Test device for simulating surface rupture deformation of reverse fault under earthquake

A test device, reverse fault technology, applied in the direction of measuring device, soil material test, material inspection product, etc., can solve the problem that large-scale and large-scale fault test cannot be completed well, the load power of loading device is small, and it is difficult to model Box staggered movement and other problems, to reduce casualties and property losses, strong operability, and strong repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

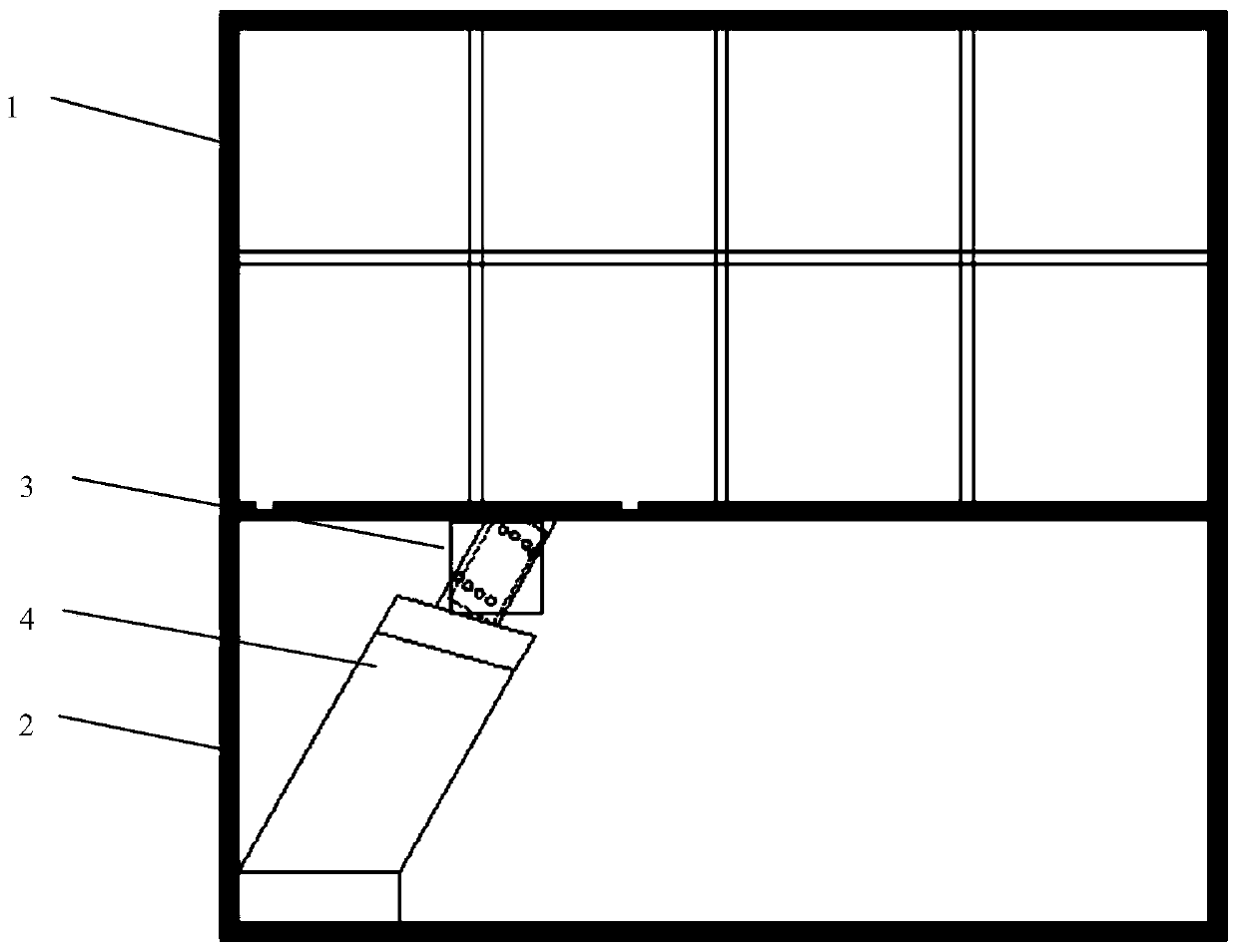

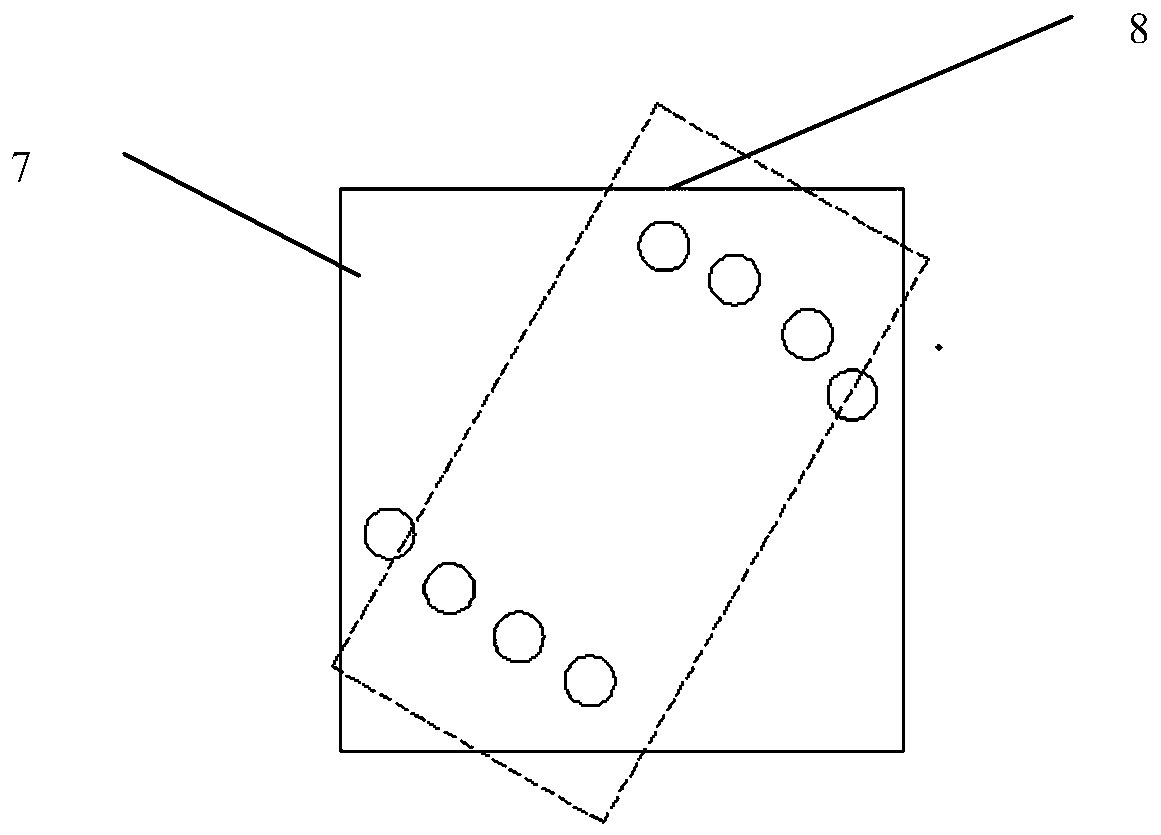

[0024] Such as figure 1 , 2 As shown, a test device for simulating surface rupture and deformation of a reverse fault under an earthquake, including: a reaction floor, a soil box 1, a steel frame 2, a restraining device 3 and an actuator 4,

[0025] The soil box 1 is a rectangular container for loading soil; the soil box 1 is fixed on the shaped steel frame 2, and the bottom of the shaped steel frame 2 is fixed on the reaction floor;

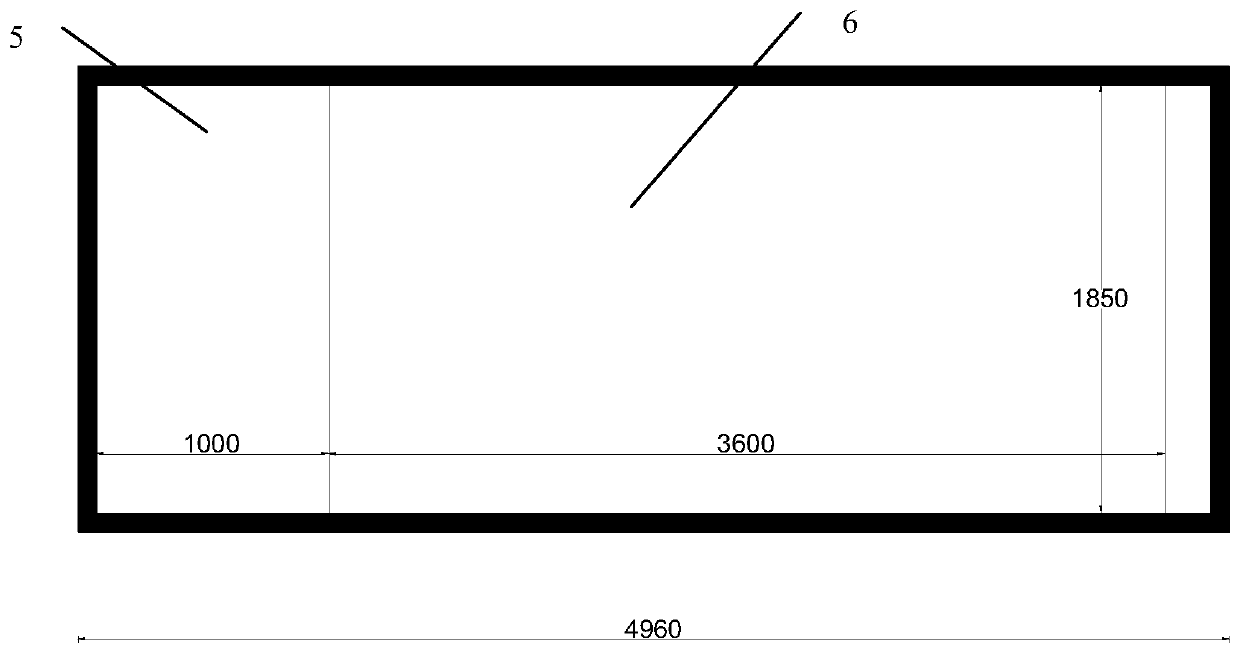

[0026] The bottom plate of the soil body box 1 is divided into two parts, a movable steel plate 5 and a fixed steel plate 6; the surroundings of the movable steel plate 5 are movable, and are softly connected with the surrounding side gaps with canvas to avoid the soil from falling during loading.

[0027] The actuator ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com