Silk wadding quilt cutting platform device with adjustable light intensity and scale marks

A cutting platform and photometric adjustment technology, applied in the cutting of lighting devices, lighting devices, textile materials, etc., can solve the problems of inaccurate cutting, uncoordinated appearance and quality, and waste of materials, so as to improve accuracy and efficiency and facilitate cutting work Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

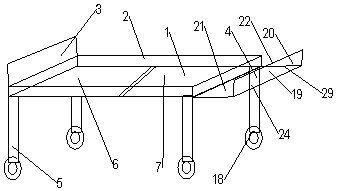

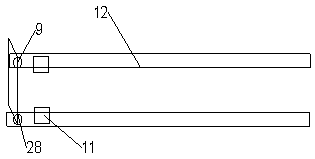

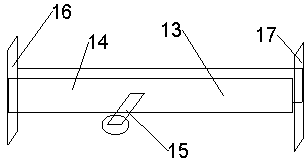

[0015] Such as Figure 1 to Figure 4 As shown, the present invention is a silk cotton quilt with a scalar scale photometric adjustment cutting platform device, including a cutting platform 1, a guardrail frame 2, a measuring slider device 3, a placing space table 4 and a traveling assembly 5, and the cutting platform is 1 minute It is composed of a cutting platform 1 6 and a cutting platform 2 7. The measuring slider device 3 includes a measuring plate 8, a slider wheel 9, a handle 10 and a fixing block 11, and the placing space table 4 moves through guide rails. Connected to the bottom surface of one end of the cutting platform 1, the other end of the cutting platform 1 is provided with a measuring slider device 3, the surface of the upper part of the cutting platform 1 is connected with a guardrail frame 2 by screws, and the bottom of the surface of the guardrail fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com