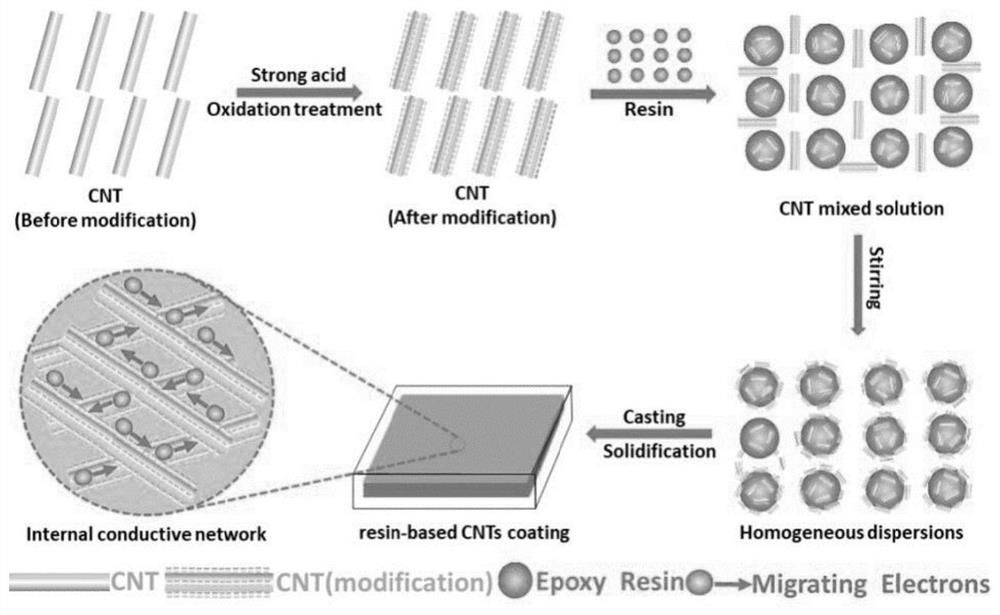

A kind of preparation method of ultrathin carbon nanotube wave absorbing coating material

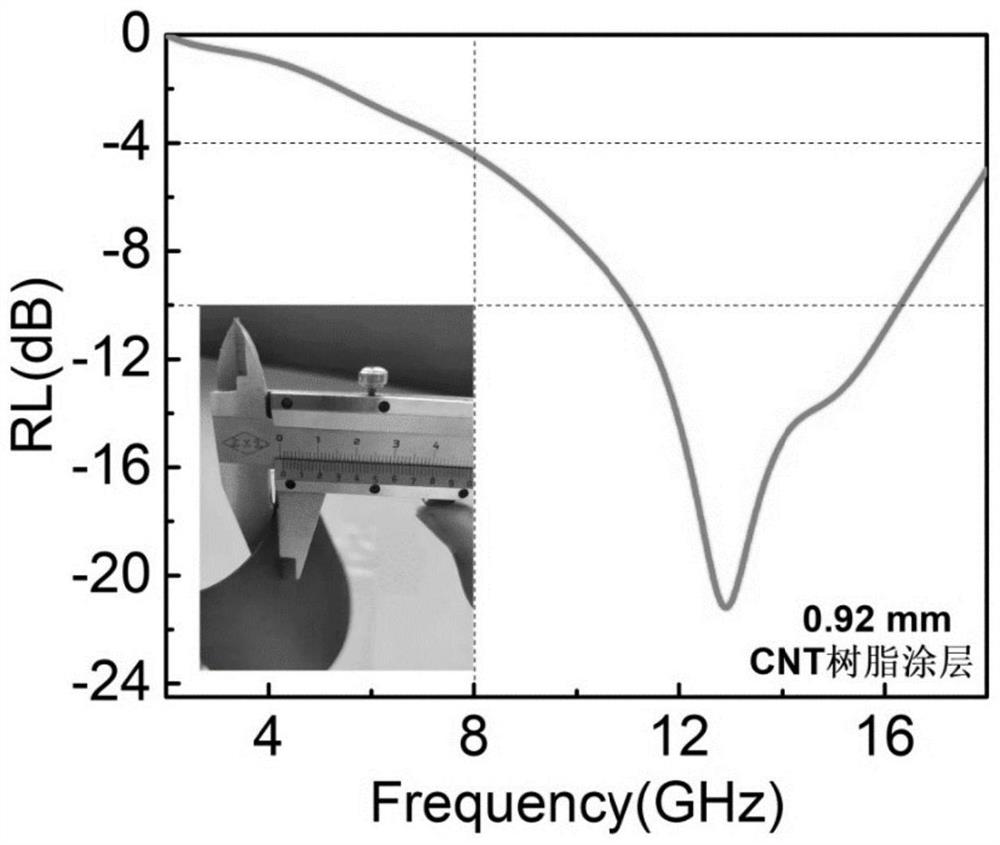

A carbon nanotube and wave-absorbing coating technology, which is applied in the field of preparation of ultra-thin carbon nanotube wave-absorbing coating materials, can solve the problems of complex coating preparation process, limited wave-absorbing performance, long production cycle, etc. The process is simple and mature, the microwave absorption performance is not reduced, and the weight is reduced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

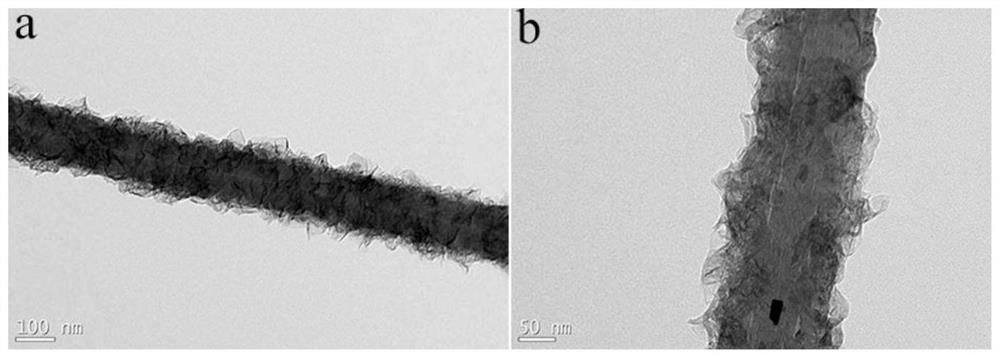

[0037] (1) Add 4 g of carbon nanotube powder into a mixed solution of 320 mL of concentrated sulfuric acid and concentrated nitric acid, stir magnetically for 0.5 h in an ice-water bath environment, then add 12 g of potassium permanganate (slowly added), and continue stirring for 2 h;

[0038] (2) Adjust the temperature of the water bath to 30°C, stir magnetically for 4 hours, add 400 mL of deionized water for dilution (slow drainage), then add 120 mL of hydrogen peroxide solution (5.0%), and stir for 0.5 hours;

[0039] (3) Suction filter the mixed solution prepared in step 2 for 4 times, wash it with deionized water for 5 to 6 times, add hydroquinone (mass ratio to CNTs is 2:1) and stir for 10 minutes, seal it, and then place it in In a constant temperature drying oven, after heating to 100°C, keep the constant temperature for 12 hours;

[0040] (4) The mixed solution in step 3 is taken out, suction filtered 3 times, then washed 4 times with deionized water, then placed in a...

Embodiment 2

[0045] (1) Add 4 g of carbon nanotube powder into a mixed solution of 360 mL of concentrated sulfuric acid and concentrated nitric acid, stir magnetically for 1 h in an ice-water bath environment, then add 16 g of potassium permanganate (slowly added), and continue stirring for 2 h;

[0046] (2) Adjust the temperature of the water bath to 35°C, stir magnetically for 6 hours, add 400 mL of deionized water for dilution (slow drainage), then add 160 mL of hydrogen peroxide solution (5.0%), and stir for 0.5 hours;

[0047] (3) Suction filter the mixed solution prepared in step 2 for 6 times, wash it with deionized water for 5-6 times, add hydrazine hydrate (3:1 mass ratio to CNTs) and stir for 15 minutes, then seal it, and then dry it at constant temperature In the box, after heating to 25°C, keep the constant temperature for 14h;

[0048] (4) Take out the mixed solution in step 3, filter it twice, wash it three times with deionized water, and then place it in a freeze dryer for v...

Embodiment 3

[0053] (1) Add 4 g of carbon nanotube powder into a mixed solution of 400 mL of concentrated sulfuric acid and concentrated nitric acid, stir magnetically for 1 h in an ice-water bath environment, then add 20 g of potassium permanganate (slowly added), and continue stirring for 1.5 h;

[0054] (2) Adjust the temperature of the water bath to 30°C, stir magnetically for 8 hours, add 400mL deionized water for dilution (slow drainage), then add 200mL hydrogen peroxide solution (5.0%), and stir for 0.5h;

[0055] (3) Suction filter the mixed solution prepared in step 2 for 5 times, wash it with deionized water for 5 to 6 times, add hydroiodic acid (4:1 mass ratio to CNTs) and stir for 15 minutes, seal it, and then place it at a constant temperature In the drying oven, after heating to 20°C, keep the constant temperature for 16 hours;

[0056] (4) The mixed solution in step 3 was taken out, suction filtered 4 times, then washed 6 times with deionized water, then placed in a freeze d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com