Lavender harvester

A harvester and lavender technology, applied in the field of crop harvesters, can solve the problems of long harvesting time, short supply, high labor cost, etc., and achieve the effects of uniform growth, meeting production needs, and saving labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

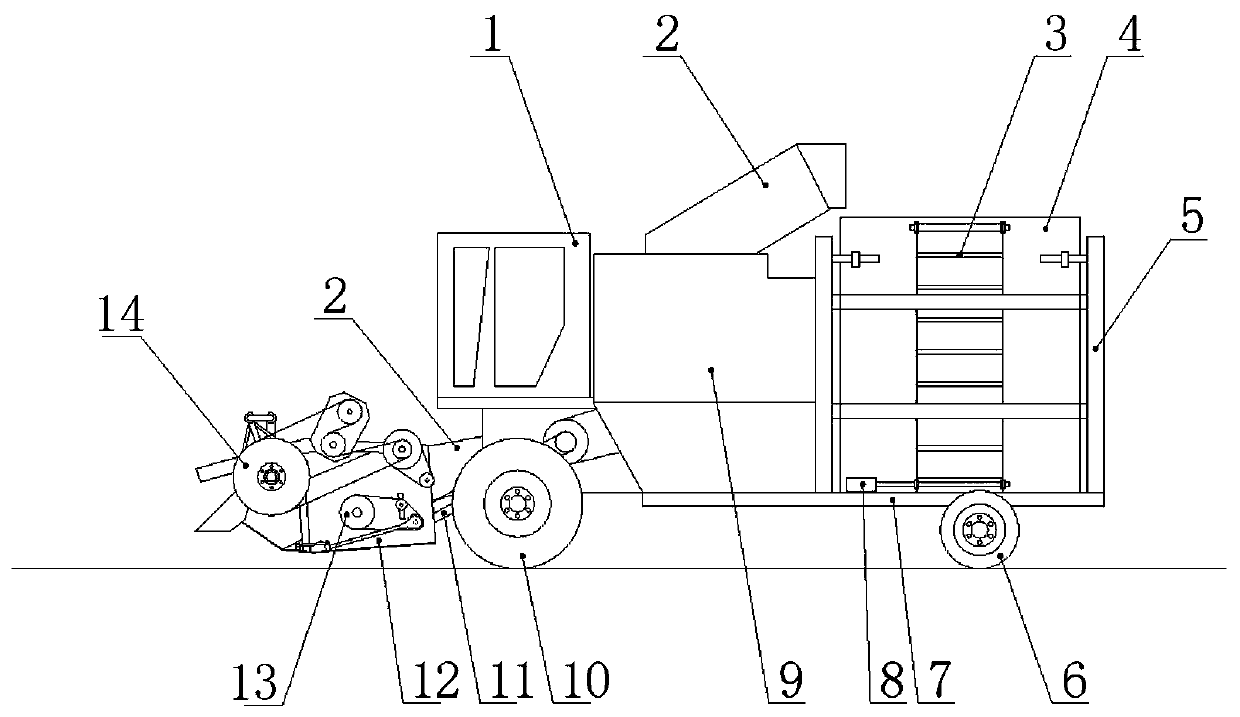

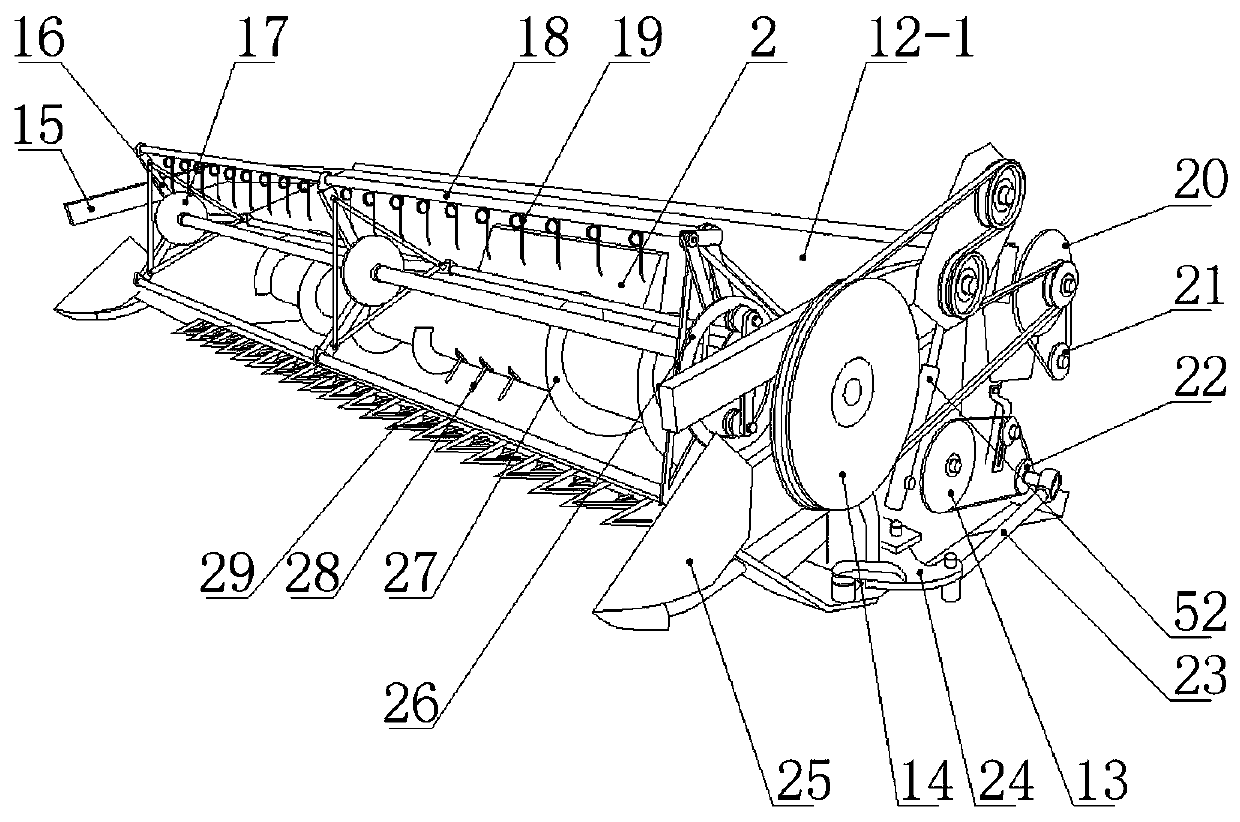

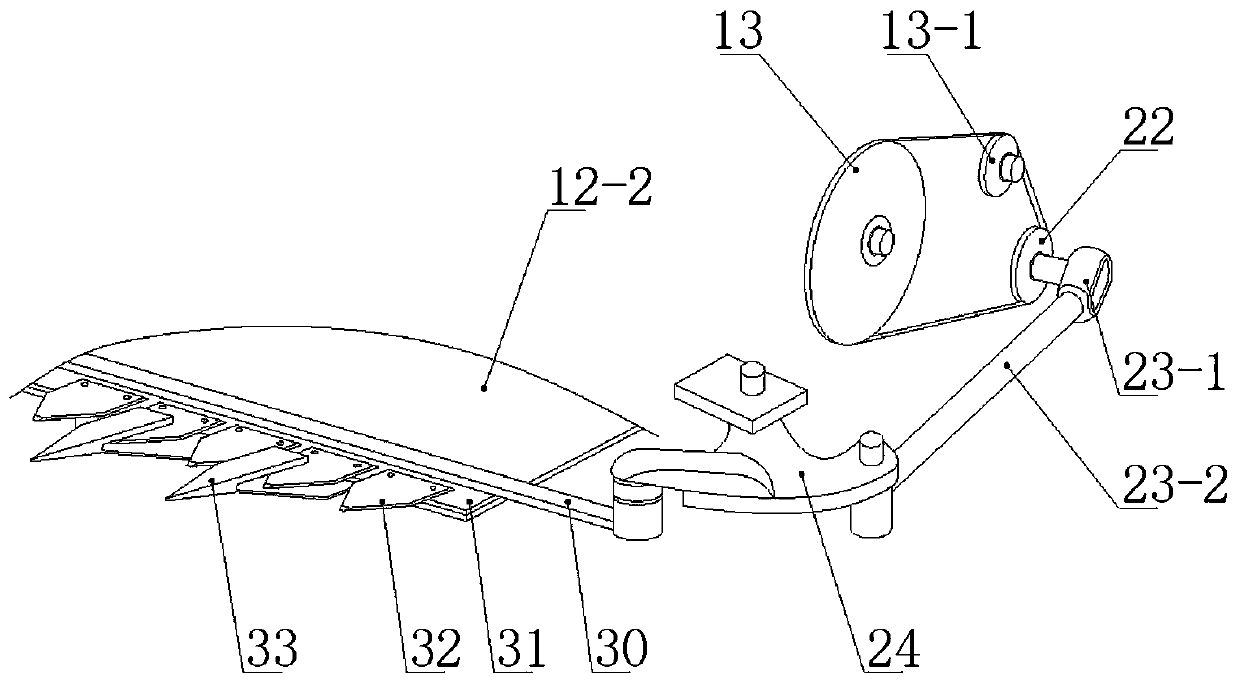

[0039] Example: as figure 1 , 2 As shown, the lavender harvester includes a chassis 7 equipped with a front traveling wheel 10 and a rear traveling wheel 6, a reversible collecting hopper 4 is provided on the rear side of the chassis 7, and a power supply is provided on the chassis 7 on the front side of the collecting hopper 4 Cabin 9, in the power cabin 9, a channel for the feeding channel 2 to pass through is reserved, a platform higher than the chassis 7 is fixed on the front side of the chassis 7, and a cab 1 is set on the platform; the front end of the chassis 7 passes through the first hydraulic arm 11 is hinged with the lower side of the harvesting bucket 12 located on the front side of the chassis 7. The harvesting bucket 12 is provided with a reel frame and a auger 27 from front to back. There are cutting teeth; the rear wall 12-1 of the harvesting bucket on the rear side of the auger 27 is provided with a collecting port, and the collecting port is connected with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com