Permanent magnet adsorption wheel-tracked crawling machine for welding robot

A technology of permanent magnet adsorption and crawling machinery, which is applied to manipulators, welding equipment, auxiliary welding equipment, etc., can solve the problems of simple magnetic circuit, complex mechanical structure and high manufacturing cost of the permanent magnet adsorption unit, so as to reduce the phenomenon of slippage and reduce the mechanical structure. Simple, weight-enhancing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Unless expressly stated otherwise, throughout the specification and claims, the term "comprise" or variations thereof such as "includes" or "includes" and the like will be understood to include the stated elements or constituents, and not Other elements or other components are not excluded.

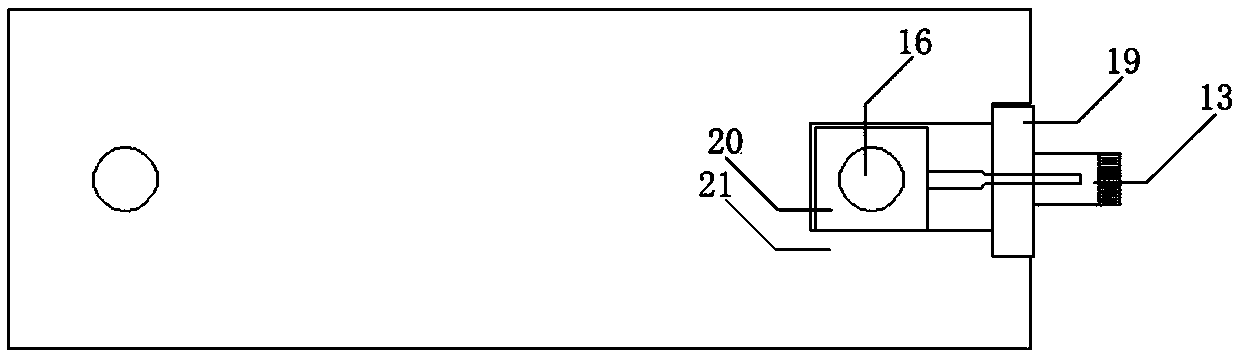

[0018] figure 1 is a top view of an embodiment of the present invention, figure 2 It is a front view of an embodiment of the present invention; the permanent magnet adsorption wheel crawler machinery of the present invention includes: car body 5, left auxiliary permanent magnet adsorption unit 18, right auxiliary permanent magnet adsorption unit 17, left DC servo motor 11. Right DC motor 8, left planetary gear reducer 10, right planetary gear reducer 7, left worm gear reducer 9, right worm gear reducer 6, left driving sprocket 15, right driving Sprocket 2, left driven sprocket 17, right driven sprocket 4, left chain tensioner 13, right chain tensioner 12, permanent magnetic adso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com