Punching device for agricultural planting

A punching device and agricultural technology, applied in agriculture, planting methods, fertilization devices, etc., can solve the problems of reduced operation efficiency, low efficiency, and no improvement of punching efficiency, so as to avoid hole collapse, improve operation efficiency, and improve The effect of the hole punch effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

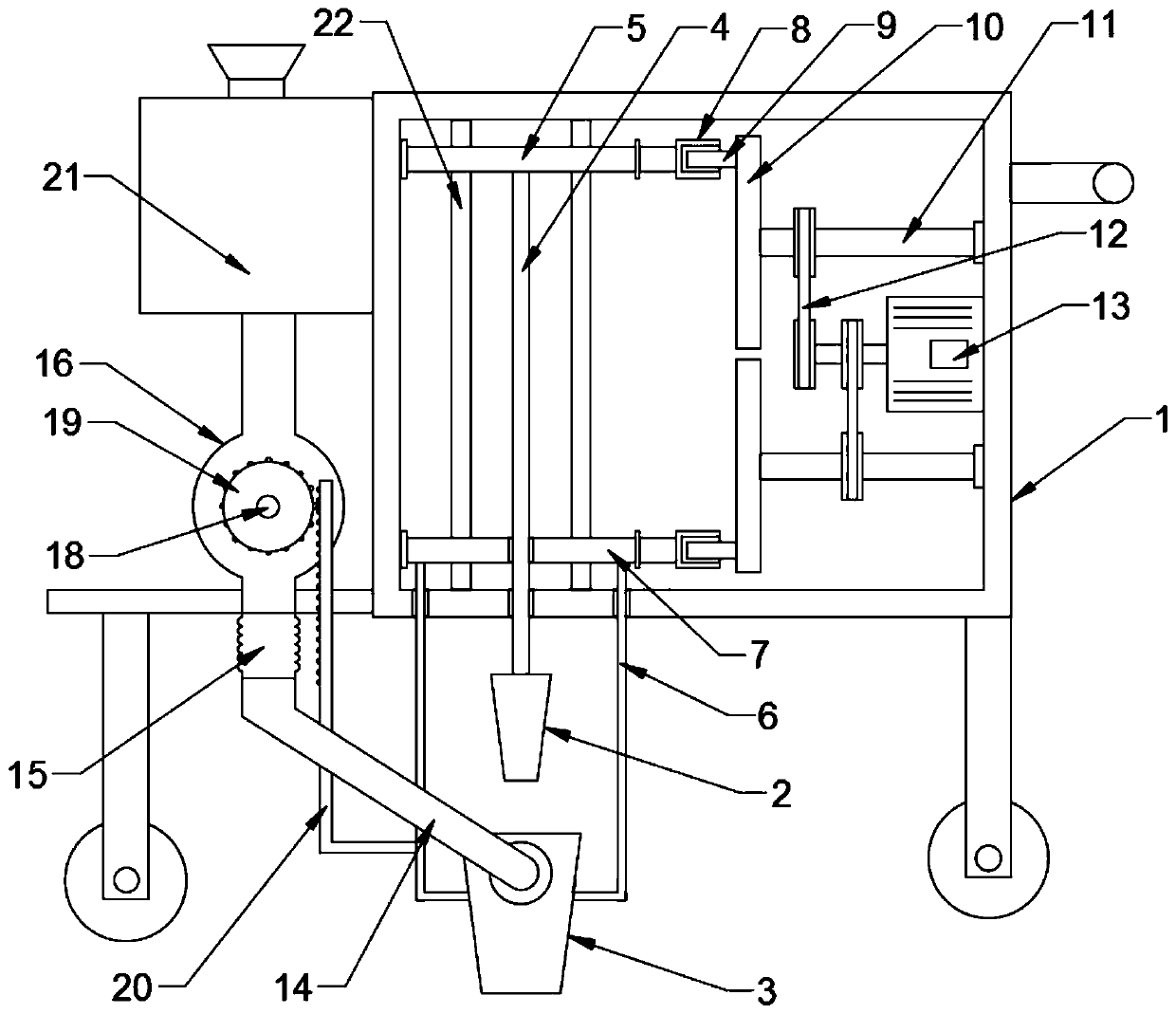

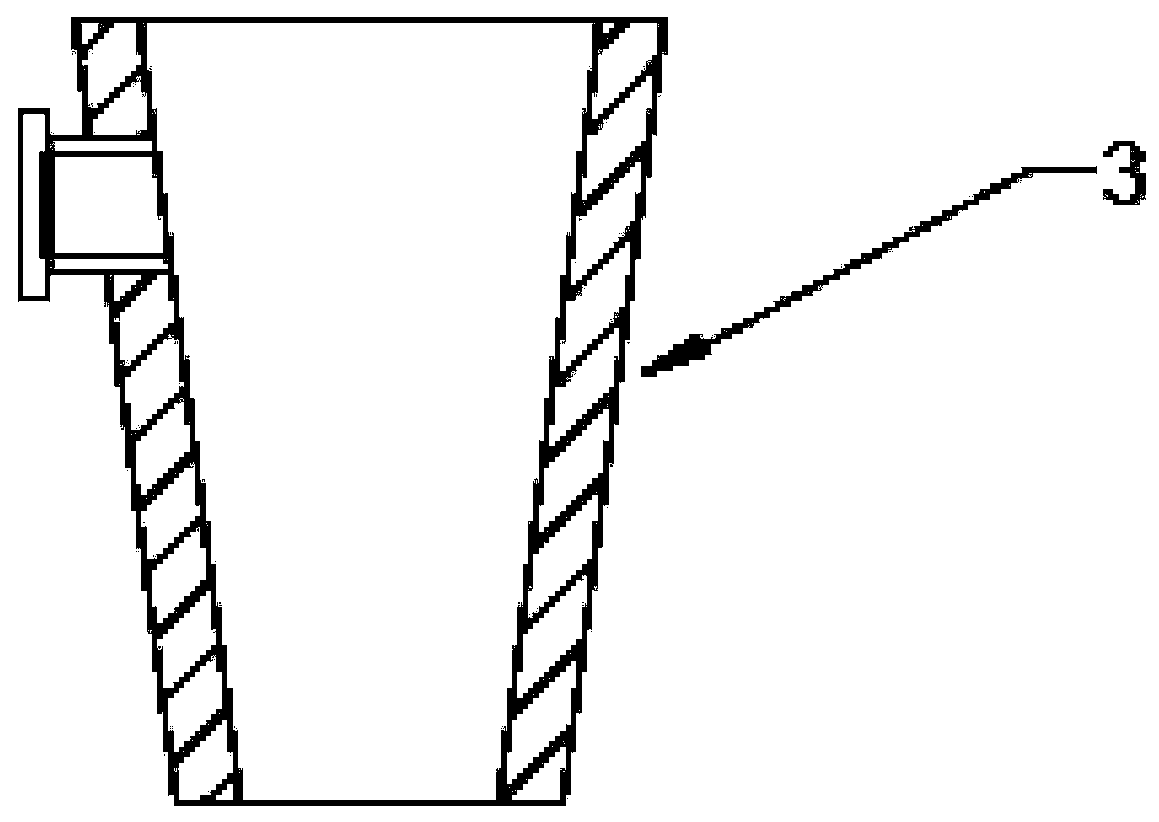

[0021] see Figure 1-4 , in an embodiment of the present invention, a punching device for agricultural planting, comprising a frame 1; a punching cone 2 is provided below the frame 1, and the punching cone 2 is a solid circular frustum and the diameter of the lower end is smaller than the diameter of the upper end. The upper end of the punching cone 2 is connected with the upper lifting plate 5 through the first connecting rod 4; the bottom of the punching cone 2 is provided with a reaming cylinder 3, the reaming cylinder 3 is a hollow circular table tube with upper and lower openings, and the opening at the lower end of the reaming cylinder 3 The diameter is greater than the diameter of the upper end of the perforating cone 2, so that the perforating cone 2 can pass through the reaming cylinder 3; the reaming cylinder 3 is fixedly connected with the lower lifting plate 7 by the second connecting rod 6; the upper lifting plate 5 and the lower lifting plate 7 are all run throug...

Embodiment 2

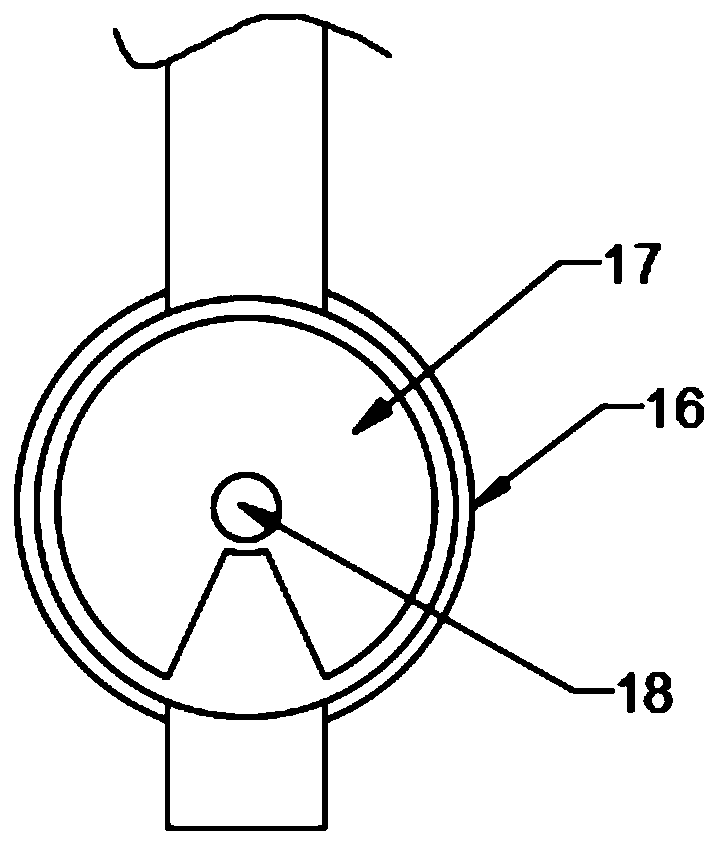

[0024] The difference between this embodiment and Embodiment 1 is that: the outer wall of the reaming cylinder 3 is hinged with a connecting pipe 14, and the connecting pipe 14 communicates with the inner cavity of the reaming cylinder 3; Material barrel 16, lower material barrel 16 is the cylinder that vertically arranges, and lower material cylinder 16 is nested with lower material roller 17, and lower material roller 17 is provided with fan-shaped gap, rotates in lower material cylinder 16 by lower material roller 17, realizes Material blanking; the upper end of the feeding cylinder 16 is connected with a material box 21, the material box 21 is fixedly connected with the vehicle frame 1, and seeds or granular fertilizers can be filled in the material box 21; the material box 21 is fixedly connected with a shaft Roller 18, shaft roller 18 is connected with driving mechanism, and driving mechanism drives blanking roller 17 to rotate, and then realizes blanking.

[0025] The d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com