Textile machinery supporting device

A technology for supporting devices and textile machinery, which is applied to mechanical equipment, machines/brackets, supporting machines, etc., can solve the problems of reducing the service life of the supporting device, inability to adjust the supporting height, damage to the supporting device, etc., to achieve easy installation and fixation, practical Strong performance and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

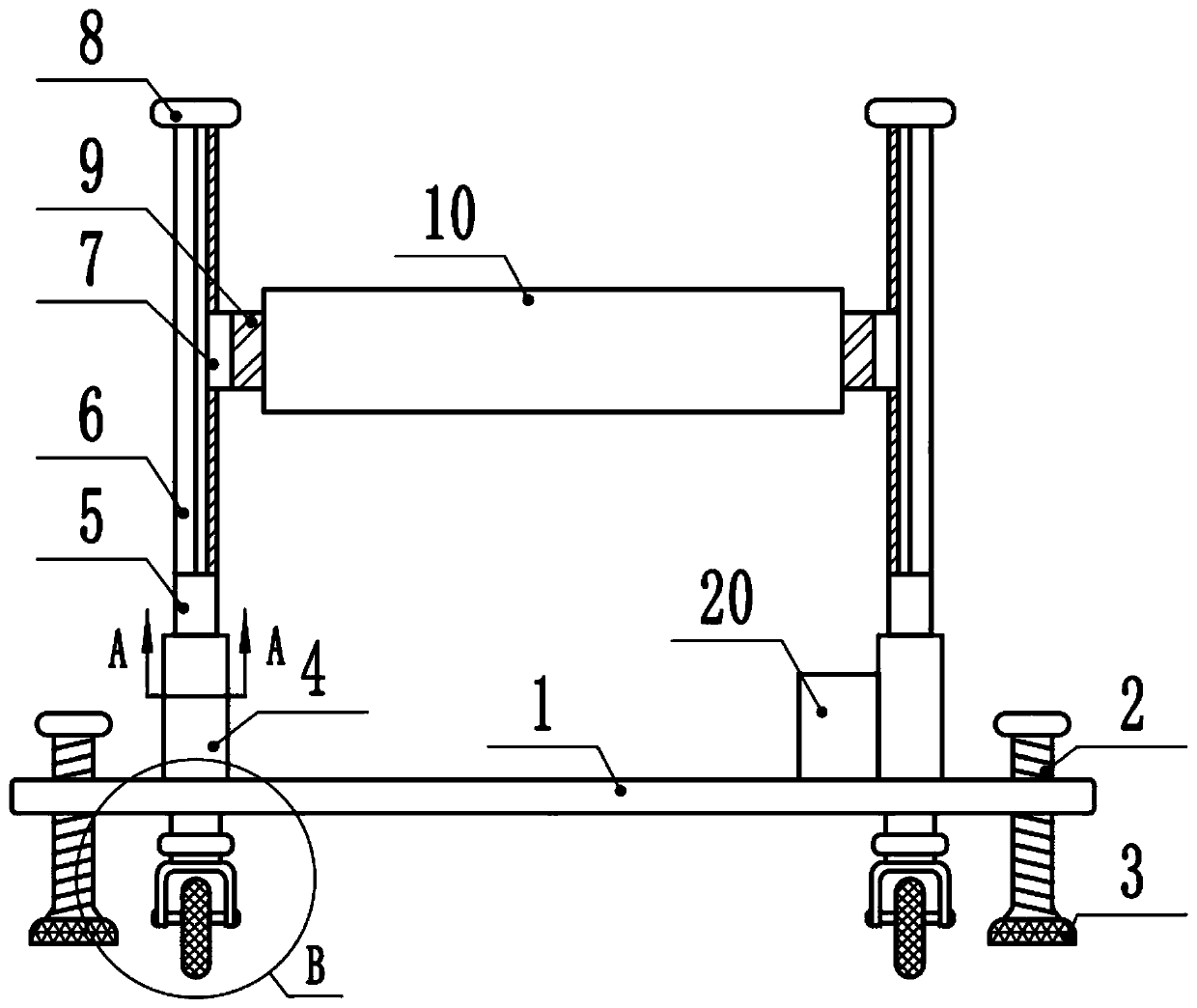

[0024] see Figure 1-4 , a textile machinery supporting device, comprising a base 1, the upper surface of the base 1 is fixedly connected to the left and right sides of the fixed seat 4, the interior of the upper part of the fixed seat 4 is hollow, and the interior of the fixed seat 4 is provided with a chute 13, the bottom of the chute 13 A spring 14 is fixedly connected, the upper end of the spring 14 is elastically fixedly connected with a fixed rod 5, the side of the fixed rod 5 is contacted with the side wall of the chute 13, and the upper end of the fixed rod 5 is fixedly connected with a slide rail 6, and the number of the slide rails 6 is two One, the inner surface of the two slide bars is slidably equipped with a slide cylinder 7, and the slide rail 6 is fixedly connected with a limit block 8 at one end of the fixed rod 5, so as to prevent the slide cylinder 7 from sliding out of the slide rail 6 and play a position-limiting role.

[0025] Specifically, a fixed block ...

Embodiment 2

[0028] see Figure 1-4 , a textile machinery supporting device, comprising a base 1, the upper surface of the base 1 is fixedly connected to the left and right sides of the fixed seat 4, the interior of the upper part of the fixed seat 4 is hollow, and the interior of the fixed seat 4 is provided with a chute 13, the bottom of the chute 13 A spring 14 is fixedly connected, the upper end of the spring 14 is elastically fixedly connected with a fixed rod 5, the side of the fixed rod 5 is contacted with the side wall of the chute 13, and the upper end of the fixed rod 5 is fixedly connected with a slide rail 6, and the number of the slide rails 6 is two One, the inner surface of the two slide bars is slidably equipped with a slide cylinder 7, and the slide rail 6 is fixedly connected with a limit block 8 at one end of the fixed rod 5, so as to prevent the slide cylinder 7 from sliding out of the slide rail 6 and play a position-limiting role.

[0029] Specifically, a fixed block ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com