A method for preparing dehydrated titanium gypsum and products prepared therefrom

A technology of titanium gypsum and free water, applied in chemical instruments and methods, inorganic chemistry, calcium/strontium/barium sulfate, etc., can solve the problems of difficult research, high water content of titanium gypsum, and small particle size of titanium gypsum, etc. To achieve the effect of environmental protection and non-toxicity of reagents, stable dehydration effect, and increase of added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

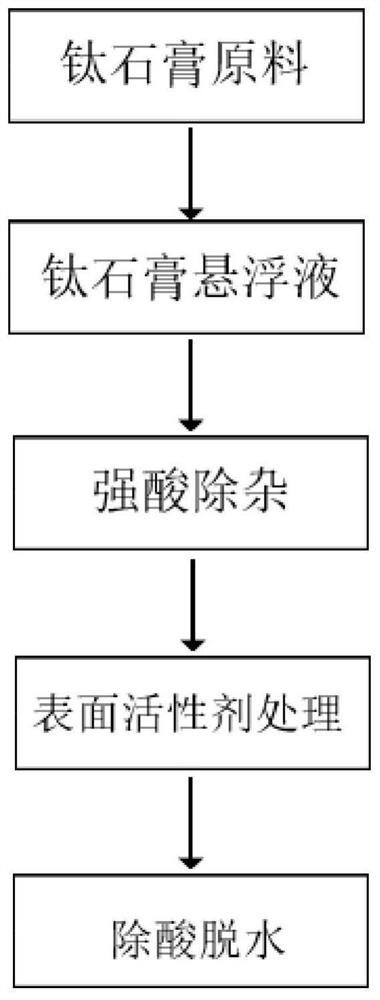

[0049] This embodiment prepares a kind of dehydrated titanium gypsum, and its technological process is as follows figure 1 Shown, its preparation method is:

[0050] (1) Add water to the fresh Sichuan Longmang titanium gypsum raw material with a free water content of 50.3% and a purity of 69%, and mix the titanium gypsum raw material and water at a mass ratio of 1:4 to obtain a titanium gypsum suspension;

[0051] (2) Add sulfuric acid with a concentration of 1mol / L to the titanium gypsum suspension, the mass ratio of the titanium gypsum suspension to sulfuric acid is 8:1, stir and mix, the stirring speed is 300r / min, the stirring time is 4h, pickling The pH value of the titanium gypsum suspension is 2;

[0052] (3) Add betaine surfactant to the pickling titanium gypsum suspension, the addition is 1% of the total mass of the pickling titanium gypsum suspension, stir to obtain a mixed solution, the stirring speed is 300r / min, and the stirring time is 1h;

[0053] (4) Suction...

Embodiment 2

[0055] This embodiment prepares a kind of dehydrated titanium gypsum, and its technological process is as follows figure 1 Shown, its preparation method is:

[0056] (1) Add water to the fresh Sichuan Longmang titanium gypsum raw material with a free water content of 50.3% and a purity of 65%, and mix the titanium gypsum raw material and water at a mass ratio of 1:6 to obtain a titanium gypsum suspension;

[0057] (2) Add sulfuric acid with a concentration of 2mol / L to the titanium gypsum suspension, the mass ratio of the titanium gypsum suspension to sulfuric acid is 15:1, stir and mix, the stirring speed is 300r / min, the stirring time is 4h, pickling The pH value of the titanium gypsum suspension is 1;

[0058] (3) Add fluorocarbon surfactant to the pickling titanium gypsum suspension, the addition is 1% of the total mass of the pickling titanium gypsum suspension, stir to obtain a mixed solution, the stirring speed is 300r / min, and the stirring time is 1h;

[0059] (4) S...

Embodiment 3

[0061] This embodiment prepares a kind of dehydrated titanium gypsum, and its technological process is as follows figure 1 Shown, its preparation method is:

[0062] (1) Add water to the fresh Sichuan Lomono titanium gypsum raw material with a free water content of 50.3% and a purity of 67%, and mix the titanium gypsum raw material with water at a mass ratio of 1:8 to obtain a titanium gypsum suspension;

[0063] (2) Add sulfuric acid with a concentration of 1mol / L to the titanium gypsum suspension, the mass ratio of the titanium gypsum suspension to sulfuric acid is 5:1, stir and mix, the stirring speed is 300r / min, the stirring time is 4h, pickling The pH value of the titanium gypsum suspension is 3;

[0064] (3) Add fluorocarbon surfactant to the pickling titanium gypsum suspension, the addition is 1% of the total mass of the pickling titanium gypsum suspension, stir to obtain a mixed solution, the stirring speed is 300r / min, and the stirring time is 1h;

[0065] (4) Suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com