Rapid pop-up mobile phone frame transport tray

A technology for transporting pallets and mobile phones, which is used in transportation and packaging, rigid containers, containers, etc., and can solve problems such as the inability of the structure to be placed stably

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

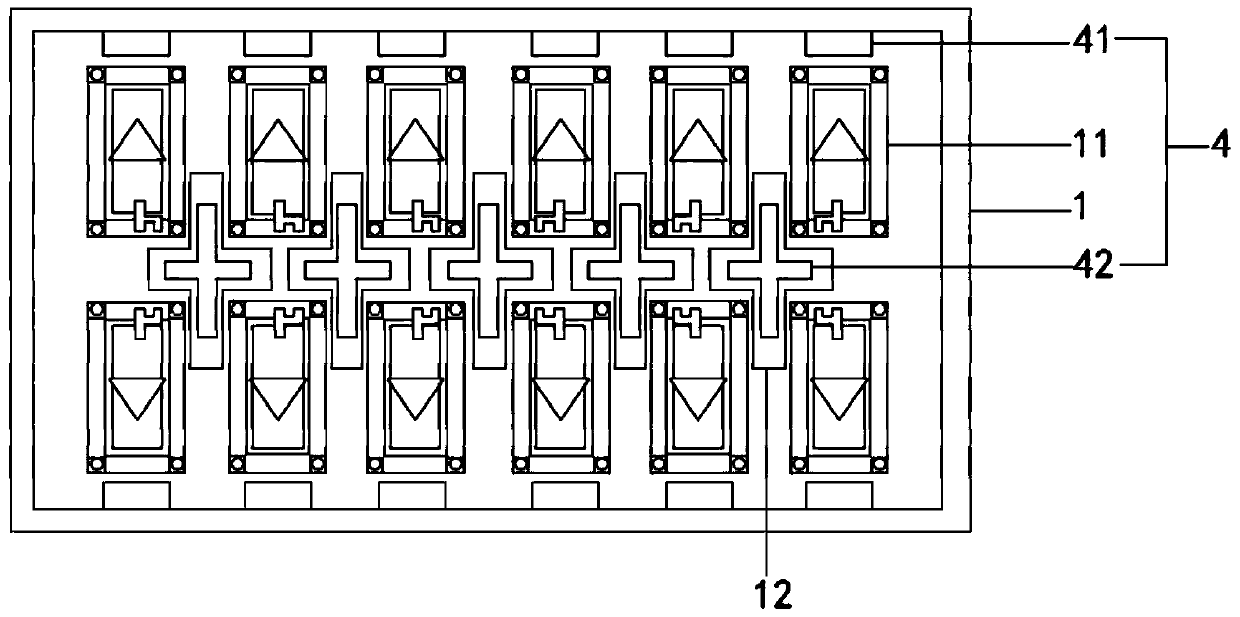

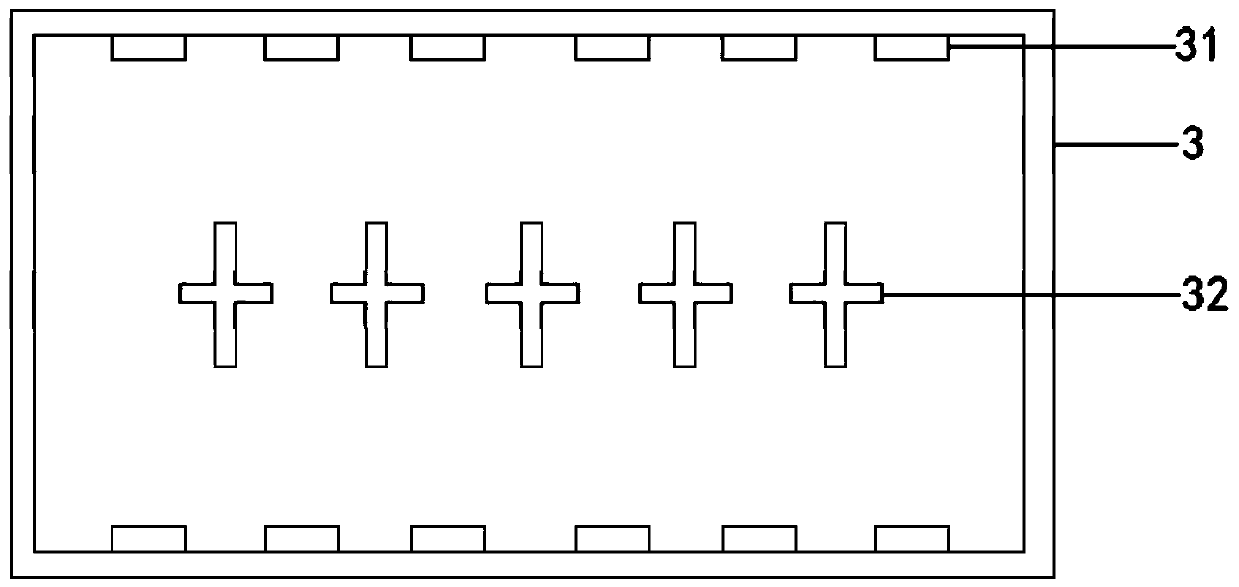

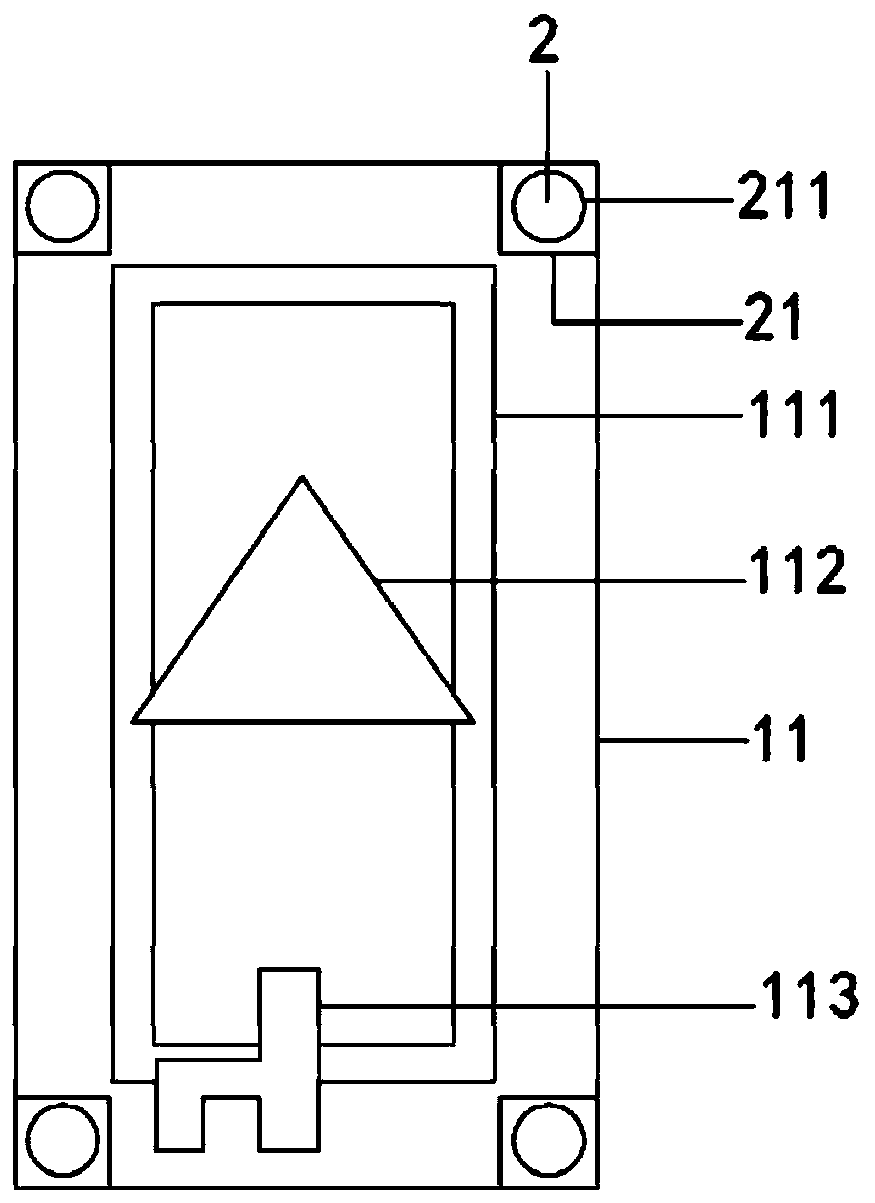

[0023] see Figure 1 to Figure 3 , the figure shows a quick pop-up mobile phone frame transport tray provided by Embodiment 1 of the present invention. First, a transport tray body 1 is provided, and a plurality of rectangular positioning slots 11 are opened in it, and the plurality of rectangular positioning slots 11 are arranged in an array Distributed on the transport pallet body 1, four springs 2 are installed in the rectangular positioning groove 11, and the four springs 2 are distributed on the four corners of the rectangular positioning groove 11, and the natural length of the spring 2 is equal to the depth of the rectangular positioning groove 11, The mobile phone frame is placed on the spring 2 and then pressed into the rectangular positioning groove 11 by the tray cover 3. The clamping assembly 4 includes multiple rectangular notches 41 and multiple cross-shaped clamping grooves 42. The multiple rectangular notches 41 are equidistantly arranged Distributed on the opp...

Embodiment 2

[0028] see Figure 1 to Figure 3 , the figure shows a quick pop-up mobile phone frame transport tray provided by Embodiment 2 of the present invention. On the basis of the above-mentioned embodiments, this embodiment further makes the following technical solutions as improvements: rectangular positioning slot Four springs 2 are installed in 11, and the four springs 2 are distributed on the four corners of the rectangular positioning groove 11, and the natural length of the spring 2 is equal to the depth of the rectangular positioning groove 11, and the mobile phone frame is placed on the spring 2 and then covered by the tray The plate 3 is pressed tightly in the rectangular positioning groove 11, the end of the spring 2 is fixedly equipped with a gasket, the gasket is made of foam material, the gasket can increase the contact area between the spring 2 and the mobile phone frame, and reduce the pressure on the mobile phone frame. It is beneficial to protect the frame of the mob...

Embodiment 3

[0030] see Figure 1 to Figure 3 , the figure shows a quick pop-up mobile phone frame transport tray provided by Embodiment 3 of the present invention. On the basis of the above-mentioned embodiments, this embodiment further makes the following technical solutions as improvements: rectangular positioning slot 11 is provided with a rectangular limiting frame 111, a first positioning component 112 and a second positioning component 113, the first positioning component 112 is located in the middle of the rectangular limiting frame 111, and the second positioning component 113 is located at the bottom of the rectangular limiting frame 111 , the first positioning part 112 is a triangular cylinder, the second positioning part 113 is an h-shaped cylinder, and the circumferences of the triangular cylinder 112 and the h-shaped cylinder 113 are all provided with guide surfaces. Since the deformation direction accuracy of the spring is not enough, it is necessary to Guided by the guide s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com