Cooling protection type multi-plastic-film injection molding technology

A film and process technology, applied in the field of cooling and protective multi-film injection molding process, can solve the problems of poor automotive trim, melting and deformation of base materials, deformation of film parts, etc., and achieve the effect of improving the injection molding yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

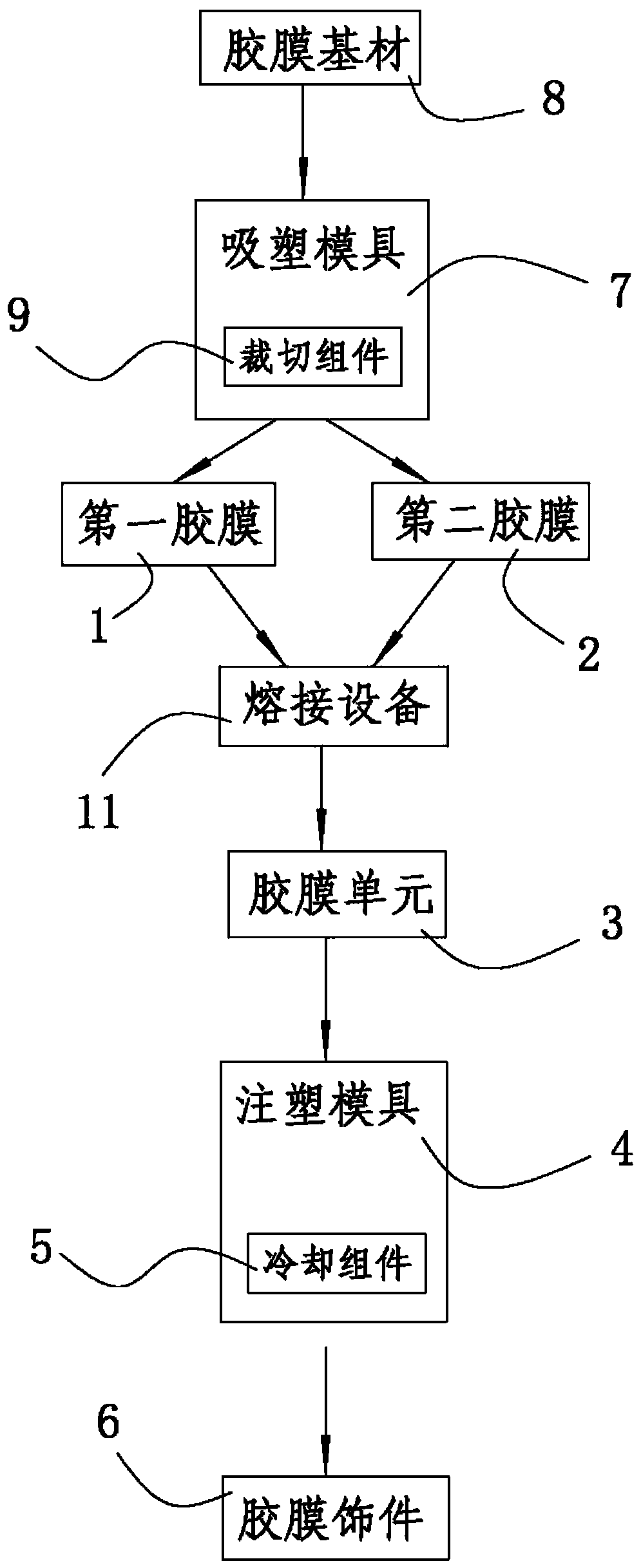

[0033] see figure 1 and figure 2 Shown, a kind of cooling protective type multi-adhesive film injection molding process of the present invention comprises the following steps:

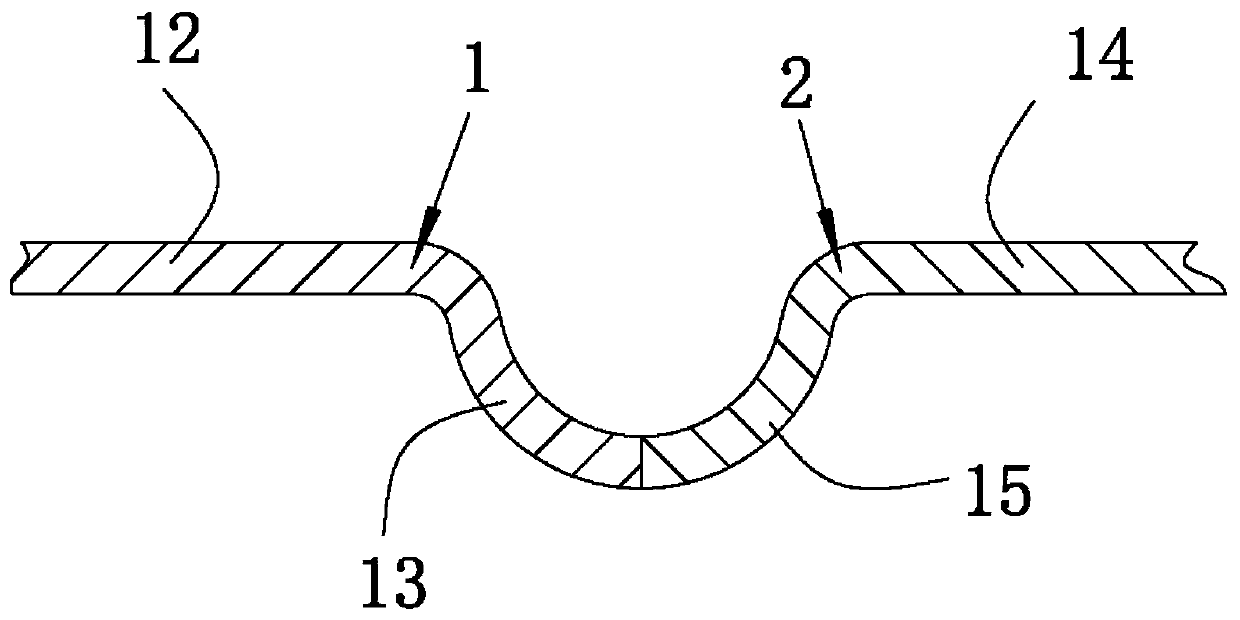

[0034] A first adhesive film 1 and a second adhesive film 2 are provided, the first adhesive film 1 has a first main body portion 12, the second adhesive film 2 has a second main body portion 14, and the first main body portion 12 and the second main body portion 14 have The patterns, graphics or colors are different. For example, the color of the first main body part 12 is silver, and the color of the second main body part 14 is black. Graphics or colors are used to decorate the car, and the first film 1 and the second film 2 are combined to form a car logo 3;

[0035] An injection mold 4 is provided, and the vehicle logo 3 is put into the injection mold cavity of the injection mold 4, and the injection mold 4 has a glue inlet communicating with the injection mold cavity;

[0036] Provide a coolin...

Embodiment 2

[0050] see figure 1 and figure 2 As shown, the cooling assembly 5 includes a cooling hole arranged on the injection mold 4, the cooling hole is used to communicate with the external cooling device, and the cooling device is used to input the external cooling fluid (such as cooling liquid, cooling oil or cooling fluid) into the cooling hole. Cooling gas, etc.), the cooling fluid passes through the injection mold 4 to reduce the temperature of the vehicle logo 3.

[0051] After the vehicle logo 3 is put into the injection mold cavity, the injection mold 4 completes the mold clamping, and then the cooling device injects cooling fluid into the cooling hole, and the cooling fluid passes through the injection mold 4 to the first film 1 or the first film 1 of the vehicle logo 3 / and the second adhesive film 2 are cooled, and then the external molten plastic is injected into the injection mold cavity through the glue inlet, and the cooling fluid is used to cool the vehicle logo 3 t...

Embodiment 3

[0054] see figure 1 and figure 2 As shown, the first bonding edge 13 of the first adhesive film 1 and the second bonding edge 15 of the second adhesive film 2 are bonded and fixed together by glue, and the first adhesive film 1 and the second adhesive film 1 are bonded together by glue. The film 2 is bonded and fixed together, which simplifies the fixing structure between the first bonding edge 13 and the second bonding edge 15, and improves the connection efficiency between the two bonding edges.

[0055] The rest of this embodiment is the same as that of Embodiment 1, and the features not explained in this embodiment are explained in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com