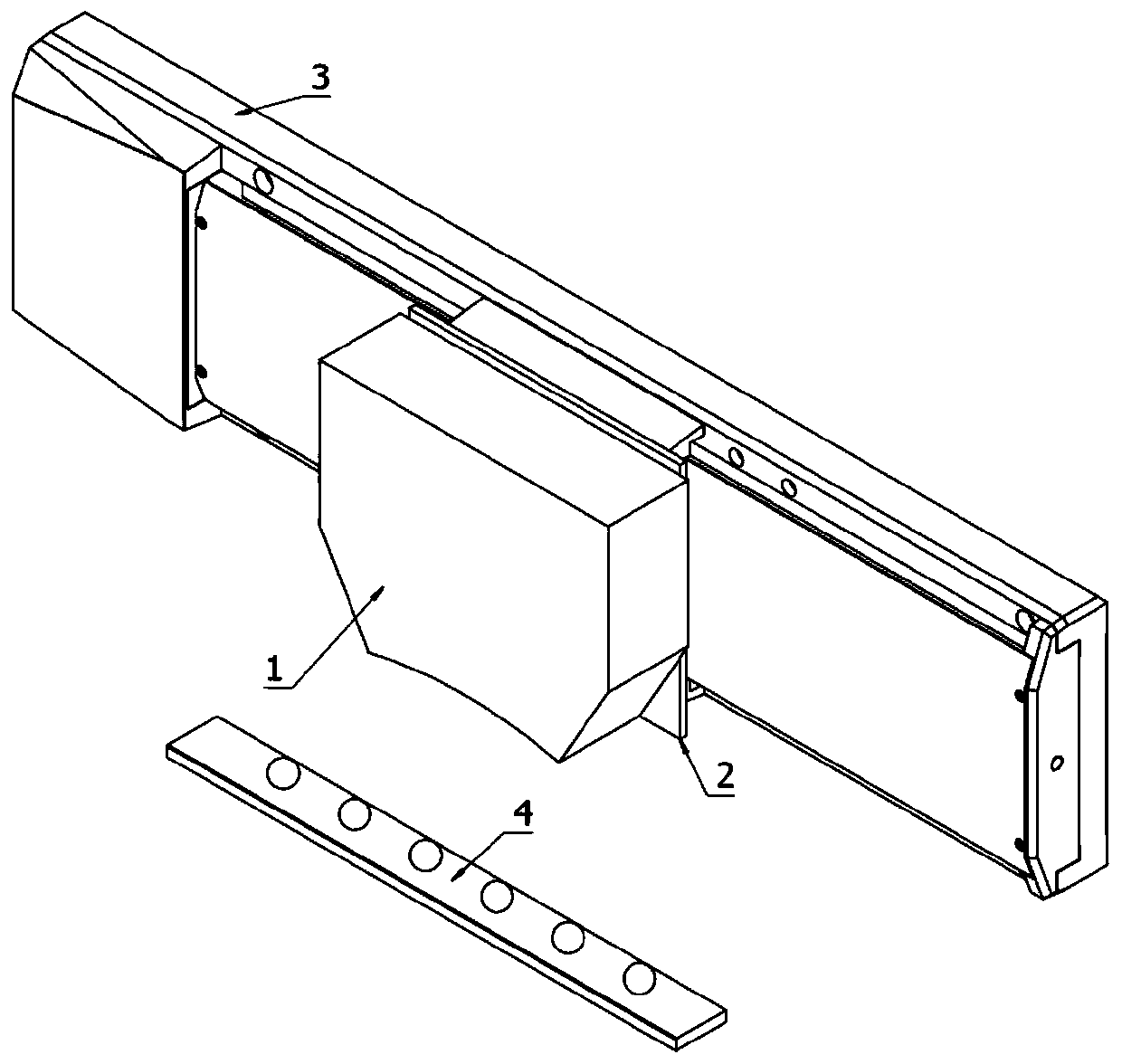

[0040] In the embodiment, the structured light 3D sensor 1 translates with the single-axis translation platform 3, but there is an included angle between the movement direction of the single-axis translation platform 3 and the three coordinate axes of the measurement coordinate system. In high-precision measurement, this included angle It cannot be ignored, it must be considered. In the calibration method of single-axis translation stage and structured light 3D sensor, what needs to be solved is the cosine value of these three included angles.

[0041] The structured light 3D sensor 1 has high resolution in the X, Y, and Z directions, and the selected target ball is a matte ceramic standard target ball with moderate reflection effect, so the collected point cloud data usually has high precision and Reliability, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com