Loop transfer needles capable of being automatically restored and loop transfer mechanism with loop transfer needles

A technology of automatic reset and transfer needle, which is applied in the direction of flat knitting, knitting, weft knitting, etc. High needle precision and the effect of simplifying the transfer mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0025] Example.

[0026] see Figure 1 to Figure 13 .

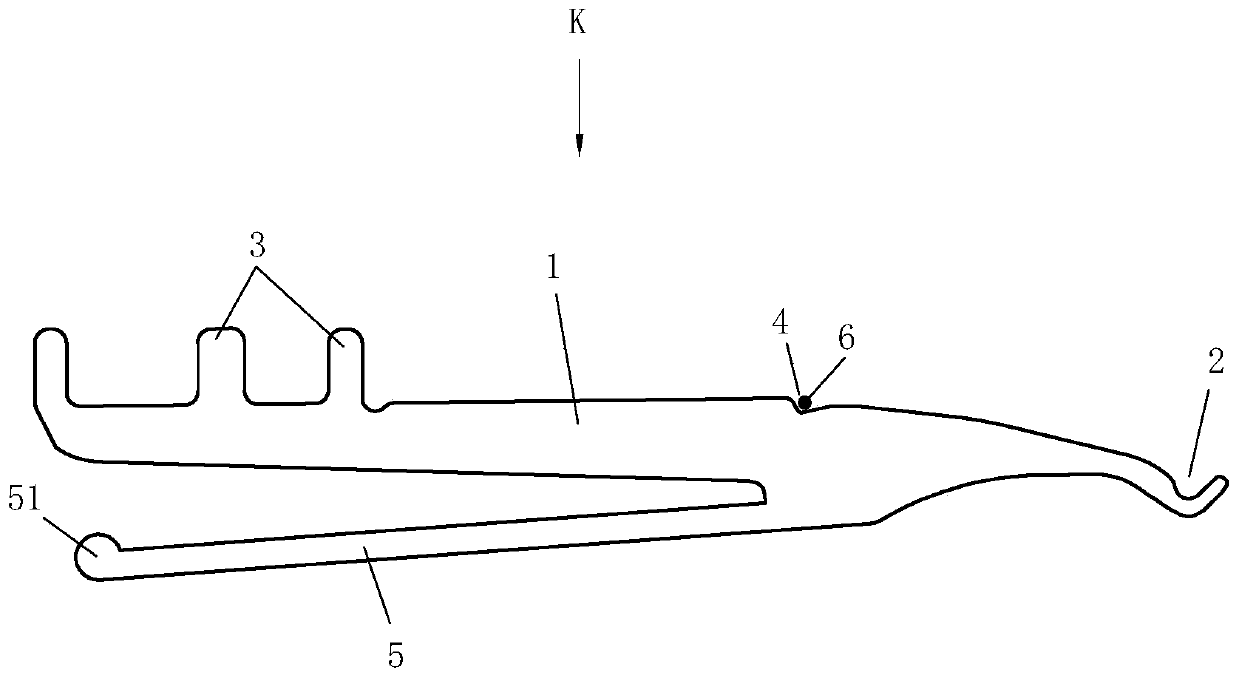

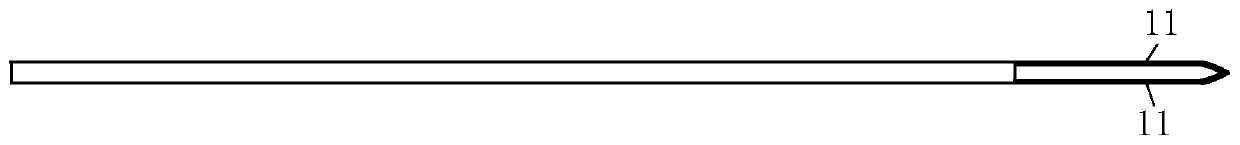

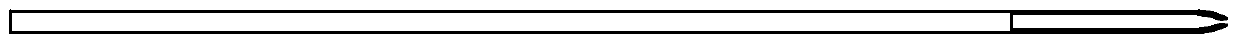

[0027] figure 1 Shown is the side structural view of the transfer needle that can be automatically reset. The transfer needle is installed in the needle groove of the transfer needle bed 9. The transfer needle includes a needle body 1, and a needle selection device is provided on one side of the needle body 1. The heel 3 and the limit groove 4, the other side of the needle body 1 is connected with the reset spring 5, and the needle selection butt 3, the needle body 1 and the reset spring 5 are integrally formed and processed.

[0028] In this embodiment, the needle body 1 is divided into a rear part, a middle part and a front part; there are two selector but...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com